Circuit Breakers:Types and Applications

In our contemporary lifestyle, electricity plays an indispensable role, powering nearly every aspect of our lives. Whether it's sourced from the mains or a battery, maintaining control over electrical systems is imperative. Any malfunction in the electrical supply can lead to damage or, in extreme cases, pose a serious threat to life. To mitigate these risks, various protective devices, including circuit breakers, are employed.

What is a circuit breaker?

A circuit breaker is a mechanical switch designed to automatically safeguard a circuit from damage caused by excessive current flow. It functions by interrupting the circuit when it detects a substantial surge in current, typically resulting from overloading or a short circuit. Additionally, it can be manually operated to open the circuit for maintenance purposes or to address faults. The circuit breaker ensures the safe opening and closing of a circuit, effectively shielding it from potential damage.

When the current surpasses the rated current, the circuit breaker interrupts the power supply to the circuit. This excessive current can arise from various factors, including overloading, short circuits, voltage spikes, and more. Overloading occurs when the connected load draws a current exceeding the rated limit. A short circuit, on the other hand, arises when two exposed wires come into unintended contact.

What can the Circuit Breaker do?

The primary goal of a circuit breaker is to safely interrupt the circuit, encompassing the following key aspects:

Momentarily Withstand Fault Current:

Requirement: The circuit breaker must withstand the fault current for a brief period.

Safely Break Open the Circuit:

Requirement: The circuit breaker should safely open the circuit upon detecting a fault.

Quickly Extinguish the Arc:

Requirement: The circuit breaker needs to swiftly extinguish the arc generated during the interruption.

Terminals Withstand Voltage After Breaking:

Requirement: Its terminals should endure the voltage even after the circuit is interrupted.

Prevent Arc Re-Striking:

Requirement: The circuit breaker should prevent the re-striking of the arc.

The circuit breaker withstands the fault current briefly, allowing other circuit breakers to address the fault. It is engineered to endure a specific range of fault current without causing damage to its terminals.

Upon detecting the fault current, the circuit breaker trips and interrupts the current flow. The mechanism for breaking open the circuit involves utilizing stored mechanical energy, such as a spring or a blast of compressed air, to separate the contacts. Alternatively, it can leverage the fault current for contact separation through thermal expansion or an electromagnetic field, often implemented using a solenoid.

Following the separation of contacts, the subsequent critical step is arc extinction. The arc, generated due to the high voltage between contacts, has the potential to damage the circuit breaker contacts or terminals due to the excessive heat produced by the high current.

Mediums used for Arc Extinction

The electrical arc endeavors to maintain the circuit, allowing the current to persist. To mitigate this, it necessitates extinguishing, and diverse types of circuit breakers employ various insulating or dielectric mediums for arc extinction, including:

- Air

- Vacuum

- Insulating Oil

- Insulating Gas (e.g., SF6 - Sulphur hexafluoride)

Apart from the medium utilized for arc quenching, diverse arc extinction techniques are employed to swiftly and securely eliminate the arc.

Methods used for Arc Extinction

Cooling of Arc: The arc induces heat in the air molecules, causing ionization and reducing air resistance. Cooling the arc results in the recombination of ionized particles into their natural state, enhancing the dielectric strength of air molecules. As the medium's resistance increases, the voltage needed to sustain the arc also rises, leading to a decrease in current and arc quenching.

Air Blasting: Employed in air blast circuit breakers, this method quenches the arc with a blast of compressed air. Ionized air particles are substituted with non-ionized air molecules possessing higher dielectric strength. This increase in resistance reduces the current, ultimately extinguishing the arc.

Increasing the Length of Arc: The arc's length is directly proportional to its voltage. Extending the arc length by separating the contact terminals increases the voltage required to sustain it, resulting in extinguishment.

Reducing Cross-section of Arc: Another approach involves diminishing the arc's cross-section by reducing contact sizes. This increase in voltage requirement extinguishes the arc.

Deflecting the Arc: This technique involves creating a magnetic field to deflect the arc, directing it into an arc chute in the circuit breaker. Here, the arc cools off and extinguishes.

