What is a Ceramic Capacitor and How Does it Work?

It's common to encounter the odd-in-sighted colorful components on circuit boards. Meet ceramic capacitors-small devices, yet with magnetic functionality in the electrical circuits of modern electronics. Right from Smartphones to Cars, ceramic capacitors work stealthily in the background to insure the smooth inflow of modernization.

What are Ceramic Capacitors?

Ceramic capacitors are unresistant electronic factors used to store and release electrical energy. This very small device has two conductive plates separated by the ceramic dielectric material that supplies charge to a circuit until it is required-applied in several ways throughout electronic circuits.

Types of Ceramic Capacitors

There are two main types of ceramic capacitors, videlicet multilayer and single-subcaste bones. Of these, multilayer ceramic capacitors(MLCCs) are the most extensively used. An MLCC has alternate layers of ceramic dielectric and essence electrodes. Single-layer ceramic capacitors may be more appropriate in certain high-frequency applications but tend to be less popular.

Advantages over Other Capacitor Types

Ceramic capacitors hold considerable advantages over their competing packs. They offer high temperature stability, low inductance, high capacitance-to-volume ratio, allow use in AC circuits without regard to polarity, are cheaper, long-living, and very versatile for use in countless electronic applications.

Common Applications of Ceramic Capacitors

Due to their versatility and reliability, ceramic capacitors are widely utilized across electronic devices. They are used in all electronic devices, from the power supplies that help control voltage fluctuations to digital circuits that serve as decoupling components, which serve to minimize noise and allow stable operation.

Understanding Ceramic Capacitors

Ceramic Dielectric Material

At the core of every ceramic capacitor lies its essential element: ceramic dielectric material. This specialty ceramic substance acts as an insulator between its two conductive plates, enabling the capacitor to store electrical charge efficiently in compact form. Common examples include barium titanate, titanium dioxide, and various metal oxides, chosen due to their high dielectric constants and excellent insulating properties for efficient charge storage in a small volume.

Conductive Plates

On either side of a ceramic dielectric you'll find thin conductive plates made of metals such as silver or nickel that serve to store and distribute an electrical charge. They're arranged alternatingly layers so as to maximize charge storage surface area while decreasing size while minimising cost and size constraints in capacitor design.

Terminal Connections

To connect ceramic capacitors to an electrical circuit, terminals from conductive metal must be attached to their conductive plates. Designed for reliable connections, the terminals can take on a variety of forms, such as leads for through-hole mounting or flat pads for the surface mount applications that make these components adaptable for various circuit board designs.

Size and Shape Variations

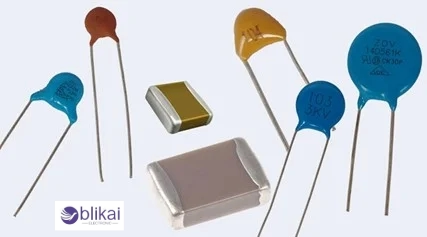

Ceramic capacitors come in an assortment of sizes and shapes designed to suit different applications, from tiny surface-mount components measuring fractions of millimeter to larger through-hole variants that meet specific space and electrical requirements. Common shapes for ceramic capacitors are disc, rectangular, and chip capacitors, each offering distinct mounting advantages as well as performance benefits.

How Ceramic Capacitors Work

Principle of energy storage

Ceramic capacitors store energy in an electric field between two conductive plates. When voltage is applied, electrons migrate towards one plate while leaving others untouched -creating an overall potential difference and acting as the cornerstone of energy storage for ceramic capacitors. This separation of charges provides the basis of energy storage within these capacitors.

Charging and discharging process

To charge, electrons flow from the positive terminal to the negative terminal and create an electric field; charging rate depends on capacitor capacitance and circuit resistance. Discharging releases stored electrons back through the circuit and allows energy storage to release its stored up energy.

Role of the dielectric material

Ceramic dielectric material between the plates plays an essential part in a capacitor's functioning, as it blocks current from flowing between them while permitting electric field passage through. Properties such as permittivity directly affect performance and determine capacitance value.

