Choose the Right Electrical Connector Types: A Simple Guide

For illustration, fantasize yourself nearing time to wire a critical electrical system and the inviting choice of connectors to elect from. So how do you know which bone is right for your design? opting the wrong connector might result in poor performance, safety issues, or indeed a system failure. It’s a problem that affects both DIY-ers and professional electricians likewise.

This guide will help you understand how electrical connector types come into play. We’ll begin with the fundamentals, cover general-purpose and specialized connectors, and offer guidance on aligning connectors with your requirements.

What are Electrical Connectors?

Electrical connectors are devices that connect together two or further electrical circuits. They're necessary corridors available in different shapes, confines, and arrangements, erected to handle certain electrical specifications and environmental conditions.

Why Choosing the Right Connector Matters

Choosing the Right Electrical Connector opting for the applicable electrical connector is important to the particular safety, effectiveness and trustability of your electrical system. Using the correct connector ensures not only a secure connection, but also protects against implicit troubles like short circuits, overheating, or system malfunctions. Also, the correct connectors used can ameliorate the performance of your electrical set up and protect its life.

Key Factors to Consider When Selecting Connectors

Current and voltage ratings: Choose a connector that can handle the electrical load.

Environmental conditions: Things like temperature, moisture and exposure to chemicals.

Size and space constraints: Space and fit — only select connectors that you will have available space to use.

Durability and longevity: Choose connectors that are able to handle repeated use and exposure to the elements.

Ease of installation and maintenance: Choose a proper insulation level as per the application.

Common Types of Electrical Connectors

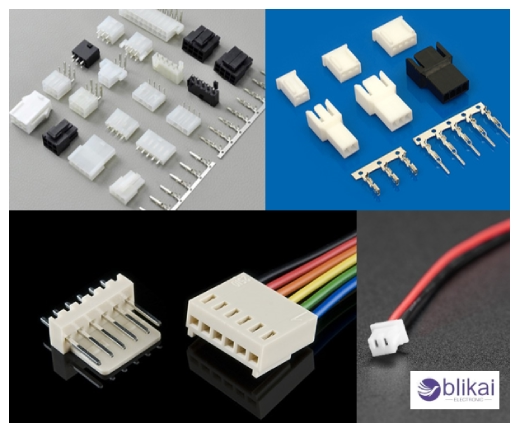

Pin and Socket Connectors

Pin connectors are also a type of electrical connector used in numerous electronics and appliance-type operations. These connectors have a manly part(pins) that's fitted in a womanish part(sockets). They offer secure connections and are often found in computer peripherals, audio equipment, and automotive applications.

Terminal Block Connectors

Terminal Block Connectors — This is a way to connect multiple wires together in a very nice manner. They have a sequence of screw terminals that makes it easy to put and take wires. Often found in the likes of industrial control panels, HVAC systems, and lighting installations, these connectors.

Crimp Connectors

Thus, crimp connectors are made for speed and efficiency when it comes to connecting wires together. They're made up of an essence barrel that's waved onto the wire via a special tool. Their ease of use and durable nature means that crimp connectors are generally used in everything from automotive wiring to appliance repairs to do-it-yourself electrical systems.

Splice Connectors

Splice connectors are used to join two or further wires together. They come in colorful forms, including twist-on wire nuts and heat-shrink butt connectors. These connectors are essential for extending wires or repairing damaged connections in domestic and marketable electrical systems.

IDC (Insulation Displacement Connector)

IDC connectors – sequestration-relegation connectors that do n't require the stripping of wire for each connection These have small sharp essence blades that pierce the wire sequestration and come into contact with the captain. numerous operations are used in telecommunications outfits, as well as in computer networking and some automotive operations.

Specialized Electrical Connectors

Audio and Video Connectors

Audio and videotape connectors play a vital part in high-dedication home theaters, pro audio gear, and videotape product devices. These may include RCA connectors, 3.5 mm audio jacks, professional XLR connectors, or HDMI anchorages. Each of these serves some special purpose from carrying stereo audio signals to allowing simultaneous transmission of high-definition video and audio.

Automotive Connectors

This industry uses specific technical connectors that must last in hostile environments and at low and high temperatures. From simple two-pin connectors for your car's lighting to sophisticated multi-pin connectors for your machine operation systems or infotainment units, these connectors need to reliably connect electrical devices in your vehicle.

Industrial Connectors

Artificial surroundings demand robust and dependable connectors capable of opposing extreme conditions. These connectors are designed to repel humidity, dust, chemicals, and mechanical stress. examples include indirect connectors, heavy-duty blockish connectors, and modular terminal blocks. They are generally used in manufacturing equipment, robotics, and process control systems.

PCB (Printed Circuit Board) Connectors

published circuit boards(PCBs) are one of the most important factors in electronic devices that need to be connected to other circuits. Different types of connectors jut heads, card edge connectors, board-to-board connectors and so on. They're pivotal at every position, from smartphones to artificial control systems, allowing easy modular design and form.

