Battery Desulfator: How It Works & Why It Matters

What is a Battery Desulfator?

The Science Behind Battery Sulfation

Battery sulfation is a chemical reaction that takes place in lead-acid batteries when the lead sulfate crystals are developed and appear hard on the lead plates of the battery. Under normal working conditions, the lead sulfate is generated in the process of battery discharge. However, in the charging process, the product is converted to active materials in a healthy battery. As the battery remains in a semi-charged state during a prolonged period of time, lead sulfate crystals become hard and develop a layer of insulation around the plates. This coating reduces the conductive potential of the battery and decreases its power and energy storage potential and causes the battery performance to slowly reduce.

Definition of Battery Desulfator

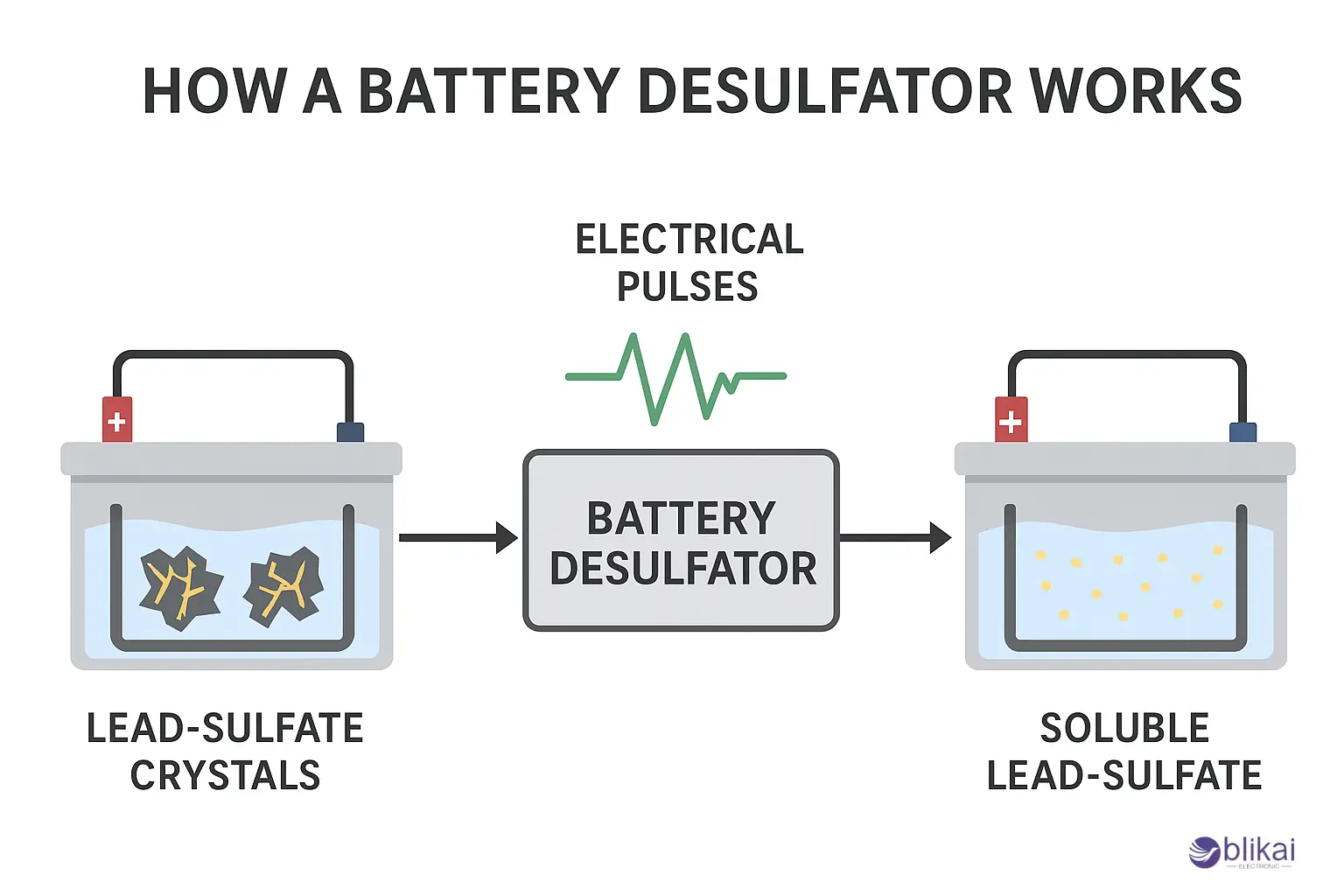

A battery desulfator is a special equipment that is used to fight against the sulfation effect in lead-acid batteries. It operates by directing accurate electrical impulses or high-frequency signals into the battery that dissolve hardened lead sulfate crystals on the battery plates. This is done to stabilize the chemical balance within the battery so that it can store and provide more power. There are many types of battery desulfators, from small portable ones to larger battery banks and integrated systems, and they can be applied to automotive batteries, marine batteries, solar power systems and other lead-acid battery applications.

Benefits of Using a Desulfator

The use of battery desulfators is appreciated because of their capacity to prolong the battery life and increase efficiency. They will mitigate permanent damages that might otherwise be caused by sulfation, thus it will take batteries to be replaced. They are especially applicable to the batteries that tend to undercharge or spend a lot of time being idle, like in boats, RVs, solar, or standby power systems. In addition to enhancing the performance of batteries, the desulfators minimize the number of charging times and perfect the battery capacity. This means a lot of savings in cost and increased reliability in the long run of users.

Types of Battery Desulfators

Pulse-Type Desulfators

There are a variety of designs and battery desulfators designed to meet the requirements of a variety of needs and battery types. The pulse-type desulfator is the most widespread, and it applies regular high-frequency pulses to the battery. The pulses disintegrate hardened lead sulfate crystals without causing any impact to the normal charging of the battery. Pulse-type desulfators are commonly small, inexpensive, and simple to install, so they are popular on car batteries, motorcycles, and other small marine installations. They can be used and maintained on a daily basis; they are especially so when there is a tendency to undercharge or leave batteries not used over an extended period of time.

