What is Thermal Management: Applications, Features

The management of thermal energy is a crucial aspect of modern technology for maintaining the performance and longevity of electronic devices and systems. Whether you're working with consumer electronic devices, industrial machinery, automotive systems, or data centers, thermal management solutions are essential. In order to prevent overheating, increase efficiency, and extend the lifespan of components in diverse technological environments, we examine the various applications and key features of thermal management.

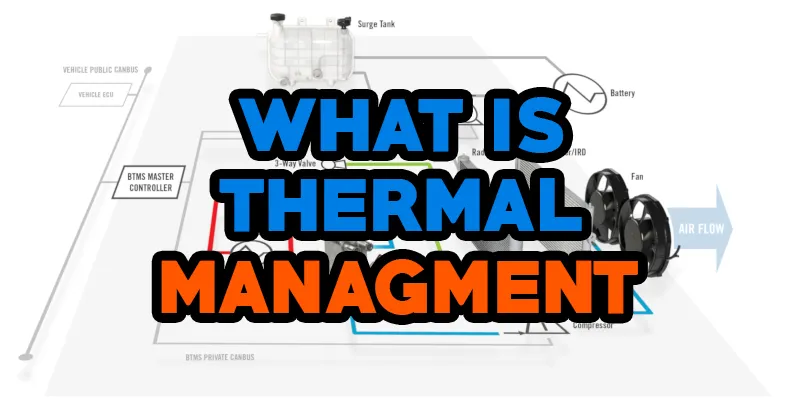

What is Thermal Management?

It refers to the process of maintaining safe and efficient operating temperatures for electronic devices and systems. Dissipating heat generated by electronic components uses a variety of techniques and technologies, preventing overheating and potential damage. As excessive heat can cause component failure, reduce efficiency, and shorten the lifespan of electronic devices, proper thermal management is critical to maintaining their performance, reliability, and longevity.

Active cooling techniques, such as fans and liquid cooling systems, and passive cooling, such as heat sinks, are key methods of thermal management. Thermal design optimization and the use of thermally conductive materials are also aspects of advanced techniques. Heat management solutions are essential in a variety of applications, including consumer electronics and computer hardware, industrial equipment, and automotive systems, where they prevent degradation in performance and provide stable operation. Check out more on Blikai.com.

Features

Heat Dissipation Techniques: Thermal management involves transferring heat from electronic components using different heat dissipation techniques. Thermal interface materials (TIMs), heat sinks, and heat spreaders are passive cooling methods that don't require an external source of power. Through active cooling methods like fans, blowers, and liquid cooling systems, heat is transferred mechanically. This method ensures safe operation of components. Thermal control for high-performance applications can be achieved with thermoelectric coolers and phase-change materials.

Thermal Interface Materials (TIMs):

It is important for thermal management to have TIMs in place because they improve the thermal conductivity between the heat-generating components and the heat sinks. Providing optimal thermal contact and efficient heat transfer, these materials fill microscopic gaps and irregularities on surfaces. A thermal paste, a pad, or an adhesive tape are common types of TIMs, each of which offers a different level of thermal conductivity and ease of application. Electronic devices benefit greatly from heat dissipation when the appropriate TIM is selected.

Thermal Design Optimization: An electronic system's thermal performance can be improved by optimizing its thermal design. Designing enclosures that facilitate effective airflow, selecting appropriate cooling solutions, and optimizing component placement are all essential parts of this process. In order to identify potential hotspots and design efficient thermal management systems, engineers often use computational fluid dynamics (CFD) simulations and thermal modeling tools. Electronic devices operate more reliably under different environmental conditions when they are thermally designed properly.

Heat Sinks and Spreaders: Fundamental components of thermal management systems are heat sinks and heat spreaders. Metal or copper heat sinks typically have fins or other structures to increase surface area for heat dissipation, and are made from thermally conductive materials such as aluminum or copper. On the other hand, heat spreaders prevent localized overheating by distributing heat across a larger area. Power electronics and CPUs require these components to manage heat.

Active Cooling Solutions: A dynamic thermal management solution, such as fans, blowers, and liquid cooling, moves heat away from components through active cooling. A liquid cooling system absorbs and transfers heat from a radiator to a fan, where it is dispersed into the surrounding air. Fans and blowers enhance airflow within enclosures. Electronic systems that require high performance and dense packing require active cooling to maintain safe temperatures since passive cooling alone cannot keep them cool.

Thermal Monitoring and Control: Modern thermal management strategies rely on thermal monitoring and control systems. Real-time data is provided by sensors and thermal management software for adjusting cooling mechanisms dynamically based on the temperature of critical components. In addition to preventing overheating, this proactive approach extends the life of electronic devices and ensures optimal performance. Software that manages thermal environments can also alert users to critical temperature thresholds and shutdown systems when they reach them, preventing catastrophic damage.

