Strain Gauge : Principle and Its Applications

In 1938, Edward E. Simmons and Arthur C. Ruge pioneered the strain gauge, sparking advancements in the measurement of structural strain. This innovative device serves as a sensor, detecting strain across diverse objects. Its significance lies in its utility across various fields, from geotechnical assessments of tunnels, underground spaces, buildings, and bridges to analyzing materials like concrete and masonry dams. This article comprehensively explores the strain gauge, covering its operational principles, distinctive features, and practical applications.

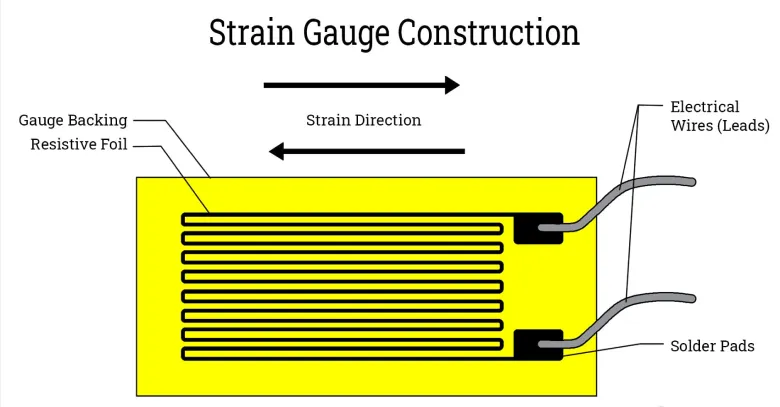

What Constitutes a Strain Gauge?

Description: A strain gauge stands as a vital instrument within geotechnical engineering, serving to quantify strain across a spectrum of structures. When subjected to an external force, the strain gauge undergoes a shift in resistance.

The fundamental composition of this gauge comprises an insulating, pliable backing that upholds a metallic foil configuration. This metallic coil is affixed onto a slender substrate referred to as a carrier, and the entire assembly is secured onto an object utilizing a suitable adhesive. As the object experiences deformation due to forces like pressure, weight, tension, and the like, the electrical resistance of the foil undergoes alteration. A Wheatstone bridge discerns this change in resistivity, correlating it with strain via a parameter termed Gauge Factor.

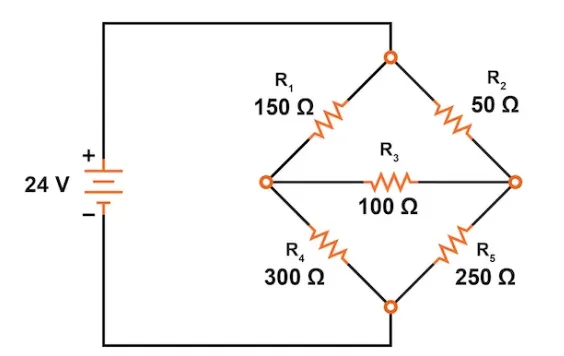

The minute alterations in the resistance of the gauge are gauged utilizing the Wheatstone bridge principle. The diagram below elucidates the typical configuration of a Wheatstone bridge, comprising four resistive arms and an excitation voltage, VEX.

The Wheatstone bridge encompasses two parallel voltage divider circuits. R1 and R2 constitute one divider circuit, while R3 and R4 form the second. The output voltage VO is determined by:

If R1/R2 = R4/R3, then the output voltage is zero, indicating a balanced bridge.

Even a slight deviation in resistance results in a nonzero output voltage. Substituting ‘R4’ with a strain gauge introduces sensitivity to resistance changes, disrupting the bridge balance and generating a nonzero voltage.

Gauge Factor of the Strain Gauge

The gauge factor GF is expressed as:

GF = (∆R⁄RG) / ε

Where:

‘ΔR’ denotes the resistance variation due to strain

‘RG’ represents the resistance of the unstrained gauge

‘ε’ signifies the strain

The typical gauge factor for metallic foils is approximately 2. The output sensor voltage SV from a Wheatstone bridge is calculated as:

SV = EV (GF. ε) / 4

Here, EV denotes the excitation voltage of the bridge.

