Variable Capacitor: Construction, Types and Applications

Did you ever hear your old radio's static shift when you turned the knob? That's a variable capacitor at work. There's no magic here—just clever engineering. By using these parts, you can quickly change the capacitance of the circuit. Manually or electronically. They don't have the same stubbornness as their cousins. Nope. Their flexibility makes them a good choice. It is adjustable. This component can be found in radios, oscillators, transmitters, and so on. Circuits are made more versatile with them because they are flexible. When signal accuracy is crucial, this device is perfect. There shouldn't be too much. The amount should not be too low. It's as easy as dialing it in and locking the frequency.

What is a Variable Capacitor?

Variable capacitors are exactly what they sound like: capacitors with variable capacitances. With these capacitors, you can tweak the capacitance based on your needs, as opposed to fixed capacitors. A shaft can be rotated, plates can be moved, or voltage can be changed in electronic types. Circuits where you need to lock on to a particular frequency, like radios, tend to use them a lot. Electrical signals are adjusted similarly to the focus on a camera.

There is a difference between them all. Metal plates are interleaved with shifting positions in some designs. There are other devices that use materials that stretch or motors that are tiny. There are different ways to store energy between the plates. As a result, you'll be able to control frequency and signal flow better. Okay, they may not be as flashy as microchips or processors, but what if there were no microchips or processors? There would be a bunch of things that wouldn't work, such as your radio not knowing where to tune.

Construction

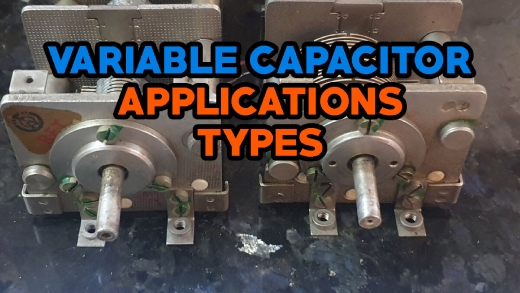

Variable capacitors combine mechanical precision and electrical functionality in a neat little package. The stator and rotor are both made up of stationary plates, called the stator, and movable plates, called the rotor. Aluminum or brass are the most common metals used for these plates. By turning the knob, you move the rotor's plates in or out of alignment with the stator's plates. Capacitance increases with overlap. Less overlap? Lower capacitance, as you might have guessed.

The clever part comes here, though. There is no actual contact between the plates. A dielectric, such as mica or plastic, always acts as an insulator between them. A ceramic or plastic frame keeps the whole setup stable by mounting it on a nonconductive surface. A fine-tuning gear is added to some designs, especially in high-frequency equipment. In addition, the capacitor is connected to the circuit at one or more terminals. Changing the plate area changes capacitance, but the engineering finesse makes it reliable, smooth, and precise. Moreover, you can also learn about CBB61 Capacitors from our website.

Types of Variable Capacitor

Air Gap Variable Capacitor

It's one of the classics. An air-based dielectric is used between its plates, making it a simple, reliable, and clean method. Older radios and analog tuning circuits usually contain this type of circuit. Based on the overlap of the stator and rotor plates, the capacitance changes as the shaft is rotated. There is no fancy material involved here, just good ole' air and metal working their magic. Stability is its strong suit, but compactness is not. The fact that air is the insulating material makes it most applicable for applications involving low voltages and high frequencies.

Vacuum Variable Capacitor

Now we're getting into high-end territory. The voltage and power handling on these is serious. In place of air, they're enclosed inside vacuum tubes. Why? Due to the fact that vacuum is a better insulator, it reduces losses and enables better control. They are found in industrial RF transmitters, ham radio equipment, and huge broadcast stations. For basic chores, these guys are overkill, but when power and precision are important, they are the go-to guys.

Trimmer Capacitor

Despite its size, it is powerful. Fine-tuning is performed with trimmer capacitors, which are tiny adjustable capacitors. They are usually tweaked once during setup or calibration, not by twisting knobs. PCBs, where space is limited and precision is critical, often have these components. An example of this might be a trimmer that calibrates the frequency of a TV tuner. As long as they're used for little touch-ups when you're building or repairing, they won't need constant adjustment.

