Temperature Sensor Selection: Types & Design Techniques Analysis

Do you understand how various sensors commonly found in life work? The Sensor Encyclopedia is now available online, guiding you through the fundamentals to mastery of a wide range of commonly used sensors and their applications.

Today, let's start with temperature sensors — temperature sensors are devices used to measure the temperature of the environment or objects. They play an important role in various applications, from household appliances to industrial control systems. They find extensive application in devices like water heaters, clothes dryers, heating, ventilation, and air conditioning (HVAC) systems, microwave ovens, and more. They are also used in industrial production to monitor various equipment and instruments in real-time. Their applications are quite extensive.

Temperature sensors come in various types with different characteristics.

There is a wide variety of temperature sensors, each with its own operating principles and characteristics. Below is an overview of several typical temperature sensors, outlining their roles, attributes, and operational principles.

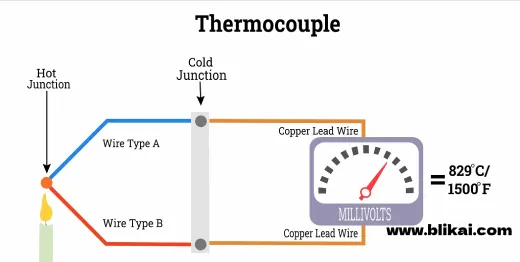

Thermocouple

A thermocouple comprises a circuit of two dissimilar.A thermistor is a unique form of resistor that exhibits alterations in resistance in response to temperature variations. metal or alloy wires. When the junction of the two wires experiences a temperature change, it generates an electromotive force (EMF). There is a certain relationship between the generated voltage and the temperature change, which can be measured to determine the temperature. Thermocouples can withstand extreme temperature ranges, from very low to extremely high temperatures, making them very useful in various industrial applications. They demonstrate heightened sensitivity and can promptly react to fluctuations in temperature, rendering them appropriate for tasks necessitating immediate adjustments. The relationship between the output voltage of a thermocouple and temperature is typically linear, allowing simple circuits to interpret and measure temperature. Since thermocouples are predominantly composed of metal or alloy materials, they possess a degree of resistance against certain corrosive gases and liquids. They can typically withstand certain pressures, making them suitable for environments requiring pressure resistance, such as high-pressure furnaces. There are various types of thermocouples with different characteristics. Compared to some other high-temperature measurement techniques, thermocouples have relatively low manufacturing costs, making them an economically practical temperature sensing solution. Since the output of thermocouples is a voltage signal, temperature measurement can be conducted over long distances, which is advantageous in applications requiring temperature measurement at remote locations.

Thermistor

A thermistor is a particular kind of resistor that undergoes changes in resistance as the temperature fluctuates. Typically, the resistance of a thermistor decreases with increasing temperature or increases with increasing temperature, depending on the material of the thermistor. Generally, when the temperature rises, the resistance of a thermistor decreases (NTC - negative temperature coefficient), or in some cases, the resistance of a thermistor increases with temperature (PTC - positive temperature coefficient). Additionally, thermistors are highly sensitive to temperature changes, making them particularly useful in applications requiring high sensitivity, such as precise temperature measurement and control. The resistance-temperature characteristics of some thermistors are linear, meaning that resistance varies linearly with temperature, while others are nonlinear, with more complex resistance-temperature curves. Thermistors can be used over a wide temperature range, from very low to very high temperatures, depending on the thermistor material selected. They demonstrate relatively quick response rates, facilitating immediate reaction to temperature variations, rendering them appropriate for tasks necessitating real-time regulation. Various thermistor materials and fabrication techniques can tailor their performance to specific temperature ranges, precision levels, and sensitivity. Thermistors are usually produced as compact, uncomplicated components, rendering them cost-effective and space-efficient for diverse applications. The majority of thermistors consume minimal power during use, rendering them highly practical in numerous battery-operated scenarios.

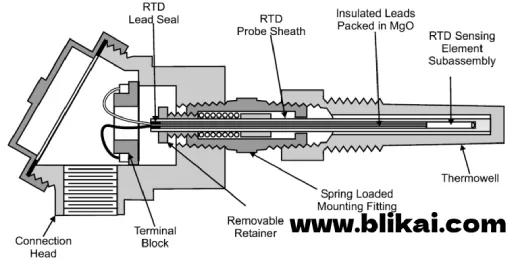

Resistance Temperature Detector (RTD)

A Resistance Temperature Detector (RTD) is a device that exhibits a resistance change in response to temperature variations, operating on the principle that the resistance of a material shifts with temperature. Unlike thermistors, an RTD's resistance alteration is directly proportional to temperature changes. Frequently utilized materials encompass platinum, nickel, and copper, with platinum RTDs being the most prevalent.

