How Does a Single Phase Motor Work?

What would our world look like if the electric motor had never been invented?

Single Phase Motors

Electric motors have been instrumental in shaping modern conveniences, powering everything from basic lighting and refrigeration to high-speed electric vehicles. By converting electrical power into mechanical motion, these machines have revolutionized various industries. Among the diverse range of electric motors, the AC motor stands out for its widespread use, owed to its sophistication and consistently reliable performance.

Operating on AC current and harnessing the principles of electromagnetism, AC motors serve as the backbone of rotational power generation. They are available in numerous variations, each tailored for specific applications. This article aims to delve into the realm of single-phase industrial motors, a cornerstone of the contemporary world, driving a multitude of indispensable tools. By exploring the workings, operational principles, and specifications of these motors, this discussion aims to equip designers with insights into the advantages of single-phase motors and guide them on optimal usage scenarios.

What are Single Phase Motors?

Single-phase motors belong to the family of AC motors, leveraging electromagnetic principles to produce valuable rotational energy. Operating on principles akin to squirrel cage, wound rotor, and other polyphase motors, they offer a simplified variant of these systems (further details on these motors can be explored in our articles on squirrel cage, wound rotor, and induction motors).

The term "single-phase" pertains solely to the input power, encompassing a broad spectrum of motors utilizing single-phase inputs. While commonly associated with induction motors, they can also manifest as synchronous motors. In their construction, single-phase motors encompass both stators and rotors akin to typical electric motors. However, they employ a singular winding in the stator that carries a sole AC current, and their rotor designs are typically more straightforward compared to other motor configurations.

Distinctively, these motors necessitate a starter due to their reliance on a single phase of input power, which renders them devoid of starting torque at rest.

How Does a Single Phase Motor Work?

Single-phase motors, similar to other AC motors in their utilization of stators and rotors, operate distinctly. Unlike three-phase motors where the 120-degree phase separation generates a rotating magnetic field from three AC currents in the stator windings, in single-phase motors, the magnetic field from a sole phase fluctuates between two motor poles. With just one AC current producing two magnetic field states—equal but opposing in orientation, forming an "up-down" pattern—it approximates a rotating field but not entirely.

To initiate movement in the rotor, these motors require an initial push or a force out of sync with the stator phase. When the rotor is stationary, the pulsating "up-down" magnetic field doesn't influence it as the opposing magnetic forces cancel each other perfectly.

Motor starters address this challenge by introducing an out-of-phase influence, achieved through auxiliary windings, capacitors, and similar components. This addition creates a simulated rotating magnetic field, crucial for initiating the motor's operation. For further insights into these starters, our article on motor starters provides comprehensive information.

Types of Single Phase Motors

The term "single-phase motor" solely denotes the type of input power supply and doesn't dictate the particular stator-rotor-starter configuration. When choosing a single-phase motor, several specifications akin to other AC motors remain relevant, detailed in our articles on induction motors and AC motors. This article aims to outline the various types of single-phase motors, allowing for the application of general principles to these distinct designs.

Motors employing split-phase technology

Split-phase motors integrate an additional winding external to the stator coil, essential for initiating the required phase disparity crucial for rotation. This auxiliary winding, featuring smaller wire diameter and fewer turns compared to the stator winding, deliberately incorporates higher resistance. Consequently, it becomes out of sync with the primary magnetic field due to this altered supply phase.

This split-phase winding assumes the responsibility of propelling the initial motion to kick-start rotation, while the primary winding sustains the motor's ongoing operation. To ensure smooth functionality, the starting winding needs to be disengaged—usually through a centrifugal switch on the output shaft—once the motor attains a specific percentage of its full speed, approximately around 75% of the rated speed.

As augmenting the resistance in the starting winding escalates the risk of overheating the coil, these switches become imperative for ensuring the proper and reliable functioning of split-phase motors.

Motors featuring capacitor start or capacitor start-capacitor run configurations

In these particular single-phase motors, capacitors, in conjunction with an auxiliary winding, create the crucial phase disparity necessary to initiate rotation. They resemble split-phase motors but utilize capacitance instead of resistance to alter the starter phase.