Ceramic Variable Capacitor

They are like hybrids. Ceramic dielectrics offer greater stability and smaller size than air-gap types. The solid dielectric material gives a more stable capacitance, even with changes in temperature, regardless of whether they are trimmers or knobs. Devices that require both reliability and compactness frequently use them.

Electrostatic or MEMS-Based Variable Capacitor

Welcome to the micro-world. Silicon chips are etched with movable structures to create MEMS capacitors. To change capacitance, these devices use microscopic arms and voltage instead of knobs or plates. Smartphones, sensors, and wearable tech all use them in places where traditional mechanical parts wouldn't fit. Their precision, speed, and ease of integration make them ideal for digital electronics.

Applications

Radio Tuning Circuits

There is probably no better way to describe variable capacitors than to explain their role in old-school radio tuning. Have you ever tuned in to your favorite station? Here's a picture of the variable capacitor that adjusts the tuning circuit's resonant frequency. When you change the capacitor's capacitance, you can shift the circuit's frequency range to lock onto the desired signal. Despite its simplicity, this simple but effective mechanism still powers many analog radios and communication receivers.

Oscillators and Signal Generators

Variable capacitors help tune frequencies generated by oscillators - like sine, square, and triangle waves. In these circuits, the capacitor is often connected to an inductor or resistor in order to achieve the desired output. Signal frequency can be precisely controlled by adjusting the capacitance. Waveform generators and lab test equipment use variable capacitors to provide engineers with hands-on control over waveforms.

Antenna Matching Networks

An important part of RF communication systems is impedance matching. Optimal power transfer requires a matched antenna and transmitter or receiver. Using variable capacitors, you can modify the match between components to make it just right. Signal strength, clarity, and efficiency are all assured through the use of these capacitors, which allow for real-time adjustments to account for changes in environmental conditions.

Filters and Equalizers

Filters can be used in audio applications as well as radio frequency applications. They use variable capacitors to adjust the resonance or cutoff point. Audio equalizers may have tone controls that can be tweaked. In RF filters, they allow certain bands to be selected or suppressed. The ability to adjust for different environments or tasks is crucial when designing systems.

Measuring Instruments

A variable capacitor may be used as part of the sensing or calibration system in some precision instruments. Depending on the model, capacitance bridges and LCR meters (used to measure inductance, capacitance, and resistance) may have adjustable capacitors. Circuits can be balanced, unknown components can be compared, or readings can be fine-tuned by tweaking capacitor values.

Educational and Testing Kits

Various capacitors are excellent teaching tools in classrooms, laboratories, and hobbyist kits. Using them, one can demonstrate how capacitance, frequency, and circuit behavior are related. Students are able to see how circuits respond to changes by physically adjusting components.

Satellite and Space Communication

A variable capacitor (usually MEMS-based or electronically controlled) plays a role in dynamic frequency control in satellite systems, especially when remote tuning is required. By adjusting antennas and circuits, they allow communications to remain stable as orbital conditions change.

Faqs

Question 1: What are the advantages of variable capacitors?

Answer: They’re flexible. Super handy too. You get to tweak the capacitance as you need it—no soldering, no swapping parts. Especially in RF circuits, they shine. You turn a knob, and boom—your signal locks in. That level of control? Pretty essential when you’re chasing precision. So yeah, they might be small, but don’t let that fool you. Their job’s big.

Question 2: What are the units for variable capacitors?

Answer: Farads. That’s the SI unit. But let’s be real—no one’s tossing around full farads in these circuits. Way too big. You’ll see stuff like microfarads (µF) or even tinier—picofarads (pF). Engineers work with those because that’s where the action is. So while the unit stays “farad,” the scale gets small. Really small.

Final Verdict

Some of the most vital tuning and signal control functions in electronics are powered by variable capacitors, which may not always get the attention they deserve. With their adjustability, they bring flexibility as they tune a radio station, match an antenna, and calibrate precision instruments. Regardless of technology advances, variable capacitors continue to adapt and remain relevant. The component is tiny, but it makes a big difference.