Dividing or Splitting the Arc: Multiple contacts are provided to split the arc into smaller arcs in series. This increases the arc's length and resistance, leading to a reduction in current and eventual extinguishment.

Zero Current Quenching: Common in AC circuit breakers, this method exploits the multiple zero currents in an AC waveform. The circuit opens precisely at the point of zero current to prevent the generation of an arc.

Using Charged Capacitor in Parallel: Employed in DC circuit breakers, this technique compensates for the lack of natural zero currents in DC. A charged capacitor with an inductor is introduced in parallel to create an artificial zero current, extinguishing the arc.

In essence, a circuit breaker is imperative for every line to safeguard against hazards or disasters. The manufacturing of circuit breakers considers various features, including:

- Intended Voltage Applications

- Alternating or Direct Current

- Location of Installation

- Design Characteristics

- Method and Medium Used for Current Interruption (Arc Extinction)

Circuit breakers are broadly classified into two types:

- AC Circuit Breaker

- DC Circuit Breaker

AC Circuit Breaker

AC, or alternating current, refers to electricity where the voltage and current fluctuate, crossing the zero value multiple times per second. The energy at these zero points can be harnessed to interrupt the circuit without generating an arc.

Circuit breakers designed for AC differ significantly from those used in DC circuits. The inherent zero crossings in AC provide numerous opportunities each second for the arc to extinguish itself.

The strength of the arc is directly related to the voltage level. Low-voltage arcs are easily quenched, but extinguishing high-voltage arcs requires a more sophisticated approach. Therefore, circuit breakers are categorized based on their voltage levels.

High Voltage AC Circuit Breaker

The definition of high voltage varies depending on the context. The International Electrotechnical Commission (IEC) considers voltages exceeding 1000V as high. At such voltages, arcs are challenging to extinguish. Circuit breakers designed for making and breaking contacts at these voltages are known as high-voltage (HV) circuit breakers.

Arc extinction in high-voltage circuit breakers can be achieved using various methods. HV circuit breakers may or may not use oil for arc extinction, leading to two types:

Oil Circuit Breaker

- Oil-Less Circuit Breaker

- Oil Circuit Breaker

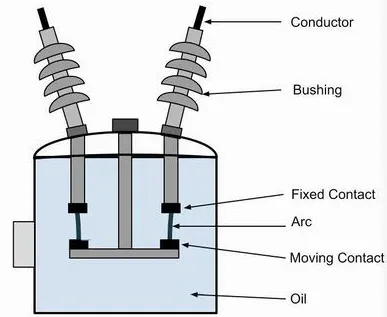

An oil circuit breaker employs oil as a dielectric or insulating medium to quench the arc. This type of circuit breaker, one of the oldest for high voltages, primarily utilizes transformer oil. The oil in these circuit breakers possesses excellent insulating properties, surpassing those of air. The circuit breaker contacts are immersed in the oil, which quenches the arc when the contacts separate. The heat generated by the arc is dissipated within the oil.

When the circuit breaker (CB) opens its current-carrying contacts within the oil, the gap between the contacts begins to widen. Initially, there is a minimal separation between the contacts, but there is also a high voltage gradient. Consequently, the oil between the contacts undergoes ionization, creating an arc.

The arc produces significant heat and vaporizes the surrounding oil, primarily decomposing it into hydrogen gas. Rapidly generated hydrogen gas bubbles surround the contact, reaching volumes nearly ten times that of the oil. This oil surrounding the gas bubbles exerts substantial pressure, enhancing the de-ionization of the medium. The de-ionization increases the dielectric strength of the medium, leading to arc quenching at the zero crossing of the current.

Additionally, the cooling effect of the oil and gas bubbles contributes to arc quenching.