Within a relatively small temperature range, the resistance of an RTD typically exhibits a linear relationship with temperature, making temperature measurement and calibration relatively straightforward. RTDs generally offer high measurement accuracy, especially within relatively narrow temperature ranges, making them very useful in applications requiring high precision.

RTDs offer stable resistance values, exhibiting minimal susceptibility to fluctuations over time and operating conditions, thereby bolstering sensor reliability. Various materials used in thermal resistors enable adaptation to diverse temperature ranges, spanning from extremely low to exceedingly high temperatures, to address a wide array of application needs.

RTDs typically have small temperature drift, meaning they exhibit high measurement stability at different temperatures. They typically don't necessitate supplementary heating elements, leading to relatively low power consumption, making them well-suited for prolonged operation and energy-efficient applications. The temperature-resistance characteristics of RTDs are generally stable, facilitating calibration to ensure measurement accuracy. RTDs are relatively unaffected by external environmental factors such as humidity and pressure.

Temperature Sensor IC (Integrated Circuit):

Temperature Sensor ICs are typically integrated circuit devices that convert temperature into voltage or digital signals. These sensors are widely used in various electronic devices and industrial applications. Temperature Sensor ICs generally offer high temperature measurement accuracy, meeting the requirements of applications demanding precision. The majority of Temperature Sensor ICs offer digital output, facilitating direct connection to microcontrollers, microprocessors, or other digital electronic systems. These sensors are often highly integrated devices, incorporating sensor elements, signal processing circuits, and communication interfaces, saving costs and space in system design. Numerous Temperature Sensor ICs feature relatively low power consumption, rendering them suitable for battery-powered or energy-efficient applications. These sensors can cover a wide temperature range, including indoor temperature, low temperature, high temperature, etc., meeting various application needs. Some Temperature Sensor ICs incorporate calibration and compensation circuits internally, improving their performance stability under different conditions. Most Temperature Sensor ICs support standard digital communication interfaces, such as I2C, SPI, making connection to other digital devices more convenient. Since Temperature Sensor ICs typically support internal processing and calibration, they are user-friendly and do not require complex external circuits.

Infrared Temperature Sensor

The Infrared Temperature Sensor is a non-contact temperature sensing technology that measures the surface temperature of objects without direct contact, by detecting the infrared radiation emitted by the object. They detect the infrared radiation emitted by objects and convert it into temperature data. This sensor is commonly employed for remote and contactless temperature measurement. Infrared Temperature Sensors usually have a fast response time, providing real-time temperature data in a short period. They adapt to the radiation characteristics of different object surfaces and are not affected by the material of the object surface, making them suitable for various objects. They boast an extensive temperature range, spanning from extremely low to exceedingly high temperatures, while delivering precise measurements. Infrared Temperature Sensors are not affected by external environmental factors such as light and humidity, making them suitable for special environments such as high radiation, dusty, or humid conditions. Because Infrared Temperature Sensors operate without physical contact, they can gauge temperature from a distance, a capability valuable for scenarios demanding temperature oversight in distant locales. They can be situated in inaccessible areas and observed remotely through either wireless or wired connections.

Selection and Design Techniques for Temperature Sensors

Different types of sensors operate based on various principles, but generally, they can be categorized as materials or principles sensitive to temperature changes. They measure the changes in these materials or principles and convert them into electrical signals or other forms of output to represent temperature changes. Selecting the appropriate temperature sensor depends on the application requirements, such as accuracy, sensitivity, response time, temperature range, etc.

When using temperature sensors in applications, design techniques are crucial to ensure the system can accurately and stably measure temperature. When designing a system, first, choose the appropriate type of temperature sensor based on the application requirements and environmental conditions, such as thermistors, thermocouples, infrared sensors, etc. Next, evaluate the system's temperature measurement accuracy and resolution needs, and choose the appropriate sensor accordingly. Keep in mind that higher accuracy often entails using more costly sensors.

