Multilayer PCB Guide: Structure, Components & Applications

What Is a Multilayer PCB?

A multilayer PCB (printed circuit board) is a circuit board, a redundant term that represents a circuit board containing three or more conductive copper layers layered together with insulating material. In contrast to single or dual-layer PCBs, multilayer boards incorporate interior signal, power and ground layers that allow complex circuit routing in a small area. Multilayer PCBs are very common in current-day electronics, where one needs a high density of components, electrical performance, and reliability.

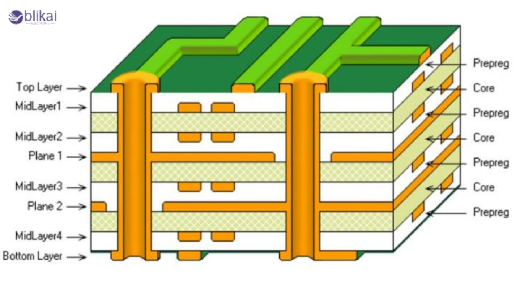

Basic Structure of a Multilayer PCB

A multilayer PCB is constructed by the alternation of dielectric insulation and copper foil. The core gives the material mechanical strength, and the prepreg layers hold the copper layers together in the lamination process. Surface mount components are placed on external layers, and internal layers are used to either signal route, power route or ground reference plane. This layered structure improves electrical stability and reduces interference.

Common Layer Stackups in Multilayer PCBs

A 4-layer PCB generally has two signals and two power as well as ground planes, so it is suitable where there is a microcontroller or an embedded system. Higher routing flexibility and enhanced signal integrity are provided to high-speed designs by making use of six and eight-layer PCBs. Servers, telecommunication equipment and sophisticated industrial electronics are designed to use high-layer-count PCBs, which may have many more than ten layers.

Key Components Used on Multilayer PCBs

Multilayer PCBs are used to support a great variety of electronic components. Signal conditioning and power filtering are done by passive components like resistors, capacitors and inductors. Logic and control functions are done by active components such as ICs, processors, and memory chips. Protection components, connectors, and power management devices are also usually combined to guarantee that they operate in a stable and reliable manner.

Interconnection Technologies in Multilayer PCBs

Vias offer electrical connections between layers. Through-hole vias are also vias that are made through the entire board, whereas there are blind and buried vias, which are used to save space by connecting specific layers. Microvias, typically implemented in HDI designs, allow high-density routing to an extremely high degree, and are needed in small consumer electronics and high-speed communication equipment.

Materials Used in Multilayer PCB Manufacturing

FR-4 is a widely used laminate since it offers a compromise between its price and performance. Materials with high Tg would be used in a high-temperature setting, and high-frequency laminates like PTFE material and Rogers materials are used in RF and microwave applications. Thermal management materials have been incorporated, usually to dissipate heat in power-dense designs.

Multilayer PCB Manufacturing Process

The manufacturing process begins with layer imaging and copper etching. Individual layers are aligned and laminated under heat and pressure. Drilling creates via holes, which are then plated to establish electrical connections. Surface finishing processes such as ENIG or HASL protect exposed copper and prepare the board for assembly.

Design Considerations for Multilayer PCBs

Multilayer PCB design is a concerted effort on signal integrity, impedance control, as well as stack-up planning. A separated power and ground plane diminishes noise and EMI. Copper pours and via stitching are various methods of thermal management that control heat. Good design practices ensure manufacturability and long-term reliability.

Advantages of Multilayer PCBs

Multilayer PCBs have better circuit density, signal integrity and EMI control due to the provision of dedicated power and ground planes in the board structure. This enables designers to trace out complicated and high-speed circuits on a smaller footprint with stable electrical performance. Multilayer structures are also more reliable since they use less external wiring and also allow uniform control of impedance, which is more useful in complex electronic systems.

Disadvantages of Multilayer PCBs

Although very advantageous, multilayer PCBs are more expensive to manufacture and to design than single- or double-layer boards. The process of lamination, accurate alignment and via structures raises production time cost. Moreover, internal layers are hard to reach and hence troubleshooting and repairing are harder and in most cases uneconomical in low-volume projects or cost-sensitive projects.

Typical Applications of Multilayer PCBs

Consumer Electronics

The multilayer PCBs are broadly used in smartphones, tablets, laptops, and wearable devices, in which having a compact size and significant functionality is of great importance. The dense placement of components, fast signal routing, and reliable power distribution can be achieved using multiple internal layers, enabling processors, memory, sensors, wireless modules, among others, to be placed in the small space.