Matching Connectors to Your Application

Assessing your power requirements

The first step in matching connectors to your application is to evaluate your power needs. Consider the voltage and current requirements of your system. High-power applications may require connectors with larger contacts and more robust insulation, while low-power devices can use smaller, simpler connectors.

Considering environmental factors

Global environmental conditions are a big aspect in determining the right connector. For out-of-door or artificial operations, you need connectors designed to survive exposure to humidity, dust, or extreme temperatures. select connectors with a suitable IP(Ingress Protection) standing that can repel your operation-specific environmental stresses.

Evaluating space constraints

Space limitations can greatly influence your connector choice. In compact devices or tight spaces, miniature or low-profile connectors may be necessary. Conversely, larger equipment may accommodate bigger, more robust connector types. Always consider the available space and any potential interference with other components when selecting a connector.

Determining required durability

Finally, assess the expected lifespan and usage frequency of your connection. Applications that require frequent connecting and disconnecting will need connectors designed for multiple mating cycles. For permanent or rarely accessed connections, simpler and more cost-effective options may suffice.

Installation and Maintenance Tips

Proper connector installation techniques

When installing electrical connectors, perfection is crucial. The first thing you need to do is to turn off the power and make sure the area is clean and dry. For crimp-style connectors, use the correct releasing tool and crimp with indeed pressure. When soldering connections, clean the shells completely and use the proper quantum of solder. For quick-connect terminals, ensure a snug fit without over-tightening.

Tools needed for different connector types

Each connector type requires specific tools. For crimp connectors, invest in a quality crimping tool with various die sizes. Soldered connections need a soldering iron, solder, and flux. For screw terminals, use insulated screwdrivers of the correct size. Wire strippers are essential for all connections, while multimeters help verify proper installation.

Maintenance practices for longevity

Regular maintenance extends connector life. Inspect connections periodically for signs of corrosion, looseness, or heat damage. Clean connections with contact cleaner and a soft brush. In high-vibration environments, check and re-tighten connections as needed. Apply dielectric grease to protect against moisture and corrosion in outdoor or high-humidity settings.

Troubleshooting common connector issues

Common issues include loose connections, corrosion, and improper crimping. If you encounter intermittent power, check for loose connections and tighten as necessary. Corrosion often appears as green or white buildup; clean affected areas and consider replacing severely corroded connectors. For faulty crimps, cut the wire back and re-crimp using the correct tool and technique.

Safety Considerations

Importance of proper insulation

Insulation is an important part of electrical connectors to prevent any kind of electrical failure. Properly insulated connectors prevent electric shocks, short circuits and fire. They also ensure that the electrical connection stays intact by keeping moisture or impurities away.

Avoiding overheating and fire hazards

Electrical connectors being affected on the grounds of risking overheating has been the cause of some serious fires. To reduce this risk, it is important to select the connectors that are rated for appropriate application levels of current and voltage. Checking for wear, loose connections, or darkening regularly can help detect potential overheating issues before they become dangerous.

Compliance with electrical codes and standards

Complying with electrical codes and standards is not only a mushy necessity, however it is a very important safety measure. These laws were put into place to help keep the installation and operation of electrical systems safe. Consult relevant local and national electrical codes when selecting and installing connectors. Compliance helps avoid dangerous situations (such as accidents or injuries), keeps you out of a lawsuit, and keeps your electrical set-ups in good shape for life.

Conclusion

Choosing the right electrical connector is essential to make sure that your electrical connections are both safe, effective and dependable in any of your systems. Whether it's terminal blocks or banana entrapments or connectors for automotive operations or artificial connectors you have the knowledge and access to data that will help you make the right decision. However, these connectors do not only have to meet present volt requirements; they must also take into account environmental conditions such as humidity and heat, as well as future environments if more connectors need to be added in the future.

Just bear in mind that so much of how long your electrical connections can last lies in how well they are installed in the first place, and how regular maintenance is performed on them. Follow the guidance of manufacturers and the standards of the industry, and just stay safe. Hopefully, you now have a solid groundwork of the principles and tips you can use to choose, install, and maintain the right electrical connectors for your applications and keep your electrical systems running strong for years to come.

Related Articles

Electrical Isolator: Types, Working and Applications (Guide)

Varieties of Electrical Wires and Cables

How to Replace a Broken 9V Battery Connector

What is a DB9 Connector? (Everything Explained)

Mastering RJ45 Connectors: A Comprehensive Handbook

What do Microminiature and Ultraminiature RF connectors entail?

What is an Integrated Circuit? Applications, Functions and Types (Guide)

What is an Integrated Circuit?

What is Hartley Oscillator: Circuit, Working, and its Applications

556 Timer Circuits: Features, Specification and Applications

Integrated circuit chip: Types, Applications, and FAQ

Microprocessor Vs Integrated Circuit: What’s the Differences?

Varistors: How Do They Safeguard Circuits?