Calibration procedures should be implemented before using temperature sensors to ensure the consistency between the sensor's output and the actual temperature. Calibration should be performed regularly, especially after prolonged sensor usage or changes in environmental conditions. It's essential to consider methods for preventing electromagnetic interference to ensure the sensor's output remains unaffected by external electromagnetic fields. This can involve implementing shielding materials or maintaining a safe distance from electromagnetic sources.

Additionally, consider the sensor's operating environment, including factors such as temperature range, humidity, pressure, etc., to ensure that the selected sensor can operate correctly in the expected environment. Also, consider the sensor's power supply requirements and power consumption, especially in cases requiring long-term operation or battery-powered applications. Reasonable power management helps extend the system's operating time.

Incorporate protective measures into the design to safeguard the sensor against potential damage from factors such as overvoltage, overcurrent, or electrostatic discharge. In situations where temperature changes may affect the sensor, consider using temperature compensation techniques to improve the accuracy of temperature sensors.

Take into account the handling and transmission of sensor data in the design, which may involve utilizing microcontrollers, data processing algorithms, and communication protocols. Ensure proper installation and placement of sensors to guarantee accurate temperature measurement, avoiding locations where external heat or cold sources may influence readings. Implementing these techniques will contribute to the reliable performance of temperature sensors in various applications.

Common Issues and Solutions with Temperature Sensors

When employing temperature sensors in design, you may encounter common issues such as calibration and accuracy problems. Manufacturing disparities or drift over extended use can impact the sensor's output, necessitating regular calibration. Known temperature reference points can be used for adjustment. Moreover, opt for sensors with higher accuracy and utilize multipoint calibration when necessary.

Electromagnetic interference is also a common issue in design; external electromagnetic fields may affect the sensor's output, leading to inaccurate temperature measurements. In such cases, use shielding materials, stay away from potential electromagnetic fields, or use differential input designs to reduce the impact of electromagnetic interference.

Furthermore, environmental conditions may influence the performance of temperature sensors. Extreme conditions like high temperature, low temperature, high humidity, and others may affect the sensor's accuracy and reliability. Choose sensors that meet the application requirements and ensure the sensors can adapt to the expected environmental conditions.If required, utilize measures such as protective covers, heating elements, or cooling mechanisms to uphold the sensor's optimal operating conditions.

The elevated power consumption of sensors could impact the system's power management, particularly in battery-powered scenarios.Solutions include selecting low-power sensors for low-power applications and implementing effective power management strategies such as sleep modes, dynamic power adjustment, etc.

On the other hand, some sensors may exhibit nonlinearity or drift under extreme temperature conditions. Ensure appropriate temperature calibration is performed within the sensor's linear range, and if feasible, opt for sensors with minimal temperature drift. Improper sensor placement may also be affected by external heat sources or cold sources. Ensure that the sensor's installation location is appropriate and away from potential sources that may affect its performance.

Temperature sensors also necessitate data processing and communication, which might introduce errors, potentially resulting in inaccurate temperature readings. Therefore, use reliable data processing algorithms and ensure the use of accurate communication protocols to ensure the reliability of sensor data.

| Types | Application Characteristics |

| Thermocouple | Thermocouples are temperature sensors extensively utilized in high-temperature and extreme environments, rendering them suitable for diverse industrial and scientific applications. |

| Thermistor | Thermistors are cost-effective and extensively employed temperature sensors, renowned for their heightened sensitivity, affordability, and adaptability to a wide range of application needs. |

| Resistance Temperature Detector (RTD) | RTDs, distinguished by their precision, stability, and versatile applicability, have emerged as prevalent sensors in industrial control and temperature monitoring tasks. |

| Integrated Circuit Temperature Sensor (IC) | Integrated circuit (IC) temperature sensors provide benefits in terms of accuracy, integration, and energy efficiency, establishing them as prevalent solutions for temperature sensing across various electronic products and industrial settings. |

| Infrared temperature sensors | Infrared temperature sensors, characterized by their non-contact operation, swift response, versatile adaptability, and suitability for diverse temperature ranges, find widespread applications across numerous industries and use cases. |

Conclusion

The issues and solutions discussed regarding temperature sensors in this article provide some recommendations for using temperature sensors. However, specific solutions may vary depending on the specific application and type of sensor. It is essential to take into account various factors such as environmental conditions, power consumption, accuracy requirements, and so on. This holistic approach will help ensure the correct operation of temperature sensing systems.

Related Articles

Flexible Sensor Complete Guide

Intelligent Sensors: Definition, Configurations, and Utilizations

Comprehensive Guide to Common Sensors