NMC Battery vs. LFP Battery: A Detailed Comparison

What is an NMC Battery?

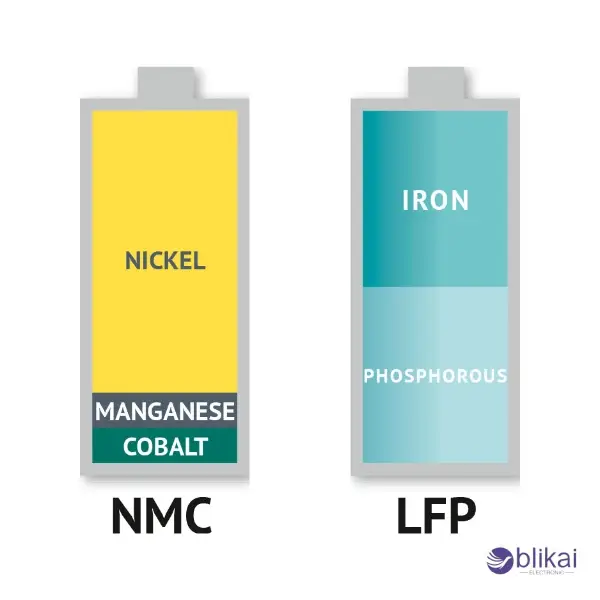

An NMC battery, also known as nickel-manganese-cobalt (NMC) with Nickel, Manganese and Cobalt as a mix as the cathode. These batteries find their uses in the high-performance segment of the electric vehicles (EVs), renewable energy storage devices and consumer electronics. The batteries made by the NMC are of high-energy density, have long cycle life and are thermally stable; therefore, they can be very helpful in driving the high-energy requirement appliances, particularly in the area of automotive and energy storage.

Composition and Role of Materials in NMC Batteries

Ni is requested to provide the majority of the battery energy, and this is why it is very helpful in any type of application that requires a high-energy density, such as EVs. Manganese (Mn) is employed in the stabilization of the battery that provides the battery with structural stability, besides improving thermal stability and therefore prolonging the battery life and improving safety. Finally, Cobalt (Co) assists in the process of raising the energy density and the life cycle of the battery.

What is an LFP Battery?

A Lithium Iron Phosphate (LiFePO₄) battery cell is referred to as an LFP battery cell. This chemistry has several benefits over other lithium-based batteries, especially in safety, economic considerations and life cycle. LFP batteries are made of iron and phosphate as the material constituents, which are easier and cheaper to get than cobalt and nickel, unlike Nickel Manganese Cobalt (NMC) batteries that are more widely deployed. LFP batteries are also applicable in applications that require safety, long life and low cost since it has stable and strong chemistry. One such application is with the electric vehicles (EVs) or the energy storage systems.

Composition and Role of Lithium Iron Phosphate

Lithium Iron Phosphate (LiFePO₄) is the most important part of an LFP battery and a cathode material. The lithium ions between the cathode and anode result in charge and discharge reactions of the battery, which are the cause of its energy storage capability. It is due to the fact that iron (Fe) is inert, and it does not have a high probability of overheating as compared to other materials that are used to make lithium batteries, which makes it very important in stabilizing and making lithium batteries safe. Phosphate (PO₄) is also an important constituent that increases the thermal stability of the battery, and thus, the reason why the LFP battery is less likely to experience thermal runaway. This composition constitutes a battery, which is safer, longer-lasting, and less expensive as opposed to others.

Performance Comparison: NMC Battery vs. LFP Battery

Energy Density

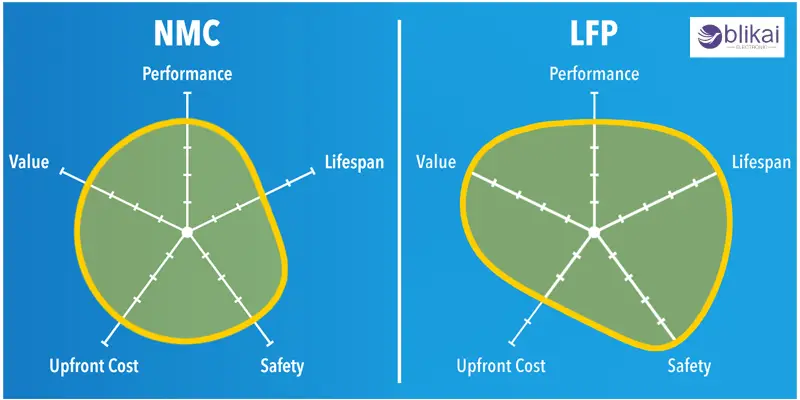

The NMC batteries are characterized by a high energy density, or rather, they will hold more energy in mass or volume. This has made them the best in those applications where distance is of the essence, like electric vehicles (EVs). The increased energy density of NMC batteries is translated into the more effective utilization of space and extended driving ranges with one charge. This has made NMC the place to be when it comes to quality electric vehicles like Tesla and BMW, whereby consumers treasure the range and performance of the vehicles. LFP batteries, in fact, are lower in terms of energy density, which refers to the inability to store as much energy in the same area. This makes LFP batteries inappropriate for anything to do with long-range operation, but they are generally predictable and inexpensive, which makes them a good fit with budget EVs and energy storage systems, where energy density is not such a concern.

Charging Speed

The speed of charges is a feature of the batteries of NMC and thus, it can be charged within the shortest possible period, in some cases, it is a few hours and in others, much quicker. This makes them most appropriate in cases where time is of the essence, such as in long-range electric vehicles or when quick recharge is required. The fact that high charging currents can be operated without severely impacting the capacity is a major factor in their use in performance cars. On the other hand, LFP batteries are also reliable for charging, although they charge more slowly than NMC. However, LFP batteries have a longer cycle life and are more acceptable in cases where periodic charging or slower and lower recharge rates are acceptable.

