Battery Management System Guide: Functions, Circuits & Components

Introduction to Battery Management Systems (BMS)

A Battery Management System is an electronic control device that is at the heart of monitoring, protecting, and optimization of rechargeable battery packs in EVs, energy-storage systems and portable electronics. The BMS offers a regulation of the voltage and current and the temperature change of each cell since the lithium-ion batteries are vulnerable to these things, as well as to increase the life of each cell and reliability, not to mention their efficiency in terms of energy. The BMS is important in contemporary power systems by regulating the charge and discharge conduct, matching cells, and communicating with other external devices.

Core Functions of a Battery Management System

Battery Monitoring

The basic operation of any Battery Management System is battery monitoring, which provides real-time measurements of cell voltage, pack voltage, charging current, discharging current, and internal temperature. These measurements enable the system to identify abnormalities at the early stage and make changes in the control strategies, which would assure safe operation. Correct monitoring has also ensured that BMS can maintain consistent performance at varying loads and environmental conditions.

Protection and Safety Control

A Battery Management System has protection circuits that guard against unsafe states, including overcharging, over-discharging, overcurrent, short circuit and thermal runaway. BMS interrupts the pack in case of exceeding the thresholds and avoids permanent damage or safety accidents. By controlling MOSFET switches or relays, the BMS ensures the battery stays within its safe operating area (SOA), especially during aggressive load changes or fast charging.

Cell Balancing

Cell balancing equalizes the voltage and state-of-charge (SOC) of all cells in a multi-series battery pack to avoid imbalance-related problems. Passive balancing can be used to dissipate energy on higher-charged cells using resistors, whereas active balancing can be used, which involves transferring energy between cells using capacitors or inductors. Balanced cells guarantee an increase in usable capacity, better cycle life and stability of the pack when using high-power applications.

State Estimation (SOC, SOH, SOP)

State estimation algorithms determine the battery’s remaining charge (SOC), long-term health (SOH), and available power output (SOP). Common techniques include Coulomb counting, open-circuit voltage modeling, Kalman filtering, and impedance-based estimation. These algorithms allow the BMS to provide accurate energy predictions, control charging behavior, and optimize long-term system performance.

Communication & System Coordination

Contemporary Battery Management Systems interface with chargers, vehicle control units, inverters, and monitoring devices by CAN, UART, SMBus, RS485 or Modbus. The coordinated charging, load control, diagnostic reporting, and safety-important shutdowns are guaranteed by the reliable communication. Remote monitoring in energy-storage and industrial systems can also be done using communication protocols.

BMS Architecture & Circuit Design

Basic BMS Block Diagram

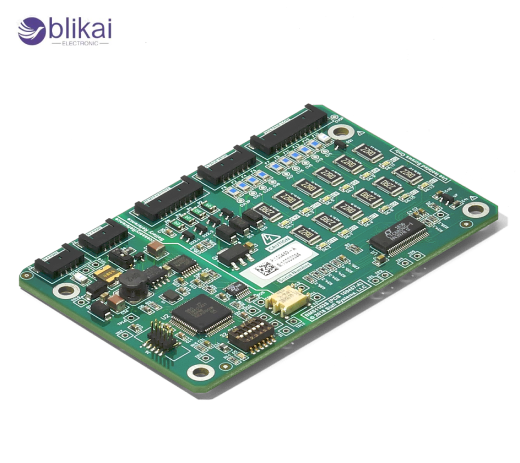

A Battery Management System normally comprises sensing circuits, analog front-end ICs, a microcontroller, balancing circuits, protection MOSFETs and communication modules. They are used to combine these blocks to measure cell conditions, execute algorithms, activate safety controls, and communicate with external equipment. The block diagram gives a top-level architecture of the design or analysis of any BMS.

BMS Hardware Circuits

BMS hardware starts with voltage-sensing dividers for each cell, followed by current-sensing elements such as shunt resistors or Hall-effect sensors. Temperature monitoring is handled by NTC or PTC thermistors placed strategically across the pack. Protection circuits rely on MOSFET pairs or relays, while fuses add redundancy. This use of circuits provides accurate electrical feedback and enables the microcontroller to carry out accurate control.

Power Topology Options

The battery Management Systems are different depending on the pack architecture. Single-cell BMS units are more basic in protection, whereas multi-series packs are more complex to balance and monitor. High-voltage EV BMS designs use modular or distributed architectures, improving safety and scalability. Centralized BMS units place all circuitry on one board, while modular systems use multiple cell-monitoring units (CMUs) connected to a master control unit (MCU).

Key BMS Components Explained

Battery Monitoring ICs / AFE ICs

Analog Front-End ICs measure voltage, temperature, and current across all cells with high precision. They integrate ADCs, reference circuits, and sometimes balancing drivers. Popular models offer daisy-chain communication for high-voltage applications and greatly simplify BMS design.

Microcontrollers & Processors

The microcontroller does SOC, SOH, SOP, balancing control, data logging, and communication protocol management computations. It processes sensor data and computes safety-critical logic. The EV BMSs of the higher end might be based on dual-core processors to provide redundancy and safer operation.