Material Selection: Thermal management relies heavily on the choice of materials. A heat sink, spreader, or other thermal management component that has a high thermal conductivity is typically constructed of copper, aluminum, or ceramic materials. As well as phase-change materials and thermoelectric materials, advanced applications use these materials to efficiently absorb and dissipate heat. Thermal management systems are more efficient when they are constructed with the right materials, which ensures effective heat transfer.

Integration with System Design: A seamless integration of thermal management into the overall system design is essential for effective thermal management. As part of this process, thermal factors must be considered early in the design process, and all components, including PCBs, enclosures, and power supplies, must be able to dissipate heat efficiently. Electronic devices meet their operational requirements without compromising safety or efficiency with integrated thermal management solutions that balance performance, reliability, and cost.

Applications

Consumer Electronics: Maintaining performance and extending the lifespan of consumer electronics devices requires proper thermal management. A smartphone, tablet, laptop, or gaming console generates a significant amount of heat due to their compact design and powerful processors. A variety of thermal solutions are utilized to dissipate heat efficiently, including heat pipes, thermal interface materials, and micro fans. The heat generated by processors and batteries on advanced smartphones, for example, is managed by graphite sheets and vapor chambers, ensuring user comfort and device reliability.

Automotive Industry: Whether it is an internal combustion engine vehicle or an electric vehicle (EV), thermal management is essential to the automotive industry. Coolant systems, oil coolers, and radiators manage the heat caused by internal combustion engines. Battery, power electronics, and electric motor temperatures are regulated by thermal management systems in electric vehicles. For batteries to perform and last as long as they should, as well as for powertrain efficiency and reliability, thermal management is essential. A number of technologies are being used to enhance thermal control in EVs, such as liquid cooling systems and phase-change materials.

Data Centers: A data center is home to thousands of servers, each of which generates considerable heat, making it essential to ensure that these servers do not overheat and that they are continuously operating. The thermal load is managed by advanced cooling solutions, such as air conditioning, liquid cooling, and immersion cooling. In order to optimize airflow and reduce energy consumption, hot and cold aisle containment strategies are used. Additionally, real-time temperature tracking and control software optimizes cooling systems in real-time to reduce energy consumption and maintain optimal conditions.

Aerospace and Defense: Electronic systems are sensitive to harsh environments, so thermal management ensures their reliability and performance. It is necessary to provide robust thermal solutions for aircraft, satellites, and military equipment that operate at extreme temperatures. A number of cooling techniques, including heat sinks, thermal interface materials, and thermoelectric coolers, can be used to manage heat. Electronic components in satellites, for instance, are subjected to intense solar radiation and vacuum conditions during space missions, so thermal management systems ensure their functionality.

Renewable Energy Systems: Solar panels and wind turbines are among the renewable energy systems that require thermal management to enhance efficiency and reliability. Overheating in solar panels reduces energy conversion efficiency, which can be prevented by effective heat dissipation. Thermal load management is accomplished using advanced materials and cooling techniques. By regulating the temperature of power electronics and generators, thermal management systems ensure efficient operation of the wind turbine and prevent component failure due to thermal stress.

Medical Devices: Patient safety and device performance are both impacted by thermal management in medical devices. In the course of operation, medical imaging equipment, such as MRIs and CT scans, generates a significant amount of heat. The devices are operated within safe temperature ranges with effective cooling solutions, including liquid cooling systems and thermal interface materials. Wearable health monitors and insulin pumps are also portable medical devices that require efficient thermal management. The device's portability and usability aren't compromised by sophisticated materials and design techniques that manage heat.

Industrial Equipment: Maintaining machinery and electronic systems' performance and reliability requires thermal management in industrial settings. A motor, drive, or control panel that generates high power generates considerable heat when it is in operation. Dissipating heat and preventing overheating is commonly accomplished with heat sinks, fans, and liquid cooling systems. Precision temperature control is also important for high-temperature manufacturing processes, such as welding and metal forming, where temperature control ensures product quality and efficiency.

Telecommunications: In order to ensure uninterrupted operation, telecom equipment, including routers, switches, and base stations, uses effective thermal management. Devices like these frequently operate continuously and produce a considerable amount of heat, particularly in densely populated areas. A communication network's performance and reliability are maintained by thermal solutions, such as heat sinks, fans, and advanced airflow designs. Passive cooling techniques and weatherproof enclosures are also needed to protect outdoor equipment from extreme temperature changes.

Final Verdict

Through thermal management, electronic devices are able to perform optimally and last longer. The use of thermal management in consumer electronics, automotive systems, data centers, aerospace, renewable energy, medical devices, industrial equipment, and telecommunications addresses heat challenges by combining passive and active cooling techniques, advanced materials, and real-time monitoring. In addition to preventing overheating, effective thermal management increases energy efficiency, reliability, and safety. Modern technological systems can only be designed and maintained if their applications and features are understood.