Temperature Stability

NMC batteries tend to be more susceptible to changes in temperature that would adversely affect their functionality and safety. The presence of high temperatures might result in overheating and, worse still, thermal runaway, and this might be a safety concern. Such sensitivity means that greater care should be taken of thermal differences when working with and storing NMC batteries, especially when operating electric vehicles in regions with extreme weather conditions. On the other hand, LFP batteries are more temperature stable and extend their operating temperature to allow them to do their job more effectively at higher temperatures without the danger of overheating. They possess good thermal properties, which can help to increase the durability and safety in the long run. LFP batteries are also less susceptible to heat decay and can work at higher temperatures than NMC batteries, which makes them the optimal choice in energy storage applications in sunny areas and in applications with low maintenance where temperature extremes are frequent.

Cost Comparison: NMC Battery vs. LFP Battery

Material Costs

NMC batteries are also costlier because they contain cobalt and nickel as their cathode. Not only are these materials expensive, but they are also prone to changes in price, particularly cobalt; most cobalt is mined in highly dubious situations and in small geographical locations. Compared to LFP batteries, NMC batteries are highly expensive because of the use of rare and expensive materials, including nickel and cobalt. The LFP batteries, however, are cheaper in raw materials, and they are more available and contain Iron (Fe) and phosphate (PO₄). The materials themselves are also very easily accessible, and this, among others, makes it cheaper, therefore making materials in LFP batteries cheaper. The LFP technology thus has lower material costs that might be quite beneficial when it must be applied on a very large scale, such as in mass-market EVs or in energy storage plants.

Manufacturing Costs

The production of NMC batteries is relatively costly and more difficult than LFP batteries. The production of NMC involves a keen processing and blending of several metals, such as cobalt and nickel, which makes the production process more complicated and expensive. The exact process of control required to make sure that these materials are mixed properly and have the required level of chemical stability makes the production cycle more costly and time-consuming. Moreover, the supply of these materials is also reduced in most cases, which increases the cost of production even more. Conversely, LFP batteries have an easier and cheaper manufacturing procedure.

Overall Cost Efficiency

Though it costs NMC batteries more in the initial stages since the materials and manufacturing are a costly procedure, it has a higher energy density and hence may result in superior performance in some applications. As an illustration, the NMC batteries used in electric vehicles have a higher driving range and faster charges, which could be rewarded with the increased initial cost by the consumer, who intends to use the vehicle based on its performance and range. Nevertheless, LFP batteries have an attractive long-term value, particularly in applications where energy density is not as important. Although LFP batteries have a lower initial cost, they do well with respect to their life cycle and safety, with their longer life cycle and low maintenance requirement. Although NMC might be the superior option when it comes to high-performance or a high-energy-consuming application, LFP can be a more affordable alternative to budget-friendly consumers and companies that require long-term, cost-effective and reliable energy supply.

Which Battery is Best for Your Needs?

NMC Battery

A battery based on NMC is frequently more preferable when maximum performance and energy density are the most important criteria. The fact that it can store more energy within a smaller area, it is especially good at long-range electric vehicles (EVs) where the range over a single charge is a significant selling point. That is why NMC batteries are still popular among many prestigious car makers, and they use them in their flagships with EVs.

LFP Battery

The LFP battery can be better than the other options in a situation where the key factors are safety, affordability, and long-term durability. Having a significantly increased cycle life and thermal stability, LFP batteries are best used with low-cost EVs, where maximum range is not desired but rather the ability to carry out daily transportation at a reduced price. They are also suitable for home energy storage systems, particularly when they are used in conjunction with solar panels, since they can undergo thousands of cycles without significant depreciation. In addition, the LFP batteries can be applied in industries and businesses because they will require less maintenance and longer service due to reduced safety requirements as opposed to NMC products.

Conclusion

Comparing the NMC batteries against LFP batteries, one can easily realize that both types of batteries have their strong and weak sides; hence, they are fit to address very different demands. But whatever you need, whether the high-performance of the NMC or the stability and reliability of the LFP, each of the two technologies is already making the future of electric mobility and sustainable energy storage.

FAQ

1. Which battery lasts longer, NMC or LFP?

LFP batteries usually last longer, often reaching 3.000–5.000 cycles, while NMC batteries average 1.000–1.500. This makes LFP better for long-term use in energy storage or budget EVs.

2. Are NMC batteries safe to use compared to LFP batteries?

NMC batteries have more heating problems and require sophisticated cooling mechanisms. LFP batteries are also safer and have higher thermal stability than others, hence home storage-friendly and cost-effective EVs.

3. Why do some EV makers choose NMC while others prefer LFP?

Premium EVs use NMC for a higher range and faster charging. LFP is chosen for budget EVs and storage systems because it’s cheaper, safer, and lasts longer.

Some images are sourced online. Please contact us for removal if any copyright concerns arise.

6V Battery vs 12V Battery: Features, Applications & Performance

Automotive Battery Guide: 24F Battery vs 27F Battery Explained

SR927W Battery Guide: Specs, Equivalents, & Replacement

18350 Battery: Size, Applications, & Comparisons

E90 Battery Guide: Specs, Applications& Equivalents

51R Battery: Size, Compatibility, & Applications

CR2430 Battery: Features, Lifespan & Replacement Guide

14500 Battery Explained: Features, Comparison & Lifespan

A23 Battery: Applications, Equivalents, Lifespan, & Key Differences

The Complete U1 Battery Guide: Types, Variants, & Applications