Blank PCB and Parts Guide: Types, Applications & Component Selection

Introduction

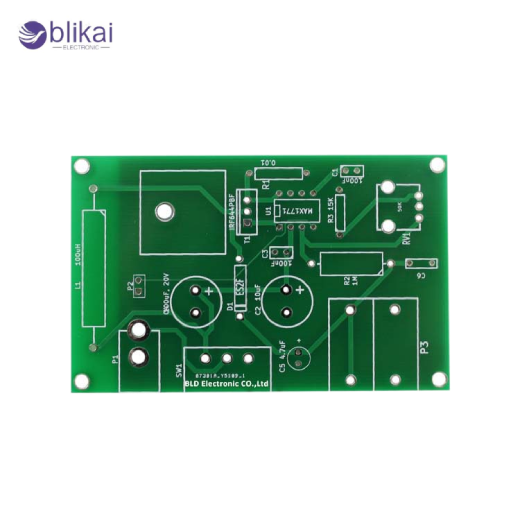

A blank PCB, also known as a bare printed circuit board, is the physical foundation of nearly every electronic device. The circuit layout, electrical performance, mechanical strength and long-term performance of the end product are determined before the components are mounted and soldered to the blank PCB. Since it is as easy as DIY electronics or as complex as industrial automation, selecting the appropriate blank PCB and parts is a crucial step that has a direct impact on cost, level of functionality, and manufacturability.

What Is a Blank PCB?

A blank PCB is a printed circuit board without any electronic components installed. It is made up of an insulating substrate of copper layers which coil up to form conductive paths, pads and planes. These copper patterns are created through etching, milling, or other fabrication processes and serve as predefined locations for soldering electronic components.

Blank PCBs are different from assembled PCBs, which already have components mounted using through-hole or surface-mount technology. They are also distinct from breadboards or perfboards, as blank PCBs typically follow a specific circuit design rather than providing generic connection points. In electronics manufacturing, blank PCBs represent the transition point between circuit design and physical hardware realization.

Common Types of Blank PCBs

Single-Sided Blank PCBs

Single-sided blank PCBs have copper traces on only one side of the substrate. Their PCB is the easiest and cheapest to use, thus suitable for simple circuits, educational projects and low-density designs. Due to the constraints of routing space to a single layer, the complexity of the circuit is relatively small, yet assembly and troubleshooting are simple.

Double-Sided Blank PCBs

The PCBs are in the form of a blanket, where both sides of the board are filled with copper, and both are joined together with plated through-holes or vias. It is a structure that permits high component density and more intricate routing than single-sided boards. PCBs are popular with double-sided applications used in consumer electronics, power supplies, and industrial control systems with a moderate level of complexity and cost-effectiveness.

Multilayer Blank PCBs

Multilayer blank PCB Multilayer blank PCBs have three or more copper layers laminated with insulating material. Power distribution and ground planes are often done in internal layers to enhance signal integrity and minimize electromagnetic interference. These PCBs are needed where high-speed digital circuits are required, compact devices, and where the exact impedance is required.

Flexible and Rigid-Flex Blank PCBs

Flexible blank PCBs are made from bendable substrates such as polyimide, allowing circuits to conform to tight spaces or move during operation. The Rigid-flex PCBs will be a combination of rigid and flexible interconnects, which will have fewer connectors and cables. The designs are typically used in medical devices, aerospace electronics and miniature consumer goods.

Blank PCB Materials and Substrates

FR-4 Blank PCBs

FR-4 is the most commonly used PCB material, and this is a woven fiberglass fabric with epoxy resin. It has a high mechanical strength, electrical insulation, and thermal stability at a reasonable cost. FR-4 blank PCBs are suitable for most general-purpose electronics, including controllers, power modules, and IoT devices.

Aluminum and Metal Core PCBs

Metal core PCBs use an aluminum or copper base layer to improve heat dissipation. This type of blank PCB is especially ideal with components that produce high power, including LEDs, motor drivers and voltage regulators. Metal core PCBs enhance reliability and durability by effectively transferring heat off the components.

Ceramic and High-Frequency PCB Materials

RF, microwave, and high-speed digital Ceramic substrates and high-speed digital special laminates. They are characterized by low dielectric loss, constant permittivity and high thermal performance. These materials are required in antennas, RF modules and exact communication systems, though they are very expensive.

