Polyester vs Polypropylene Capacitors: Explained

Polyester vs Polypropylene Capacitors

We will explore the construction, properties, applications, and key differences between polyester and polypropylene capacitors in this article. So curious to learn more about Polyester vs Polypropylene Capacitors? If yes, then continue reading till the end of this article!

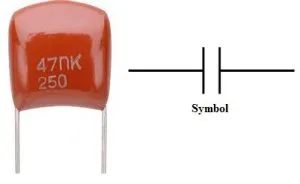

What is a Polyester Capacitor?

What is a Polyester Capacitor

Two metal plates are arranged between a polyester film and an insulator. If the polyester film is not suitable, a metalized film can be used as an alternative. There are capacitors made of polyester that have a capacitance between 1nF -15F, and they work between 50 and 1500 volts. Polyester capacitors are available in tolerance ranges of 5%, 10%, and 20%, and their temperature coefficients are high.

Since these capacitors have a high isolation resistance, they are excellent for storage and coupling. It is not uncommon for these capacitors to function at temperatures close to 150 degrees Celsius, as they are very heat resistant.

Polyester capacitors have a higher capacitance for the same volume than other types, which is why a capacitor with high capacitance can be made in a small volume. It is widely known that polyester capacitors are cost-effective, but they are also widely used. Circuits that use them include audio and oscillator circuits that operate at moderately high frequencies.

Construction

In most cases, aluminum or metallized foil is used as a separation between two metal plates. Capacitors store electric charge using dielectric film as an insulator between the plates. A cylindrical shape can be created by rolling and stacking the plates and films tightly together.

An outer protective coating is applied to the capacitor to protect it from environmental factors. As a result of this coating, moisture and dust will not be able to damage internal components and the epoxy or polymer material will provide insulation.

Polyester Capacitor Types

Depending on their construction and intended use, polyester capacitors come in a variety of types. Here are a few examples:

Metallized:

One of the capacitor plates is formed by depositing thin metal film directly on polyester film. In applications where space is limited, this compact design is ideal.

Stacked Film:

Capacitors of this type are constructed by alternating layers of polyester film and metal foil. It is possible to handle higher voltages with stacked film capacitors due to their higher capacitance;

Box Type

Plastic or epoxy boxes encapsulate box type capacitors with rectangular shapes. The capacitance values of these capacitors make them ideal for power supply circuits due to their high capacitances

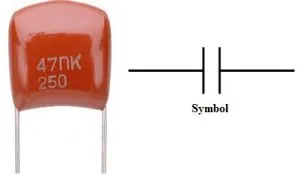

What is a Polypropylene Capacitor?

What is a Polypropylene Capacitor

Capacitors made with polypropylene film as dielectric material are known as polypropylene capacitors. Electrical energy can be stored and released through capacitors, which are electronic components. The electrical properties and reliability of polypropylene capacitors make them an excellent choice for electronic circuits and devices.

Construction

An aluminum or metallized foil plate is sandwiched between two polypropylene films separated by a thin polypropylene film in a polypropylene capacitor. A film acts as a dielectric between the plates, insulating them from one another. Cylindrical or rectangular shapes are formed by tightly rolling or stacking the plates and films.

A polymer or epoxy outer casing protects the capacitor from dust and moisture. Capacitor longevity is ensured by the casing, which provides insulation.

Comparison Between Polyester vs Polypropylene Capacitors:

Stability

In the first polypropylene versus polyester comparison, we have the stability. The ability to maintain the capacitance value of capacitors depends on their stability because capacitors are constantly changing. Despite a wide temperature range, polyester capacitors maintain a stable capacitance. When consistency of performance is critical, polypropylene capacitors are even more reliable than metal capacitors.

Voltage Range

Voltage ranges indicate what voltage a capacitor can handle before it starts to fail. Several volts to several hundred volts are available in polyester capacitors. A polypropylene capacitor will not melt under high voltages, unlike polypropylene capacitors. Because polypropylene capacitors can handle higher voltages, they are ideal for applications requiring high voltages.

Tolerance

Let us know what tolerance you are willing to accept from the stated capacitance value. Capacitors made of polyester can be found with tolerances ranging from 5% to 20%. Its tolerance range, however, is usually between 1 and 5% for polypropylene capacitors. Since polypropylene capacitors have tighter tolerances, they are ideal for applications requiring precise capacitance values.

High dV/dt

In polypropylene vs polyester comparison, Capacitors with dV/dt ratings are capable of handling rapid voltage changes without becoming overly stressed. High voltage transient applications may not be appropriate for polyester capacitors based on their dV/dt rating. Compared to polypropylene capacitors, polypropylene capacitors can handle rapid voltage changes more easily because of their high dV/dt ratings. As a result, polypropylene capacitors are ideal for switching between voltages quickly.

Temperature

Applications with wide temperature fluctuations require capacitors with wide temperature ranges. There is a wide range of common operating conditions for polyester capacitors, from -55°C (-67°F) to +125°C (257°F). As an added benefit, polypropylene capacitors can operate in temperatures ranging from -55°C (-67°F) to +105°C (221°F). Polypropylene capacitors are ideal for applications that experience substantial temperature fluctuations due to their wide temperature range.

Faqs

Question 1: Are polyester capacitors polarized?

Answer: Unlike other capacitors, polyester capacitors do not have polarization, so they can work either way. The negative and positive terminals of electrolytic and tantalum capacitors are polarized. Regardless of their orientation, polyester capacitors work interchangeably in circuits since they are not polarized. Consequently, they make circuit design and assembly easier and more versatile.

Question 2: What is the purpose of using a pF capacitor?

Answer: Circuits that contain capacitors in the picofarad range are commonly called pF (picofarad) capacitors. In addition to coupling and decoupling, timing, filtering, and matching impedances, they are used for various purposes. A large capacitance value is needed to suppress unwanted noise in high-frequency applications, which is one reason why pF capacitors are particularly useful.

Question 3: Do polypropylene capacitors work well for audio?

Answer: Audio applications benefit greatly from polypropylene capacitors. Because of this, they preserve the original characteristics of audio signals while offering low distortion and high signal fidelity. Several components of audio equipment utilize polypropylene capacitors to make their sound as good as possible

Question 4: Are polyester capacitors good?

Answer: There are many applications for polyester capacitors. These devices are affordable, compact, stable, and offer a low dissipation factor. Their application ranges from consumer electronics and power supply circuits to various electronic circuits and devices.

Final Verdict

It is mainly their use that distinguishes polyester capacitors from polypropylene capacitors. The polyester capacitor is used for general applications, while the polypropylene capacitor is used for high-frequency applications. There is no comparison between the two capacitors in terms of their performance. Moreover, if you want to know more about Polyester vs Polypropylene Capacitors, then you can ask in the comment section. Thank You!

Related Articles

Inductor vs Resistor: What’s the Differences?

Understanding Coupled Inductors: Operations and Practical Applications

CBC3225T102KR Inductors: Features, Specifications, and Datasheet