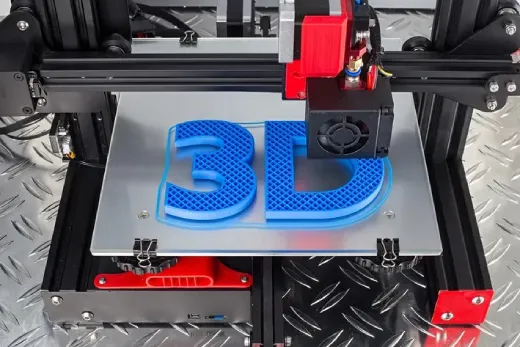

What is 3D printing? Everything You Need to Know

Also known as Additive Manufacturing, 3D printing is a rapid prototyping technology. Its working principle is mainly based on digital model files, using adhesive materials such as powdered metals or plastics, to construct objects layer by layer through printing. Simply put, if an object is sliced into many thin layers, 3D printing works by printing these layers one by one, with each layer covering the one below and bonding to it, until the entire object is printed.

Since its emergence in the mid-1990s, 3D printing technology has been widely used in multiple fields, including mold manufacturing, industrial design, jewelry, footwear, architecture, engineering and construction, automotive, aerospace, dentistry, and medical industries. Moreover, 3D printing has demonstrated its enormous potential in some specialized areas, such as the University of California, San Diego, which used 3D printing technology to manufacture spinal scaffolds mimicking the structure of the central nervous system, successfully helping rats recover motor functions.

The emergence and development of 3D printing technology have greatly propelled innovation and transformation in the manufacturing industry, bringing endless possibilities for future production and life.

The Development History of 3D Printing

Early Exploration and Patent Birth (1980s)

In the 1980s, 3D printing technology began to emerge. A pivotal year was 1986 when Charles Hull successfully developed Stereolithography (SLA) and obtained related patents. This technology laid the foundation for 3D printing, leading to the founding of 3D Systems, the world's first company to manufacture 3D printing equipment. In the same year, he also created the widely used STL file format. In 1987 and 1988, other researchers respectively developed Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM) technologies, which further diversified the applications of 3D printing.

Technological Development and Commercial Applications (1990s)

Entering the 1990s, 3D printing technology continued to evolve. In 1993, Professor Emanual Sachs of MIT invented the powder bed and inkjet 3D printing (3DP) technology, which bonded metal, ceramics, and other powders with adhesive, expanding the application fields of 3D printing. Simultaneously, several companies began to commercialize 3D printing equipment, such as ZCorp obtaining the sole license for 3D printing technology from MIT in 1995 and initiating the development of 3D printers.

Widespread Applications and Innovation Breakthroughs (2000s to Present)

Entering the 21st century, 3D printing technology has seen more widespread applications. In addition to traditional fields such as industrial design, model making, and prototyping, it has entered multiple sectors including healthcare, aerospace, automotive, and architecture. For example, in 2010, the world's first car printed by a 3D printer, Urbee, was unveiled, demonstrating the potential of 3D printing in the transportation sector. Meanwhile, with the emergence of consumer-grade 3D printers, ordinary users can also purchase 3D printers to manufacture items they desire.

Advantages of 3D Printing

Customized Production:

3D printing technology enables on-demand manufacturing, making it ideal for producing customized parts and products. This highly personalized production meets the market's demand for unique products, providing designers and consumers with greater creative freedom.

Rapid Prototyping:

Traditional prototyping often involves complex processes and long waiting times, while 3D printing technology can rapidly produce prototypes, significantly shortening the product development cycle. This enables designers and engineers to test and validate product designs earlier, enhancing product development efficiency.

Complex Structure Manufacturing:

Traditional manufacturing techniques often struggle with producing complex internal structures, whereas 3D printing technology can easily achieve this. It can manufacture parts with intricate internal channels, voids, and shapes, thereby improving product performance and functionality.

Material Savings:

3D printing technology builds objects layer by layer, using only the necessary materials, thus reducing waste. Compared to traditional subtractive manufacturing, it saves a significant amount of raw materials, lowering production costs.

Lightweight Design:

Through optimized structural design, 3D printing can produce lighter and stronger parts and products. This helps reduce product weight, improve efficiency, particularly significant in aerospace and automotive fields.

Multi-material Printing:

3D printing technology can incorporate multiple materials within the same object. This capability allows designers to create parts with different performance characteristics such as hardness, elasticity, conductivity, etc., meeting complex functional requirements.

Environmental Sustainability:

3D printing technology can reduce waste and energy consumption, contributing to lower environmental pollution. Additionally, by using renewable materials and recycling waste, it can also promote sustainable development.

Disadvantages of 3D Printing

Material Constraints:

Currently, the variety of materials available for 3D printing remains limited, especially for the specialized materials required in high-end industrial applications. Despite researchers' efforts to develop new printing materials, many materials still cannot be effectively used for 3D printing, limiting its applications in certain fields.

Machine and Technology Limitations:

Existing 3D printing technologies still have certain limitations in terms of printing precision, speed, and size. For instance, achieving ideal results for very fine or large objects may be challenging with 3D printing. Additionally, the printing process may be unstable for some complex structures and shapes, resulting in poor final product quality.