Common Parts Used on Blank PCBs

Passive Components

Resistors, capacitors and inductors are passive components that regulate the voltage, current, filtering, and energy storing. In choosing passive components to be used in a blank PCB, considerations should be made on power rating, tolerance, temperature coefficient, and package size to ensure that they are compatible and stable over time.

Active Components

Active elements like integrated circuits, transistors, diodes, and voltage regulators are used to carry out amplification, switching, control and signal processes. Designers have to align component packages with PCB footprints, and must consider such parameters as operating voltage, current-carrying capability, and thermal needs.

Electromechanical Components

Electromechanical components are connectors, switches, relays, as well as terminal blocks. These are physical interface components between the PCB and the external systems. Factors such as mechanical strength, reliability in contacts, and environmental resistance are also quite important in selecting these parts to use in blank PCB assembly.

How Blank PCBs Are Used in Electronics

Prototyping and PCB Testing

Blank PCBs are widely used in prototyping to validate circuit designs before mass production. Compared to breadboards, they provide better electrical performance and more realistic testing conditions. Engineers and students often use blank PCBs to evaluate signal integrity, power distribution, and thermal behavior.

Low-Volume and Custom PCB Assembly

Blank PCBs can be used to provide a flexible assembly without the setup expenses of large capacity production in cases of small production runs or custom equipment. This is typical of industrial automation, laboratory instruments and special-purpose control systems.

Repair, Modification, and Learning Projects

Blank PCB can also be used for repair or educational purposes. Technicians would know how to recreate damaged circuits, and learners would receive hands-on experience in soldering, layout planning and component selection.

How to Choose the Right Blank PCB and Parts

Electrical and Mechanical Requirements

Defining electrical parameters, which include voltage, current, frequency, and power dissipation, is a step towards selection. Physical factors such as the thickness of the board, size, drilling holes and surrounding temperature conditions, such as vibration or humidity, should be considered.

Component Compatibility and Footprints

Each of the chosen components has to conform to the pad layout and the spacing of the PCB. Standardized footprints minimize assembly mistakes and make sources easier. Component substitutions should also be taken into account by the designers to prevent redesign.

Cost, Availability, and Scalability

PCB material, the number of layers, and the complexity of manufacturing have an effect on cost. Early evaluation of component availability and scalability between prototype and mass production should be performed to avoid problems in the supply chain.

Blank PCB vs Pre-Assembled PCB: Key Differences

The blank PCB can be the most flexible and customizable, as the designer can select and install components as required. Ready-built PCBs are time- and labor-saving and restrictive in design modification. This depends on the complexity of the project, budget, quantity to be produced and the expertise needed.

Common Mistakes When Using Blank PCBs

Incorrect spacing between components is one such error, and it may result in problems with soldering or electrical shortage. The layout planning can result in noise, overheating or signal integrity issues. Ignoring thermal management and EMI considerations often results in unreliable operation, especially in power and high-speed circuits.

FAQ

How do you choose the right blank PCB material?

The PCB right blank material varies according to voltage, frequency, thermal load and environment. FR-4 has been used to suit general electronics, metal-core boards have been used to enhance the heat dissipation performance, and ceramic materials have been used to facilitate RF performance.

How important is PCB thickness in blank PCB design?

PCB thickness affects mechanical strength, impedance control, and heat dissipation. The boards that are thicker are firmer and have the others that are lighter and fit in the small shapes.

Does surface finish matter on a blank PCB?

Yes, surface finish directly affects solderability and shelf life. The most popular finishes, such as HASL, ENIG and OSP, are determined according to assembly method and reliability.

How are vias planned on a blank PCB?

The vias will be designed depending on the routing density, current carrying capacity, and EMI. Via size, spacing, and quality of plating play a critical role in multilayer and high-speed designs.

When should component availability be considered in blank PCB projects?

The design phase should take into consideration the availability of components so that redesigns and supply chain problems can be avoided. Choosing standard packages and second-source parts improves scalability.

Some images are sourced online. Please contact us for removal if any copyright concerns arise.

What is the Circuit Symbol for a Multimeter? (Guide)

7408 Integrated Circuit: Key Features & Applications in Electronics

What Is a Short Circuit? Causes, Effects, and Prevention

Circuit Board Repair: Guide for Beginners

Types of Circuit Breakers: Overview and Applications

Discrete Circuit vs Integrated Circuits: What's the Differences?

Microprocessor vs Integrated Circuit:Which One Is Better

What is an Integrated Circuit (IC)? Working, and Types (Guide)

Applications of Circuit Protection: Everything Explained

Isolator vs Circuit Breaker: What's the Differences?