What is the DRV8825 Stepper Motor Driver? A Detailed Description

What is the DRV8825 Stepper Motor Driver?

The DRV8825 is a motor driver used in printers, scanners, and other automated hardware applications. It is particularly made for stepper motors. It has a microstepping indexer, two H-bridge drivers, and the capacity to run bipolar stepper motors with a 2.5 A per-coil output current. Stepper motors with DRV8825 ratings can be used to drive motors within a broad voltage range of 8.2 V to 45 V.

Features about the DRV8825 Stepper Motor Driver

- PWM-controlled microstepping motor driver

- Integrated indexer for precise movement

- Up to 1/32 microstep support

- Various attenuation modes: mixed, slow, and rapid decay

- Wide operating supply voltage range: 8.2V to 45V

- 2.5A maximum drive current at 24V, TA = 25°C

- Simple STEP/DIR interface

- Low-current sleep mode for power saving

- Built-in 3.3V reference output

- Compact package design

- Protection features: OCP, TSD, UVLO, nFAULT

Technical Specifications of the DRV8825 Stepper Motor Driver

|

Operating Voltage (VMOT) |

8V to 45V |

|

Logic Voltage (VDD) |

3.3V to 5.5V |

|

Step Modes |

Full-step, Half-step, 1/4-step, 1/8-step, 1/16-step, 1/32-step |

|

Operating Temperature Range |

-20°C to 85°C |

|

Dimensions |

9.7mm x 16.2mm |

|

Package Type |

Surface Mount (TSSOP-28) |

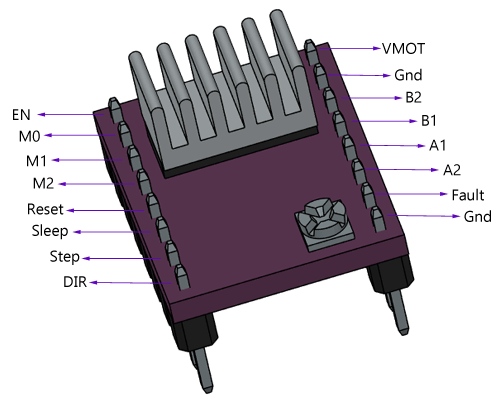

Pin Configuration of the DRV8825 Stepper Motor Driver(DRV8825 datasheet)

|

Pin Name |

Description |

|

VDD & GND |

Connected to 5V and GND of Controller |

|

VMOT & GND MOT |

Used to power the motor |

|

B1, B2 & A1, A2 |

Output Pins, Connected to the 4 Wires of motor |

|

DIRECTION |

Motor Direction Control pin |

|

STEP |

Steps Control Pin |

|

M0, M1, M2 |

Microstep Selection Pins |

|

FAULT |

Fault Detection Pin |

|

SLEEP |

Pins For Controlling Power States |

Applications of DRV8825 Stepper Motor Driver

printer

Scanners

Robotics

Game consoles

Automated Teller Machines

Currency Processors

Video Security Cameras

Office automation equipment

Factory Automation

How does DRV8825 stepper motor driver work?

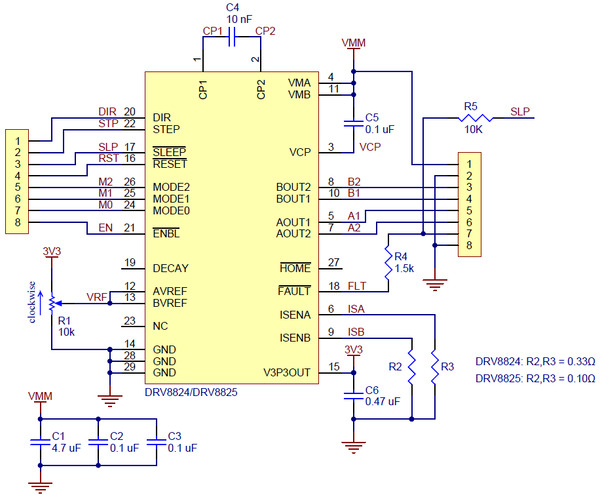

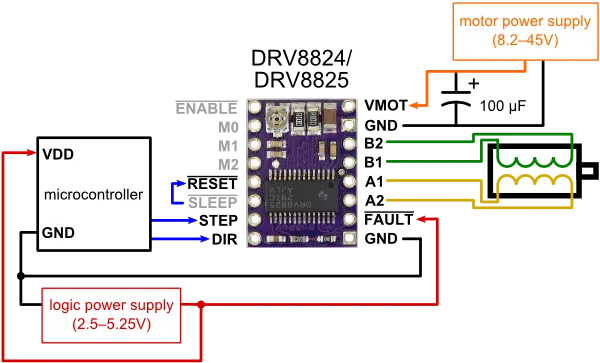

The stepper motor can be controlled using only a few pins on the DRV8825. The pinout and interface of the A4988 stepper motor driver bay is essentially the same as that of the module. Below is the DRV8825 diagram