MOSFETs & Protection Switches

MOSFETs act as high-current switches that allow or block charging and discharging paths. System requirements are dependent on the low-side or high-side configuration. EV systems can be based on either contactors or automotive-grade relays, whereas portable equipment can take the form of dual-MOSFET-based protection.

Balancing Resistors & Inductors

Passive balancing uses resistors to discharge cells with higher voltage levels. Active balancing relies on inductors or capacitors to transfer energy between cells with minimal loss. The component selection directly impacts balancing efficiency and thermal performance.

Temperature Sensors

Thermistors are used to measure battery temperature with high accuracy. NTC sensors are common in lithium-ion packs, while PT100 or integrated silicon sensors are used in industrial and high-voltage systems. Proper placement ensures fast thermal detection.

Communication Interfaces & Connectors

CAN transceivers, RJ45-style connectors, and high-current bus bars link the BMS with external modules. These elements offer soundproof communication and understandable mechanical and electrical connections.

BMS Types & Application Categories

Lithium-Ion BMS

Electric vehicles, power tools, drones and medical devices, as well as portable electronics, use Lithium-ion Battery Management Systems. They are also concerned with high energy density, fine voltage regulation, and rigid thermal safeguards. Expert units are compatible with rapid charging and prolonged cycle periods.

Lead-Acid BMS

Lead-acid batteries require less complex functions of BMS since they can survive in a broader range of voltages, and their energy density is lower. Typical systems monitor voltage, temperature, and state-of-charge to prevent sulfation and overcharging in UPS and automotive applications.

High-Voltage EV BMS

The automotive high voltage BMS systems consist of cell-monitoring units, a master control unit and isolation measurement circuits. They operate hundreds of cells in series; they can be subjected to high current loads; and they have to satisfy high standards of automotive safety, including ISO 26262.

Energy Storage System (ESS) BMS

ESS Battery Management Systems will be used in grid-scale batteries in solar storage, wind farms and backup power. They concentrate more on stability over a long duration, fault-detection, remote communication and redundancy of the system, to ensure that the system does not cease to operate.

How to Select a Battery Management System

To choose a BMS, one needs to match the system with the pack voltage, number of series cells and continuous and peak current rating. Communication interfaces, features of protection available, balancing type, and application environment are also factors that should be taken into account by designers. UN38.3, UL 1973, IEC 62619 and automotive safety ratings are some of the key certifications that signify reliability. The right BMS provides optimum performance and safety of the targeted system.

Common BMS Problems & Troubleshooting Tips

Common issues include cell imbalance, inaccurate SOC readings, overheating, and protection triggers caused by wiring errors or sensor faults. Troubleshooting begins with checking voltage measurement consistency, ensuring good thermistor placement, verifying shunt calibration, and reviewing firmware thresholds. Protocol mismatch, grounding issues or wiring noise can also be shown by communication errors. The majority of the issues can be addressed by means of recalibration and configuration.

Summary

Modern rechargeable batteries cannot operate safely, reliably, and with high performance without a Battery Management System. The BMS can monitor, protect, balance, and communicate in a single control unit to maximize the battery life of different applications such as EVs, ESS, and portable electronics. The research on BMS operations, circuits, and components allows making improved design decisions and promotes the safety and efficiency of the system.

What additional functions can a modern BMS provide?

A modern BMS can also manage contactors, monitor isolation, and record event logs for diagnostics. It supports battery passport data, fault history, and pack-level safety actions. These features improve system reliability in EVs and ESS systems.

How does a BMS handle thermal management beyond temperature sensing?

A BMS can control active cooling/heating, adjust charge/discharge limits, and detect thermal runaway risks. It works with fans, liquid cooling, or heaters to keep cells in a safe temperature range.

Does a BMS estimate more than just SOC?

Yes, modern BMS also estimates SOH and SOP, showing battery health and available power. It records historical data for aging prediction and maintenance planning.

What BMS architectures exist beyond centralized designs?

Large battery packs often use modular or distributed architectures. Each module has a CMU, connected to a main BMU for high-voltage systems. Daisy-chain or isolated communication improves safety and scalability.

Why is isolation monitoring important in high-voltage BMS?

Isolation monitoring makes sure that the HV battery is safe compared with the chassis and low low-voltage system. It eliminates the chances of shocks, it identifies insulation failures at early stages, and it initiates protective shutdown.

How does a BMS contribute to long-term battery health?

It tracks degradation trends, logs abnormal conditions, and optimizes charging to reduce stress. These functions extend battery lifespan and improve system safety over time.

Some images are sourced online. Please contact us for removal if any copyright concerns arise.

L736 Battery Equivalent: Compatible Alternatives You Should Know

LR626 Battery: Specifications, Applications & Replacements

371 Battery: Applications, Specifications & Replacements

CR927 Battery: Types, Applications & Lifespan

Battery Isolator for Dual Battery Electronic Systems

What Is a 392 Battery? Applications, Equivalents & Differences

LR14 Battery Guide: Applications, Specs, Lifespan & Troubleshooting

What is Battery Monitor & How to Use It

48V Battery: Power, Efficiency & Applications

21700 Battery: Power, Performance & Applications