Based on the quantity of oil utilized in an Oil Circuit Breaker (OCB), they are categorized into two types:

Bulk Oil Circuit Breaker (BOCB)

- Minimum Oil Circuit Breaker (MOCB)

- Bulk Oil Circuit Breaker (BOCB)

A Bulk Oil Circuit Breaker (BOCB) utilizes insulating oil to quench the arc and insulate live contacts from the earthed parts of the circuit breaker. This type of circuit breaker employs oil in large quantities. It features an iron tank containing the insulating oil, with both fixed and moving contacts submerged in the oil. Upon breaking the contacts, the arc generates heat and produces gas, pressurizing the oil inside the tank. The tank should not be entirely filled with oil, and it must be sturdy enough to withstand the gas pressure. A gas vent is provided for the safe release of gas.

The arc is quenched by the compressed gas produced by the arc's heat. As the moving contacts separate, the distance between the contacts increases, raising the arc's resistance. Additionally, the cooling effect of the gas aids in arc quenching.

BOCB is further classified based on the division of arcs for rapid extinguishing:

Single Break Bulk Oil Circuit Breaker

In a single break BOCB, there is only one fixed contact and one moving contact. During a fault current, the moving contact pushes backward, generating an arc extinguished by the compressed gas within the oil. As the name suggests, there is only one break between the contacts.

Double Break Bulk Oil Circuit Breaker

In a double break BOCB, there are two fixed contacts and one moving contact. The fixed contacts are fixed to the tank at both ends, connected to the live conductors, while the moving contact can move upward and downward using an insulating rod.

Under normal conditions, the moving contact is pushed upward to establish contact at both ends with the fixed contacts. In fault conditions, the moving contact is pulled downward to break the contacts, generating arcs at both ends. This way, the arc is split into two parts with lower strength, easily cooled off and quenched inside the oil.

Advantages:

- The oil used for arc quenching has very high dielectric strength.

- The oil insulates the live contacts from the earthed parts.

- The oil produces hydrogen gas with the heat from the arc, beneficial for arc quenching.

- The pressure of oil compresses the gas to deionize the medium.

- The gas also aids in cooling the medium.

Disadvantages:

- The oil is inflammable and poses a fire hazard.

- The contacts can get damaged by the arc.

- Carbonization of the oil from the contacts reduces its dielectric strength.

- Regular checking and maintenance of contacts and oil are required.

- The use of a large amount of oil increases costs.

- Large oil-filled tanks are heavy and occupy significant space.

- Minimum Oil Circuit Breaker (MOCB)

To mitigate the fire hazard associated with the use of a large amount of oil in BOCB, the Minimum Oil Circuit Breaker (MOCB) employs significantly less oil. In MOCB, oil is used solely for arc quenching and not for isolating live parts from earthed parts.

MOCB consists of two chambers: the arc chamber and the supporting chamber. The arc chamber, made from porcelain encased with bakelized paper, is filled with insulating oil and used for arc quenching. It contains fixed and moving contacts.

The supporting chamber, made from porcelain mounted on top of a metal chamber, isolates the arc chamber and supports it by being mounted on top. This chamber is also filled with oil used only for insulation.

The moving contact moves upward and downward with the help of a fixed arm in the supporting chamber. The moving contact has a fixed piston used to force the oil upwards, aiding in quenching the arc.

Under normal conditions, the lower moving contact establishes a connection with the upper fixed contact. In fault conditions, the arm pulls the moving contact downward, generating an arc. This arc is extinguished by the pressurized gas in the oil surrounding it and by pushing the oil from the support chamber with the help of the piston. As the contact moves downward, a vent becomes available for the hydrogen gas to exhaust.

In terms of venting, MOCB is divided into two types:

Axial Venting MOCB: Arc chamber vents are designed to allow cool oil to move in from the lower vent when moving contacts slide downward, sweeping the arc in an axial direction through the upper vent. Axial venting generates very high pressure, offering high de-ionization capabilities and consequently high dielectric strength of the oil. It is used for low current at high voltages.

Radial Venting MOCB: In radial venting MOCB, vents are designed radially along the arc chamber, causing the arc to sweep radially through multiple vents. Radial venting has low pressure, resulting in the oil having low dielectric strength. Therefore, radial venting MOCB is used for high current at low voltages. A combination of both axial and radial venting is used inside a single MOCB to efficiently break both low and high voltages.

