How Do NTC Thermistors Work? A Key Role in Inrush Current Suppression

Introduction

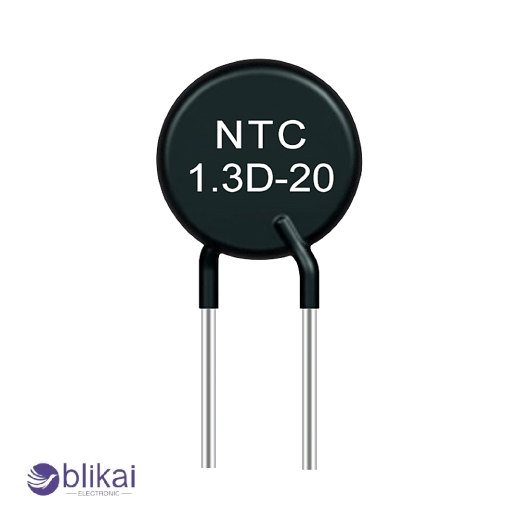

Electrical and electronic systems must often be guarded against sudden problems that might harm their efficiency or the parts within them. A common issue is inrush current which means a sudden rush of current entering a device when it is turned on. As a consequence, circuit breakers could be tripped by sensitive parts that become damaged. Fortunately, an inexpensive and compact NTC thermistor is available as a convenient solution to this problem.

NTC thermistors are commonly used in power supply units, motor drives, battery chargers, LED drivers and many other electronic circuits as a way to control inrush current. We will take a close look at how NTC thermistors function, what makes them unique, their part in suppressing inrush current and why they are important in today’s electronics.

What is an NTC Thermistor?

NTC thermistors are resistors whose resistance level drops as they get hotter. The way NTC thermistors’ resistance decreases with temperature makes them useful in temperature measurement and current control.

Key Characteristics:

Resistance vs. Temperature: With less heat, NTC thermistors form strong resistance. As heat spreads inside, their appearance is dangerously weaker and more transparent.

Material Composition: Most NTC thermistors are developed by sintering materials such as manganese, cobalt and nickels into ceramic forms.

Form Factors: Optoelectronics are available in various forms, including discs, beads, chips, and surface-mount devices, making it easy to integrate them into different designs.

NTC vs. PTC Thermistors:

Applying heat to PTC thermistors increases their electrical resistance in a manner opposite to that of NTCs. Most PTCs are chosen for overcurrent protection, and NTCs are popular for limiting the surge of current and measuring temperature.

How Do NTC Thermistors Work?

NTC thermistor operation is driven by a trait known as the negative temperature coefficient of semiconductors.

Resistance-Temperature Behavior:

Cold Start: When an NTC thermistor is first energized, it is cool and has a high resistance. This high initial resistance limits the current flowing into the circuit.

Self-Heating: Power wasted through voltage flowing through the thermistor creates additional heat.

Resistance Drop: Because its resistance is lower due to the higher temperature, standard amounts of current can travel with little drop in voltage.

This behavior makes NTC thermistors a self-regulating component. They adjust their resistance dynamically, providing high resistance during startup and low resistance during steady-state operation.

Graphical Insight:

A plot of resistance vs. temperature for an NTC thermistor reveals an exponential decay curve—steep at first and gradually leveling off, indicating faster resistance changes at lower temperatures.

Understanding Inrush Current

A good starting point is to understand what inrush current is and what difficulties it causes before moving on to NTC thermistors.

What is Inrush Current?

Inrush current occurs when an electrical device is first powered up and begins to draw a sudden, high current. You can experience this surge as:

5 to 10 times higher than the steady-state current

Short, but still powerful enough to damage components

Causes of Inrush Current:

Charging of large capacitors in power supplies

Magnetizing inductance in transformers

Motor startup current spikes

Sudden connection to a low-impedance power source

Problems Caused by Inrush Current:

Component Stress: Sudden high currents can cause degradation or destruction of ICs, capacitors, or contacts.

Circuit Breaker Tripping: Safety devices may activate unnecessarily due to false overcurrent detection.

Reduced Efficiency: Power loss and heat generation reduce the overall efficiency of the system.

To ensure a circuit lasts, is safe, and performs well, inrush current needs to be controlled.