Capacitance and its measurement

Capacitance being a measure of the capacitance of capacitors to acquire electric charge is expressed in farads. The capacitance of ceramic capacitors depends mainly on plate area, distance between plates, the dielectric stiffness of the ceramic material itself, and the dielectric constant. The capacitance values are usually expressed in picofarads (pF) or nanofarads (nF) per the manufacturer specifications.

Key Characteristics of Ceramic Capacitors

Temperature coefficient

The other interesting property of ceramic capacitors is that they are known as their temperature coefficient, which measures the shift in their capacitance with temperature changes. The unit of the temperature coefficient is in parts per million per degree Celsius (ppm/degC). Different dielectric materials exhibit different temperature coefficients which may be positive, negative, or near zero depending on which ceramic dielectric materials they're composed from.

Voltage ratings

Ceramic capacitors are designed to operate within specific voltage ranges. Their voltage ratings represent the maximum continuous voltage that can safely be applied across them without causing breakdown or failure, making it essential to select a capacitor with a rating higher than your circuit's operating voltage for reliability and longevity.

Capacitance tolerance

Capacitance tolerance defines the chance of permissible divagation from the nominal capacitance value; it can be expressed in colorful ways, like-5,-10, or-20. Tighter tolerances generally indicate better perfection but at an advanced cost; thus, which tolerance range to choose depends on the conditions of the operation.

Frequency response

Ceramic capacitors are most suited for high-frequency operations owing to their low original series resistance(ESR) and equivalent series inductance(ESL); hence, they're generally used in decoupling and filtering operations in high-speed circuits. Note though that effective capacitance may roll off with higher frequencies-this is capacitance roll-off.

Reliability and lifespan

Ceramic capacitors are known for their outstanding reliability and long operational lifespan, even under extreme temperature extremes or mechanical stress. Their absence of liquid electrolytes adds stability over time, making them less prone to drying out or leaking than some other capacitor types.

Choosing the Right Ceramic Capacitor

A. Determining required capacitance

Charging the needed capacitance is the most important consideration when copping a ceramic capacitor. Measured in farads(F), this value is a measure of the capacitor's capability to store electrical charge. To elect an applicable capacitance value for your operation and circuit conditions, divorcing operations might need lower values while power force filtering operations might necessitate advanced values.

B. Considering voltage requirements

Voltage rating is another critical consideration in selecting an ideal ceramic capacitor, as its ability to withstand maximum voltage present in a circuit without becoming damaged is essential for its proper operation. When possible, select one with an expected maximum voltage rating higher than this figure for additional safety measures.

C. Evaluating temperature conditions

Temperature conditions must always be taken into account when choosing ceramic capacitors as they can be sensitive to thermal changes. Different dielectric materials have different temperature coefficients which affect capacitance stability. When dealing with wide temperature ranges or extreme environments, choose capacitors with appropriate characteristics such as the X7R or C0G/NP0 types for maximum performance.

D. Assessing frequency needs

Ceramic capacitor frequency response should always be taken into account when designing high-frequency applications, particularly those using Class 1 dielectrics such as C0G/NP0 for radio frequency (RF) circuitry. For instance, some ceramic capacitors perform better at higher frequencies than others. Class 1 dielectrics like these offer excellent stability and low losses at higher frequencies which makes them suitable for such circuits.

Conclusion

Ceramic capacitors are essential components in modern electronics, providing a unique combination of compact size, reliability, and versatility. From their fundamental structure to operational principles and their widespread usage across industries. Engineers and designers need to understand these devices' key characteristics like temperature stability, voltage ratings and capacitance values in order to choose an optimum ceramic capacitor that suits their specific requirements.

Consider factors like operating environment, frequency requirements and space requirements when selecting a ceramic capacitor for your application. By carefully considering these aspects and matching them to an appropriate ceramic capacitor type, you can ensure optimal electronic designs in terms of performance, efficiency and longevity. Also stay up-to-date on advances in ceramic capacitor technology to take full advantage of its potential in future projects.

Related Articles

Ceramic Capacitor Advancements: Innovations and Applications

Tantalum vs Ceramic Capacitor: What's the Differences?

Film vs Ceramic Capacitor: What's the Differences?

What is an Audio Capacitor and Why Does it Matter?