Advantages:

- Requires a very small amount of oil.

- Low risk of fire hazard due to less oil usage.

- Light in weight.

- Small size and occupies less

Oil Impulse Circuit Breaker

In the aforementioned Minimum Oil Circuit Breakers (MOCBs), pressure is generated by the arc, dependent on the arc current, making them unsuitable for low current arc quenching. The Oil Impulse Circuit Breaker is a type of MOCB where external mechanical means, utilizing a piston connected with the moving contact, generate the necessary pressure. This method is independent of fault current and uses significantly less oil than conventional MOCBs. It can extinguish the arc regardless of its current and voltage.

Oil-less Circuit Breaker

This category of high voltage circuit breakers does not utilize oil as an arc-quenching medium. Various arc-quenching mediums can be employed instead of oil, leading to different types of oil-less circuit breakers:

- Air Circuit Breaker

- Air Blast Circuit Breaker

- SF6 Circuit Breaker

- Carbon Dioxide Circuit Breaker

- Vacuum Circuit Breaker

Air Circuit Breaker (ACB)

An Air Circuit Breaker (ACB) is a type of high-voltage oil-less circuit breaker that utilizes air as its arc-extinguishing medium. It is employed for short circuit and overcurrent protection up to 15KV and 800 to 10K Amps. ACBs are preferred over oil circuit breakers due to the absence of inflammable oil and the associated fire hazards.

The primary objective of a circuit breaker is to safely extinguish the arc and prevent arc re-striking. To achieve this, the arc voltage must be increased (minimum voltage required to maintain the arc). ACB utilizes air as a medium to extinguish the arc, employing various methods such as cooling the arc, increasing the arc length, splitting the arc, and air blasting.

In ACB, two pairs of contacts are present: main contacts (made of copper) and arcing contacts (made of carbon). Under normal conditions, the main contacts supply current, and during a fault condition, the main contacts open while the arcing contacts remain closed.

ACB is further categorized into the following types:

- Plain Air Circuit Breaker

- Arc-Chute Circuit Breaker

- Magnetic Blow Out Circuit Breaker

- Air Blast Circuit Breaker

Plain Air Circuit Breaker

A Plain Air Circuit Breaker is the simplest air circuit breaker, also known as a cross blast circuit breaker. It features a chamber surrounding the main contacts called the arc chute, made from refractory material with multiple small compartments separated by metallic plates. These metallic separators act as arc separators, dividing the arc into small arcs to increase the voltage required to maintain the arc. The air sweeps the arc upwards, causing it to cool off, and the arc is extinguished at zero current. It is suitable for low voltage applications.

Air Chute Air Break Circuit Breaker

This type of air circuit breaker has two types of contacts: main contacts and arcing contacts. The main contacts are made from silver-plated copper to reduce resistance, while the arcing contacts are made from a copper alloy with high heat resistance. Under normal operation, both contacts are closed, with the main contacts conducting current. When the main contacts open, the current diverts through the arcing contacts. Afterward, the arcing contacts open, establishing and extinguishing the arc. The arcing contacts are easily replaceable in case of wear and tear.

Magnetic Blowout Air Circuit Breaker

This type of air circuit breaker features a blowout coil that generates a magnetic field, deflecting the arc into the arc chute to extend its length and cool it. The arc is extinguished inside the breaker. The magnetic field does not directly extinguish the arc but deflects it, and the air later extinguishes it. It offers control over the arc to increase its voltage. These circuit breakers are used for up to 11KV.

Air Blast Circuit Breaker

An Air Blast Circuit Breaker (ABCB) utilizes a blast of compressed air for arc interruption. The air is stored and compressed in a tank, released through a nozzle at a very high speed to extinguish the arc. ABCBs have a high voltage capacity of up to 450KV and are used for 220KV lines in switchyards.