Operation of the Strain Gauge

The functionality of a strain gauge hinges entirely on the electrical resistivity of a material or conductor. When subjected to stretching within its elastic limits, causing elongation without permanent damage, the material becomes thinner and longer, resulting in heightened electrical resistance. Conversely, compression of the material without deformation but rather broadening and shortening leads to reduced electrical resistance. The recorded electrical resistance values of the gauge offer insights into the extent of induced stress.

Excitation voltage is applied at the input terminals of the gauge network, while readings are taken at the output terminals. Typically, these connections are linked to a load and tend to remain stable over extended periods, often spanning decades. The adhesive utilized for attaching gauges varies depending on the duration of the measurement system – cyanoacrylate glue is suitable for short-term measurements, while epoxy glue is preferred for long-term applications.

Principle of Operation of the Strain Gauge

Considering that resistance is directly proportional to the length and inversely proportional to the cross-sectional area of a conductor, as defined by R = L/A,

Where,

‘R’= Resistance

‘L’ = Length

‘A’ = Cross-sectional area

It’s evident that any alteration in the size and shape of a conductor impacts its length, consequently affecting its cross-sectional area and resistance.

Typically, a standard gauge features a lengthy and slender conductive strip arranged in a zigzag pattern of parallel lines. This zigzag configuration serves to accentuate even the slightest stress between the parallel lines with utmost precision. Stress, in this context, refers to the force that opposes deformation in an object.

Rosette Strain Gauges

Strain gauge rosettes, comprising two or more gauges strategically positioned in a rosette-like arrangement, serve to assess precise strain across a surface.

Load Cells with Strain Gauges

These load cells are prevalent in various industrial settings due to their high accuracy and cost-effectiveness. Essentially, a load cell comprises a metallic body to which strain gauges are affixed. To ensure the body's robustness and minimal elasticity, materials like alloy steel, aluminum, or stainless steel are typically utilized.

Upon application of an external force, the load cell undergoes slight deformation, reverting to its original shape if not subjected to excessive loads.

When deformation occurs in the load cell, the shape of the gauge changes, leading to alterations in electrical resistance, subsequently measured as voltage.

Common types of strain gauge load cells include bending beam, pancake, single point shear beam, double-ended shear beam, wire rope clamps, among others.

Attributes of Strain Gauges

Key characteristics of strain gauges include:

Suitability for extended durations with appropriate precautions

Accurate readings despite fluctuations in temperature and other variables

Simplicity in manufacturing due to uncomplicated components

Ease of maintenance and prolonged operational lifespan

Complete encapsulation for protection against handling and installation-related damages

Applications of Strain Gauges

These remarkable traits make strain gauges invaluable in geotechnical engineering, facilitating continuous monitoring of structures such as dams and tunnels to preempt accidents. Some applications of strain gauges encompass:

Railway monitoring systems

Suspension bridges

Aerospace industry

Nuclear power facilities

FAQs

1). What is the sensitivity of a strain gauge?

The sensitivity varies according to the strain rate, which, in turn, depends on the material's grain size. It's defined as the ratio of the change in flow stress to the change in strain.

2). What is the unit of strain?

Strain is dimensionless. However, strain rate is expressed in reciprocal seconds (s-1), being the inverse of time.

3). How do I select a strain gauge?

Selection criteria include factors such as:

Gauge length and resistance

Cost-effectiveness in terms of labor

Compatibility with material and environmental conditions

4). Why is the Wheatstone bridge used for strain gauges?

The Wheatstone bridge is adept at measuring output voltages in millivolts. When connected to a bonded strain gauge, it detects minute changes in resistance. As the output voltage deviates from zero, indicating an imbalance, the bridge aids in determining the strain on the object.

5). How do you install strain gauges?

Installation involves the following steps:

These steps ensure accurate measurements and reliable performance. Additionally, in modern applications, digital image correlation (DIC) is increasingly utilized for strain measurement due to its precision. It serves as a viable alternative to traditional sensors like accelerometers, string pots, and LVDTs. Now, can you identify the primary function of a strain gauge?

Related Articles

How to Calculate Resistance in Series and Parallel

What is a Gyrocopter? All You Need to Know