Capacitor start motors employ a centrifugal switch that disconnects the start capacitor once the motor reaches a certain speed, typically around 75-80% of its full speed. Conversely, capacitor start-capacitor run motors integrate two capacitors—a start capacitor and a run capacitor. The start capacitor leads the applied voltage, inducing a phase shift, and amplifies the motor's initial startup. As the motor reaches its rated speed, the run capacitor takes over the operation.

Motors utilizing permanent-split capacitor technology

Permanent-split capacitor motors employ a permanent capacitor in conjunction with the starting winding, eliminating the need for a centrifugal switch. The capacitor operates continuously during motor operation, unlike the start capacitor used in prior designs, thus lacking the additional boost. However, these motors derive an advantage from foregoing a separate starting mechanism (such as a switch or button), as the run capacitor, in tandem with the auxiliary winding, passively alters the phase of the single-phase input.

Notably, permanent-split capacitor motors offer reversibility and generally exhibit greater reliability compared to other single-phase motors.

Shaded Pole Motors

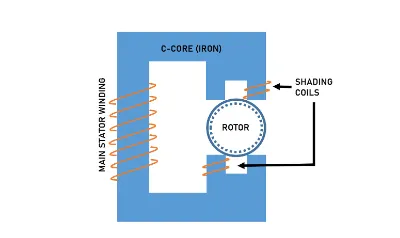

This particular type of single-phase motor operates without the need for additional windings or starters to initiate movement. Instead, it relies on a configuration akin to the one depicted in Figure 1 below:

Diagram - Shaded pole motor arrangement

Figure 1: Shaded pole motor arrangement. Note the shading coils, extending from the main stator winding.

Compared to other single-phase motors, this motor is more straightforward, devoid of supplementary starter circuits or switches. The C-core motor housing, typically constructed from magnetically conductive material like iron, facilitates the transfer of the pulsating magnetic field generated by the main stator winding to the rotor.

This motor's poles are asymmetrically divided into two unequal sections, with two "shading" poles formed by extending the primary stator winding into smaller windings on one of these halves, as illustrated above. Upon the entry of single-phase AC current into the C-core, it "shades" these wound portions, inducing a lag in the magnetic field through the shaded region. This lag is generated by the shading coil, which produces an opposing magnetic field, thereby retarding the magnetic flux. Consequently, an uneven distribution of inductive forces across the rotor prompts its rotation.

Utilization and Criteria for Selection

Different applications demand particular single-phase motors. Table 1 illustrates the qualitative operational characteristics of each motor type.

Split-phase motors, characterized by a straightforward design, offer reduced cost but lower performance. They suffer from low starting torque and are prone to overheating due to their resistive starting mechanism. Ideal for low-torque applications like handheld grinders, small fans, and fractional horsepower needs, they should be avoided for high-torque or high-cycle-rate applications to prevent burnout.

Capacitor start motors provide improved starting torque compared to split-phase ones and can endure high cycle rates. Widely applicable across various general-purpose industrial uses such as belt-driven conveyors, large blowers, and geared applications, they are costlier than split-phase motors.

Permanent-split capacitor motors, although featuring low starting torque, excel under high cycle rates with excellent efficiency and reliability. Reversible and speed-controllable, they lack a starting mechanism, making them suitable for garage doors, gate openers, and low-torque applications requiring instant reversing.

Capacitor start-capacitor run motors combine the advantages of permanent-split capacitor and capacitor start motors but come at a higher cost. With high starting torque, they power demanding applications like air compressors, high-pressure pumps, and 1-10hp applications efficiently and reliably.

Shaded pole motors, often considered disposable due to their simplicity and affordability, lack the torque, efficiency, and reliability of other single-phase motors. Best suited for low-horsepower needs such as bathroom fans, hairdryers, electric clocks, and toys, they serve well in fractional horsepower projects where cost is a primary consideration.

Summary

This piece provides insights into the nature and functionality of single-phase industrial motors.

Rlated Articles

Do ECM Motors Have Capacitors?

How Does a Single Phase Motor Work?