Stepper motors are precisely controlled by the DRV8825 stepper motor driver through the translation of sophisticated signals from a microcontroller. This is a summary of how it operates:

Microstepping is supported by the DRV8825, allowing for more accurate and smoother movement. It accomplishes this by isolating each full step of the motor into littler increments, enabling better control over the motor's position.

Current Regulation: The driver regulates the current flowing through the motor coils to anticipate overheating and guarantee ideal execution. To regulate the direction and amount of current flowing through the motor windings, it makes use of an intertwined H- bridge configuration.

PWM Control:The driver is operated by the microcontroller's Pulse Width Modulation( PWM) signals. The driver modifies the voltage supplied to the motor, hence managing the necklace and speed of the motor, by changing the obligation cycle of these signals.

Step Generation: The driver generates step pulses based on the input signals gotten from the microcontroller. These step pulses decide the course and separate the motor moves, permitting for exact situating and movement control.

Protection Features: The DRV8825 includes different security features to defend against overcurrent, overtemperature, and voltage spikes. These features help anticipate damage to the motor and driver, guaranteeing reliable operation under different conditions.

Case Studies with DRV8825

3D Printer Upgrade: An individual passionate about 3D printing as a hobby aimed to enhance their printer's performance. Through the substitution of the factory-installed stepper motor drivers with DRV8825 modules, they achieved a more refined and quieter operation, leading to improved print quality and minimized artifacts. The ability to adjust microstepping on the DRV8825 allowed for precise calibration of print resolution, ultimately elevating the overall printing accuracy.

CNC Router Retrofit: A modest woodworking shop aimed to enhance the accuracy and dependability of their CNC router. By incorporating DRV8825 drivers into the control system, they achieved improved motion control and minimized vibrations during cutting tasks. The inclusion of overcurrent protection effectively prevented motor damage in the event of tool jams, guaranteeing uninterrupted production.

Robotics Platform Development: DRV8825 drivers were readily integrated into the design of the university robotics team robot because of its compact size and compatibility with various microcontrollers. These drivers were used in the robot's motor control system. Precise movement and positioning are necessary for navigation and manipulation activities, and the DRV8825's precise current control and microstepping characteristics made this possible for the robot.

FAQs of DRV8825

1. What is DRV8825?

The DRV8825 is a broadly applied module for driving stepper motors in operations similar as 3D printers, CNC machines, and other movement control systems. This module enables exact control of stepper motors, guaranteeing exact and harmonious motion.

2. How does DRV8825 work?

The DRV8825 capacities by controlling the stream of current to the stepper motor coils. It applies a method known as microstepping to accomplish higher exactness and more consistent development in comparison to utilizing full-step driving techniques.

3. What are the key features of DRV8825?

With its malleable current operation, thermal arrestment prevention, overcurrent protection, support for microstepping of over to1/32 step determination, and compatibility with a variety of microcontrollers and motion control platforms, the DRV8825 is a protean device.

4. What is the maximum current rating of DRV8825?

The maximum current rating of DRV8825 varies based on the particular demonstrate and operating variables. Regularly, it has the capacity to oversee streams of up to 2.5A per stage when appropriately heatsinked. However, for ideal execution, it is significant to refer to the datasheet and follow the suggested operational instructions.

5. What are the typical applications of DRV8825?

The DRV8825 is broadly utilized in a assortment of applications that require exact administration of stepper motors, including 3D printers, CNC machines, camera sliders, linear actuators, and robotized systems. Its flexibility, effectiveness, and user-friendly nature have set up it as a sought-after choice for both enthusiasts and experts.

6. Where Can I Find More Information about DRV8825?

You can access further details about DRV8825, such as datasheets, application notes, and design resources, from the Texas Instruments or blikai website, as well as through multiple online forums and communities focused on stepper motor control and electronics projects.

Final Thoughts on DRV8825

Because of its great performance and adaptability, the DRV8825 stepper motor driver is a well- liked option for a range of motion control operations. It offers reliable and effective motor control with features like thermal shutdown, configurable microstepping, and overcurrent safety. Its compact size and wide voltage range further enhance its usability. Whether in 3D printers, CNC machines, or robotics, the DRV8825 stands as a dependable solution for precise and smooth motion.