The Role of NTC Thermistors in Inrush Current Suppression

NTC thermistors are specifically engineered to provide effective inrush current suppression by acting as a temporary high-resistance barrier when power is first applied.

Step-by-Step Function:

1. Power-On: The circuit is turned on. The NTC thermistor, being cold, has a high resistance.

2. Initial Surge Limited: The high resistance restricts the inrush current, protecting sensitive components.

3. Self-Heating Phase: The current begins to flow through the thermistor, causing it to heat up internally.

4. Resistance Drop: As the thermistor heats up, its resistance rapidly drops to a low value.

5. Normal Operation: The circuit now operates under normal current flow with negligible resistance from the thermistor.

Typical Applications:

AC-DC power supplies: To prevent capacitor damage during startup

LED lighting drivers: To ensure a longer LED lifespan

Battery chargers: To prevent charging circuit stress

Electric motors and transformers: To avoid magnetic inrush currents

NC thermistors have become essential in both manufacturing and power technology due to their useful function.

Advantages of Using NTC Thermistors for Inrush Current Suppression

Compared to relays, timers and active current limiters, NTC thermistors are better suited for protecting an inrush current.

Key Advantages:

Cost-Effective: They are inexpensive and require no external control circuitry.

Passive Operation: No microcontroller or timing circuit is needed; they self-regulate based on temperature.

Compact Design: Small size enables use in portable or space-constrained designs.

Fast Response: Immediate resistance change on temperature rise ensures effective protection.

Long Service Life: Robust materials and simple design yield high reliability.

Though active suppression is often complex and expensive, NTC thermistors make things easy with a straightforward plug-and-use option.

Considerations When Using NTC Thermistors

Despite their advantages, careful consideration is necessary when selecting and using NTC thermistors.

Selection Factors:

Initial Resistance (R25): Must be high enough to limit inrush but low enough for normal operation.

Maximum Current Rating: Ensure the thermistor can handle the peak inrush without damage.

Steady-State Resistance: This should be low enough to prevent wasting power or affecting circuit performance.

Thermal Time Constant: Affects how quickly the thermistor responds to changes in temperature.

Ambient Temperature: High ambient temps may reduce initial resistance, affecting protection.

Disadvantages:

Thermal Recovery Time: After power-off, the thermistor requires time to cool before it becomes effective again.

Voltage Derating: Exceeding rated limits can cause failure.

Not Resettable Like PTCs: Once an NTC is overheated beyond its limits, it may fail permanently.

Proper circuit design and component derating can mitigate these issues, ensuring safe and effective operation.

Conclusion

Inrush current suppression heavily depends on NTC thermistors, which are easy to use, require no maintenance, and are very effective in safely starting electronic devices. Because they react to changes in temperature, they are able to work seamlessly through quick changes in circuit status by limiting dangerous current surges.

Because electronics need greater reliability and efficiency, the use of NTC thermistors in power supply circuits, chargers and motor controllers will not decrease.

Using NTC thermistors helps make your designs safer and stronger, making them suitable for design engineers, technicians and electronics lovers.

FAQs

Q1: What happens if an NTC thermistor fails?

A1: A failed NTC thermistor may turn into either a short circuit or an open circuit, leaving inrush current protection neglected. As a result, your electronic components may become damaged, and circuit breakers may trip.

Q2: Can NTC thermistors be used in all electronic devices?

A2: These types of thermistors are ideal for many devices that require a large current but are not suitable for those that need fast temperature readings.

Q3: How do you test an NTC thermistor?

A3: You can test it using a multimeter by measuring its resistance at room temperature and comparing it to the manufacturer’s specifications. Resistance should decrease as the thermistor warms up.

Q4: What’s the difference between an NTC thermistor and a fuse in circuit protection?

A4: The NTC thermistor controls current by becoming more resistive as it heats up, allowing it to be reused, whereas a fuse breaks the circuit and is removed when it melts.

Related Articles

Microprocessor vs Integrated Circuit:Which One Is Better

Types of Circuit Breakers: Overview and Applications

What Is a Short Circuit? Causes, Effects, and Prevention

What is the Circuit Symbol for a Multimeter? (Guide)

Inrush Current Limiter Guide: Types, Function & Applications