Cost Issues:

Although 3D printing can lower production costs in some cases, overall, the acquisition and maintenance costs of 3D printing equipment remain relatively high. This limits the application of 3D printing technology in some cost-sensitive areas.

Intellectual Property and Ethical Challenges:

The widespread adoption of 3D printing technology makes replication and sharing of designs easier, potentially leading to issues of intellectual property infringement. Additionally, some individuals may exploit 3D printing technology to produce illegal or dangerous items, raising concerns about ethics and safety.

Post-processing and Surface Smoothness:

Finished products from 3D printing often require post-processing to achieve the desired smoothness and accuracy. This increases the complexity and cost of the production process and may affect the quality of the final product.

Environmental Impact:

While 3D printing can reduce waste and energy consumption, certain printing processes may produce harmful emissions, impacting the environment. Additionally, discarded 3D printing materials and equipment may become new environmental issues.

Applications of 3D Printing

Medical Field:

The prospects for 3D printing technology in the medical field are vast. For example, 3D printing technology can be used to manufacture customized medical implants such as teeth, bones, and joints to meet the specific needs of patients. Additionally, this technology can also be used to print biological tissues, organs, and drugs, providing new solutions for tissue engineering and regenerative medicine.

Aerospace Industry:

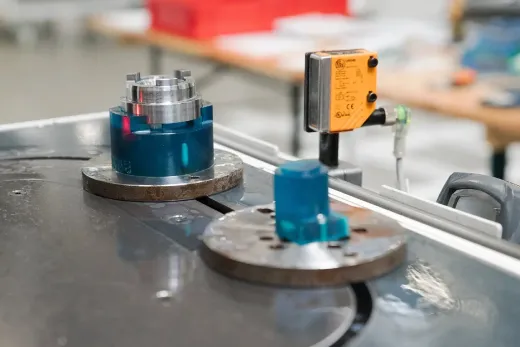

The application of 3D printing technology in the aerospace industry is equally significant. Because this technology can manufacture parts with complex internal structures and lightweight characteristics, it can be used to produce critical components of aircraft, rockets, and other aerospace vehicles, improving performance and reducing costs.

Automotive Manufacturing:

In the automotive manufacturing industry, 3D printing technology can be used to manufacture prototype vehicles, custom parts, and complex internal components. This technology can accelerate the vehicle development cycle, improve production efficiency, and reduce production costs.

Construction Sector:

In the construction sector, 3D printing technology can be used to manufacture architectural models, personalized decorations, and partial components of building structures. This technology can reduce construction costs, improve construction efficiency, and provide architects and designers with more innovative possibilities.

Consumer Electronics Sector:

With the increasing demand for personalized products, the application of 3D printing technology in the consumer electronics sector will gradually expand. Consumers can use 3D printing technology to manufacture personalized phone cases, headphones, speakers, and other products to meet their unique aesthetic and practical needs.

Education Sector:

3D printing technology can also be used in the education sector to help students better understand spatial structures and object forms. Through 3D printing technology, students can create physical models to deepen their understanding of subjects such as science, engineering, and mathematics.

The Future of 3D Printing

Technological Advancements:

The precision and speed of 3D printing will continue to improve. With algorithm optimizations and hardware upgrades, future 3D printers will be able to produce even finer and more complex structures, while printing speeds will significantly increase, thereby enhancing production efficiency.

Material Innovation:

In the future, 3D printing materials will become more diverse, expanding beyond traditional materials like plastics and metals to include new materials such as biomaterials and composites. The emergence of these new materials will broaden the application scope of 3D printing technology, particularly in fields like healthcare and bioengineering.

Intelligence and Automation:

3D printing technology will evolve towards intelligence and automation. By integrating technologies like artificial intelligence and machine learning, 3D printers will be capable of self-optimization, fault diagnosis, and other functions, enhancing the stability and reliability of the production process.

Deepening Industry Applications:

As 3D printing technology becomes more widespread and mature, its applications will gradually penetrate various industries. In addition to existing fields like aerospace, automotive manufacturing, and medical devices, 3D printing technology will also expand into more sectors such as construction, fashion, consumer electronics, bringing innovation and transformation to these industries.

Personalized Customization:

With the increasing demand for personalized products, 3D printing technology will be more extensively applied in the field of personalized customization. Consumers will be able to design and print products tailored to their needs through online platforms, achieving genuine personalized customization.

Sustainability:

In the future, 3D printing technology will place greater emphasis on sustainability. By optimizing printing processes, reducing waste generation, and using eco-friendly materials, 3D printing technology will strive to reduce its environmental impact, realizing green manufacturing.

DC Transmission: Types, Applications & Advantages

What TLV3201AQDCKRQ1 Voltage Comparator is and How It works

Exploring Electronic Components: Innovations and Applications

Embedded Systems vs Microcontrollers: What's the Main Differences?

What is a Memory Card? Types, Work, and Applications

DIY Electronics Project for Beginners: Pick the Best One for You

RJ45 Color Code: All You Need to Know (Guide)

RJ45 Connector: Everything You Need To Know (Guide)

2N7000 vs BS170: What's the Main Differences?

What are Flat Flex Ribbon Jumpers(FFRJs)? All Explained