Smart Desulfators

The other one is the smart desulfator, which uses sophisticated technology like the use of microprocessors to detect the battery status in real-time. These computers automatically change the frequency and strength of the pulse, according to the degree of battery charge and sulfation. Smart desulfators are more effective in the treatment of severe sulfation and can be adjusted to the types of batteries such as a deep-cycle and industrial battery. Their smart work guarantees a better desulfation process and better long-term optimization of battery health, so they are applicable to high-value battery systems, like renewable energy storage or fleet vehicles.

Multi-Battery Desulfators

Multi-battery desulfators are also available, which are designed to operate with battery banks instead of a single cell. Such units can be used in solar power systems, RVs, boats, and backup power systems. They are able to service multiple batteries at the same time, take care of performance equality, and avoid sulfation throughout the bank. Multi-battery desulfators are frequently equipped with monitoring capabilities that monitor the status of every battery in real-time and enhance efficiency in the maintenance process.

How a Battery Desulfator Works

The Chemistry of Sulfation and Desulfation

Sulfation in the case of lead-acid batteries results in the deposition of crystals of lead sulfate on the battery plates as a result of undercharging or extended discharge. These crystals become hard with time, making the chemical reactions involved unable to take place, making the battery work efficiently. This is reversed by a battery desulfator that applies controlled electrical pulses to the battery. These pulses provide brief bursts of high-frequency energy, which rupture the hardened sulfate crystals to form a soluble form. Through the process, the battery is replenished with the active material and the capacities and efficiency of the battery are restored.

Pulse Technology Explained

The vast majority of battery desulfators operate on the basis of pulse technology, creating short and high-frequency pulses of electricity. Such pulses are measured in microseconds, and they are directly connected to the battery sides. The pulses are of high frequency and will produce a physical and chemical response in the battery that will interfere with the crystalline structure of lead sulfate, but will not damage the plates in the battery. This enables the sulfate to revert to the original state in the electrolyte. More developed desulfators also adjust pulse width and amplitude according to battery conditions, and work out the optimum desulfation. Pulse technology is very efficient as it does not require very many charging cycles and high temperatures, thus it is safe when it comes to the maintenance of the battery over a long period.

