How to Test a Capacitor: Simple Steps and Tools

What are Capacitors?

Basic passive electronic components that store and release electrical energy are called capacitors. In electronic circuits, capacitors are frequently used for filtering, energy storage, coupling, isolation, and regulation.

Function of Capacitors

1. Energy Storage: In order to store and release electrical energy, capacitors can be connected to a power source. This point is helpful for reducing voltage oscillations and stabilizing the power force in a circuit.

2. Filtering: In order to remove uninvited ripple and noise from signals, capacitors are constantly employed in filtering operations, similar as power force. This results in a cleaner output.

3. Coupling and Decoupling: Capacitors have the ability to conduct AC signals while obstructing DC components. This function is used in signal coupling between different stages of a circuit. Also, insulation capacitors are employed to keep unwanted hindrance at bay by keeping the voltage position steady.

4. Timing and Oscillation: When coupled with resistors or inductors, capacitors can produce RC( resistor- capacitor) or LC( inductor- capacitor) circuits. Time delays are produced by these circuits, which are essential. Applications like oscillators and timers require the ability to create oscillations or manage scheduling functions.

5. Power Factor Correction: In AC power systems, capacitors are employed to acclimate the power factor. By lowering reactive power and barring system losses, it increases effectiveness.

6. Signal Smoothing: Digital circuits employ capacitors to mitigate abrupt voltage dips and surges. This guarantees error-free, power fluctuation-free circuit operation.

7. Energy Discharge: When required, capacitors can instantly release stored energy. They are employed in pulsed lasers and camera flashes, among other things. or pacemakers that are electric.

Key Properties of Capacitors

- Capacitance (C): The capacity of a capacitor to store electricity.

- Voltage Rating: The highest voltage that a capacitor can tolerate before failing.

- Equivalent Series Resistance (ESR): Heat product and energy loss in capacitors are caused by internal resistance.

- Temperature Coefficient: Demonstrates the temperature variation of the capacitor.

- Leakage Current: The bitsy quantum of current that charges a capacitor by flowing through a captain.

Types of Capacitors

Ceramic Capacitors: Ceramic capacitors are famed for being reliable and stable. Usually, high frequency applications employ it. Ceramic accoutrements are used to make ceramic capacitors, which come in two primary kinds multilayer and single- subcaste. MLCCs, or multilayer ceramic capacitors, give large capacity in a compact design. They are hence perfect for little electronics.

Electrolytic Capacitors: Electrolytes are used in these capacitors to produce high capacitance. There's opposition in these capacitors. This implies that they've to be duly linked to the circuit. Due to their large capacity and affordable price, electrolytic capacitors are constantly employed in energy storehouse and power filters.

Tantalum Capacitors: Tantalum capacitors are famed for their stability and responsibility and for having a large capacity in a little package. It can also be employed in operations like perfection electronics and medical outfit that need harmonious performance over a broad temperature range because of its polarization features.

Film Capacitors: Plastic film is used in the production of film capacitors as an electrical insulator. offers low losses and steady electrical performance. Because they'renon-polarized, film capacitors are constantly employed in power force and signal processing operations that need a high degree of delicacy and responsibility.

Supercapacitors: Supercapacitors, another name for ultracapacitors, are capacitors with far advanced capacitance values than regular capacitors. In systems like memory backup and regenerative retardation that demand a quick power source, ultracapacitors are employed to store energy.

Aluminum Organic Capacitors: These capacitors combine the characteristics of organic composites with aluminum electrolytic capacitors. As a result, effectiveness and environmental impact are balanced. These ultracapacitors are typically utilized in the automobile sector and other fields where dependability and toughness are essential.

Key Considerations for Selection

When choosing a capacitor for a specific application, consider the following factors:

- Required capacitance and tolerance.

- Voltage rating.

- Physical size and form factor.

- Temperature stability.

- Equivalent Series Resistance (ESR).

- Operation-specific conditions( e.g., high- frequence performance, life, etc.).

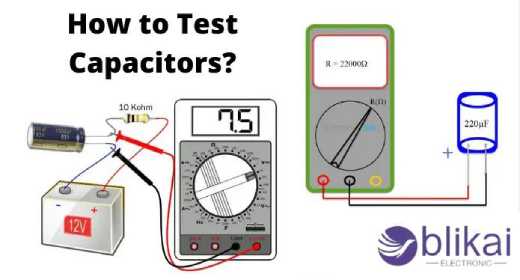

Tools Needed for Testing Capacitors

1. Digital Multimeter (DMM): Numerous DMMs have a capacitance dimension function, allowing you to measure the capacitance of a capacitor directly. This is one of the most common tools for introductory testing.