Computing and Data Processing Equipment

Multi-layered PCBs are used in desktop computer applications, servers and data centre equipment technology to carry sophisticated digital circuits with critical signal quality applications. Specialized power and ground planes can be used to control noise and impedance, and multilayer boards are required in CPU, graphics card, memory cards, and high-speed interfaces.

Telecommunications and Networking Systems

Multilayer PCBs are significant in routers, switches, base stations and optical communication equipment. Their layered design allows high frequency and high-speed transmission of signals and reduces crosstalk and EMI, thereby providing reliable data transmission in challenging network environments.

Industrial Automation and Control Systems

Multilayer PCBs in PLCs offer strong electrical functionality and high reliability over a long period. They allow control logic, power management, and communication circuits to be integrated on the same board, and they can keep operating in industries.

Automotive Electronics

The modern car has multilayer PCBs in engine control systems, adaptive driver control systems, infotainment systems and battery management systems. These boards offer the thermal stability, vibration resistance, and electrical performance required for safety-critical and high-reliability automotive applications.

Medical Electronics

Multilayer PCBs find a wide application in medical imaging systems, patient monitoring systems, and diagnostic systems. The fact that they can be used in complex circuitry in small layouts can assist them in achieving the high performance, reliability and safety requirements needed in healthcare electronics.

Aerospace and Defense Applications

In avionics, radar systems, navigation equipment, and military electronics, multilayer PCBs provide high reliability and controlled signal performance. The stacked layout aids the higher functionality along with the strictness of the durability, signal quality, and environmental qualities. Smartphones, computers and consumer electronics have large uses of multilayer PCB. They are important in automation in industries, automotive control units, network equipment, medical equipment, and aerospace systems, where stability and performance are crucial.

Multilayer PCB vs HDI PCB

Whereas both multilayer and HDI PCBs rely on multiple layers, HDI boards rely on the use of microvias and finer traces to be denser. The majority of intricate designs are fabricated on multilayer PCBs and only under a need to possess a high level of miniaturisation and speedy performance, HDI PCBs have been selected.

How to Choose the Right Multilayer PCB for Your Project

When making the decision on the right multilayer PCB, the required number of layers, electrical functions, and the surrounding conditions of the multilayer PCB must be determined. The used materials, cost and the capacity of production should be considered equally to get the optimum of it.

FAQs

How many layers does a multilayer PCB have?

A multilayer PCB usually has four or more copper layers laminated together with insulating material. Most commercial multilayer PCBs use between 4 and 12 layers but the advanced networking, server, and aerospace boards can use more than 20 layers to support the complex routing, power distribution, and the signal integrity.

When should you use a multilayer PCB?

This is due to the fact that a multilayer PCB is required whenever the circuit requires either high density of components, controlled impedance, small size or low noise. It is used in high-speed digital circuits, mixed-signals as well as where the PCB performance or layout requirements cannot be met with either single or double-layered PCBs.

Are multilayer PCBs repairable?

Multilayer PCBs are also not easily repairable as internal layers are not easily accessible. Even though superficial aspects and evidence can be repaired, internal damages might make repair impossible in most situations. For high-reliability or mass-produced electronics, replacement is usually more cost-effective than repair.

Which industries use multilayer PCBs the most?

Consumer electronics, telecommunications, automotive electronics, industrial automation, medical devices, and aerospace systems are the most common places for multilayer PCBs. These industries apply multilayer boards as they have the ability to support complex circuits, continuous power provision and dependability.

What is the main advantage of a multilayer PCB?

The main advantage of multilayer PCB is that it enables incorporation of more complex circuitry on a lesser area and improves electrical performance. Dedicated power and ground planes lead to reduction of EMI, signal integrity and high speed or high frequency.

Is a multilayer PCB better than a double-layer PCB?

Multilayer PCB is better than the double-layered PCB because it offers more routing space, increased noise suppression performance, and thermal conductivity. Simple, low-cost electronics with very few routing considerations still see use on double-layer PCBs.

Some images are sourced online. Please contact us for removal if any copyright concerns arise.

How does an Accelerometer Work?

Transformer Core Faults: Hazards, Causes, Types, Testing, and Remediation

How Does a Resistor Work [Fully Explained]

Cr2 vs Cr123: Which Battery Is Right for You? [Explained]

What is a RF Modulator? Everything You Need to Know

LR44 Battery: Everything You Need to Know [2024 Updated]

What is an Mechanical Comparator?

What is a High Pass Filter? Features, and Applications

What is a Piezoelectric Transducer?Features, Specification and Applications

Air Circuit Breaker:Features, Specification and Applications