The Air Blast Circuit Breaker is further divided into four types:

- 1. Axial Blast Air Circuit Breaker

- 2. Axial Blast with Sliding Moving Contact ACB

- 3. Radial Blast Air Circuit Breaker

- 4. Cross Blast Air Circuit Breaker

Axial Blast ACB

In Axial Blast ACB, the air blast flows axially in the same direction as the arc. The air blast lengthens and cools the arc while increasing the dielectric strength of the medium, preventing the arc from re-striking. The moving contact, under spring force, is in a closed position with the fixed contact. The compressed air is stored in the tank below it. During a fault condition, the compressed air is released, pushing the spring to pull the moving contact, opening the nozzle orifice in the fixed contact. The arc is established between the contacts, lengthened, and cooled by the blast of air flowing through the orifice. This entire process occurs simultaneously, and the arc is extinguished.

Axial Blast ACB with Sliding Moving Contact

This type of breaker is a modified form of the axial blast ACB, featuring a horizontally fitted moving contact on a spring with a piston. The fixed contact has a nozzle orifice blocked by this moving contact. It operates similarly to the previously discussed ACB in terms of arc quenching.

Radial Blast ACB

In Radial Blast ACB, the contacts are hollow like a tube, providing free space inside both the moving and fixed contacts. This free space allows compressed air to flow and cool the arc. The radial blast of air flows radially inside the contacts along the arc, earning it the name radial blast ACB. During a fault condition, the arc is formed between the contacts when they separate. The radial blast of air cools off the arc, increases the dielectric strength between the contacts, and extinguishes the arc at zero current.

Cross Blast ACB

In Cross Blast ACB, the air blast is directed at a right angle to the arc. The air blast deflects and lengthens the arc into the arc chamber, where arc splitters split and lengthen the arc to extinguish it. There is an exhaust in the arc chamber for the air to flow out. The air tank is fixed perpendicular to the movement of the contacts. During a fault condition, the contacts open, and the arc is established. Simultaneously, the air blast is released, sweeping the arc into the arc chamber. The arc splitters split the arc, which is eventually quenched at zero current. The air blast also increases the dielectric strength of the medium between the contacts, preventing the arc from re-striking.

Advantages of ACB:

- ACB does not have any fire hazards, unlike oil circuit breakers.

- ACB has very high speed, with rapid arc quenching.

- The speed of arc quenching remains the same for all values of current.

- ACB has a small size due to the minimal space required for an air blast to cool and quench the arc.

- It is suitable for frequency operations, where circuit breaking and making occur frequently, such as in switchyards.

- ACB is very reliable and consistent because of the short arcing time, which does not wear the contact quickly.

- It requires less maintenance due to the reduced wearing of the contacts.

- ACB is relatively cheaper, as air is used as the arc-quenching medium.

Disadvantages of ACB:

- The air compressor needs maintenance to maintain correct pressure at all times.

- The air compressor takes up significant space.

- There is a possibility of a high rate rise of re-striking voltage and current chopping.

- Air pipes junctions may leak air pressure.

- The air release produces noise.

- Air, compared to other insulating gases, has lower extinguishing properties.

Sulphur Hexafluoride (SF6) Circuit Breaker

_circuit_breaker.webp)

Sulphur Hexafluoride, or SF6, is a non-flammable and insulating gas with very high electronegativity. It has a strong tendency to absorb electrons and forms negative ions, which are heavier than free electrons. When an arc is struck between the contacts, the medium is ionized, and SF6 absorbs the free electrons, forming negative ions that enhance the dielectric strength of the medium. SF6 has superior insulating and arc-quenching capabilities compared to air, approximately 100 times better.

SF6 is expensive and a greenhouse gas. Although SF6 itself is not toxic, its product gases are toxic, and its emission is environmentally hazardous. Therefore, a closed circuit gas system is designed for such breakers, where SF6 gas is reused after each operation. The system also monitors its pressure, directly proportional to its dielectric strength.

There are three types of SF6 Circuit Breakers:

- Non-Puffer Type SF6 Circuit Breaker

- Single Pressure Puffer Type SF6 Circuit Breaker

- Double Pressure Type SF6 Circuit Breaker