2. LCR Meter: This tool provides more precise measures of capacitance, inductance, and resistance. It's especially useful for high- perfection measures and for testing capacitors with veritably low or veritably high capacitance values.

3. Capacitor Tester:Testers with technical functions for measuring capacitance. Typically, they can measure ESR (Equivalent Series Resistance) among other things.

4. ESR Meter: This instrument calculates a capacitor's equivalent series resistance. This is helpful in determining a capacitor's health. This is especially true for older capacitors, since they age and develop an increased ESR.

Safety Precautions Before Testing

It's crucial to follow safety guidelines when testing a capacitor in order to avoid mishaps and get precise results:

1. Discharge the Capacitor: Even after being removed from the circuit, capacitors hold their charge. To safely discharge a capacitor before testing, use a resistor (usually 10kΩ or 1W). Shorting the leads directly can be dangerous and cause sparks or damage.

2. Wear Protective Gear: Put on safety spectacles to shield your eyes from implicit detriment or capacitor discharge. Wearing an ESD wrist swatch is a smart idea because electrostatic discharge( ESD) can harm delicate factors.

3. Check for Physical Damage: Look for any suggestions of damage, similar as swelling, oohing, or erosion, on the capacitors. Damaged capacitors have the eventuality to explode or unmask sharp accoutrements , which can be deadly.

4. Verify Correct Meter Settings: Make that the capacitance measurement mode on the multimeter or tester is selected correctly. Inaccurate readings or cadence damage could arise from using the wrong settings.

5. Handle with Care: To reduce your chance of entering an electric shock, avoid reaching the capacitor's wires or outstations with your bare hands, especially if it's still charged.

6. Observe Polarization: When measuring capacitors with opposition( like electrolytic capacitors), be sure the opposition is accurate. Reversing the opposition can damage the capacitor and give incorrect readings.

7. Work in a Dry Environment: It's stylish to avoid testing capacitors in damp conditions to lower the threat of electric shock.

8. Follow Manufacturer's Instructions: For details on how to perform tests and specifications for the specific capacitor you're using, always consult the manufacturer's instructions.

Steps to Test a Capacitor

Using a Multimeter with Capacitance Measurement:

1. Turn off Power: Before testing, make sure the circuit is out.

2. Discharge the Capacitor: To safely discharge the capacitor, use a resistor or capacitor discharge tool.

3. Set the Multimeter: Put the multimeter in the mode for measuring capacitance. (frequently used with symbols like "C" or "⎓").

4. Measure the Capacitance: Attach the multimeter inquiry to the leads of the capacitor.(Opposition has no bearing onnon-polarized capacitors. Make sure the terminals of polarized capacitors match. Examine the multimeter's displayed value and contrast it with the capacitor's nominal value.

Using an ESR Meter:

1. Turn off Power and Discharge the Capacitor: As with the multimeter method.

2. Connect the ESR Meter: Attach the ESR meter leads to the capacitor terminals.

3. Read the ESR Value: The meter will display the ESR. Compare this to the typical ESR range for the capacitor's type and rating.

Using a Capacitance Meter or LCR Meter:

1. Prepare the Capacitor: Discharge it and ensure it is out of circuit.

2. Connect the Meter: Follow the same steps as with the multimeter, but these devices might offer more accurate readings or additional features.

Visual Inspection:

Look for Physical Signs: Check for bulging, leaking, or corrosion, which are signs of a bad capacitor. If you find these, the capacitor is likely defective.

In-Circuit Testing:

1. Turn off Power and Discharge: Corroborate that the circuit has beende-energized.

2. Measure Capacitance: There are situations when a circuit's capacitance can be measured. However, the measurement might not be very exact because of the parallel components. if you wish for more precise outcomes. The capacitor may need to have one leg removed.

Safety Note:

Larger capacitors in particular hold their charge even in the event of a power outage. Always discharge capacitors before handling them or testing them to avoid electric shock.

Related Articles

How to Test a Capacitor with a Multimeter [Guide]

Variable Capacitors: A Complete Guide

What Causes Capacitors to Fail