Smart Desulfation Systems

The vast majority of battery desulfators operate on the basis of pulse technology, creating short and high-frequency pulses of electricity. Such pulses are measured in microseconds, and they are directly connected to the battery sides. The pulses are of high frequency and will produce a physical and chemical response in the battery that will interfere with the crystalline structure of lead sulfate, but will not damage the plates in the battery. This enables the sulfate to revert to the original state in the electrolyte. More developed desulfators also adjust pulse width and amplitude according to battery conditions, and work out the optimum desulfation. Pulse technology is very efficient as it does not require very many charging cycles and high temperatures, thus it is safe when it comes to the maintenance of the battery over a long period.

Additional Benefits of the Desulfation Process

The desulfation process has other advantages to the performance of a battery besides eliminating the sulfate accumulation. It increases capacity retention, reduces internal resistance and improves charge acceptance by restoring chemical balance. This implies that not only are batteries long-lasting, but they also provide more constant power output. Moreover, desulfation is able to enhance performance in cold weather, decrease charging duration, and eliminate unexpected battery failures. Battery desulfators are a necessary maintenance tool in applications where there is a significant need to ensure reliability, e.g., in emergency backup systems or in the storage of renewable energy.

How Long Does It Take for a Battery Desulfator to Work?

The duration of time that the battery desulfator takes to display results also greatly depends on the status of the battery itself. A slightly sulfated battery can be expected to improve after just a couple of days, as the pulse technology draws the crystal grains of sulfate off the surface. Conversely, a very sulfated or an old battery can require weeks, or even months of constant desulfation before the results become evident. With extreme cases, the battery might be past the point of use, hence even long periods of desulfation will not reclaim the performance of the battery.

Influence of Usage and Charging Patterns

The battery desulfators are usually effective when used alongside normal charging. As an example, desulfation may occur faster in a battery in an automotive or marine alternator battery where the battery is regularly charged by the alternators or onboard chargers. By comparison, stationary batteries or those in a backup system are idle most of the time and therefore can require longer to recover as the chemical reactions are slower. Regular maintenance, correct charging habits, and maintaining the battery in accepted voltage limits will accelerate the desulfation and improve the chances of total recovery.

Realistic Expectations for Results

Desulfators are useful, but one should not have too high hopes. Such devices are not one-second solutions and cannot bring back to the condition of a like-new battery every damaged one. Rather, they slowly adjust the chemical balance, reduce internal resistance and increase charging acceptance. The majority of users note that the effects can be seen after 2 to 8 weeks of constant use, depending on the severity of the sulfation and the type of battery. Desulfation is a maintenance procedure as opposed to a speedy repair plan. Desulfators, when used aggressively, can increase the life of a battery and counter sulfation-induced breakdowns before they can get serious.

Conclusion

Battery desulfators are playing an ever more significant role in contemporary energy management. Their capacity to reestablish chemical equilibrium, optimize charge uptake and minimize internal resistance makes them essential in the automotive and marine industry as well as renewable energy storage and backup power systems. Desulfation is not a direct solution and can not resuscitate all degraded batteries, but it is an extremely effective preventative and maintenance technology. To individuals and professionals with a consistent battery performance requirement, the use of desulfators within the normal care is a technical and financial benefit.

FAQ

How long does a battery desulfator take to work?

It depends on sulfation severity—days for light cases, weeks or months for heavy buildup. Regular charging speeds recovery, but the results aren’t instant.

Can a battery desulfator fully restore a dead battery?

No. Desulfators improve sulfated batteries but can’t fix physically damaged or completely dead batteries. They work best for maintenance and extending battery life.

Are battery desulfators worth it?

Yes. They extend battery life, improve performance, reduce replacements, and offer savings—especially useful for vehicles, marine, and renewable energy systems.

Some images are sourced online. Please contact us for removal if any copyright concerns arise.