Inrush Current Limiter Guide: Types, Function & Applications

What Is an Inrush Current Limiter?

An inrush current limiter is used to prevent a surge of current from entering a circuit as soon as it powers up. At power-up, capacitors and inductors may require much higher amounts of current than usual. Without protection, this inrush current can harm parts inside the system, may overload circuit breakers and decrease the system’s life.

Why Is Inrush Current Limiting Important?

The initial flow of electricity in the circuit can be higher than what it becomes under steady operation. As a result of this spike, a number of things may occur:

- Damage switches, fuses, or other components.

- Reduce the lifespan of the device.

- Create electrical noise or interference.

- Trip circuit protection devices.

How NTC Thermistor-Based ICLs Work

In most cases, a power supply or other electronic equipment will use an NTC thermistor to limit inrush current. In the beginning, the thermistor acts as a high resistor and helps limit the rush of inrush current. Whenever current passes through a thermistor, it generates power, which makes the thermistor heat up and lose resistance. Once its temperature reaches its stable point, the thermistor reduces the amount of resistance in the current. It can be used in a variety of applications, as it is a simple and reliable technique. When shutting down rapidly, performance issues can occur during the first cycles because NTC thermistors continue to be warmer than expected.

How Active Inrush Current Limiters Work

They work by using a special circuit to identify that the system is powering up and control the current that starts to flow. Generally, a resistor is added early in the circuit to limit the amount of current. When equilibrium is reached, the circuit allows all the current to flow smoothly using the bypass. It is perfect for use in cases where the output must be turned on and off many times or where the motor requires a lot of effort to start up. Since they do not require temperature reliance, active ICLs are more reliable and work well in tough conditions than NTC thermistors.

Types of Inrush Current Limiters

Several technologies are used to limit inrush current, each suited to different applications:

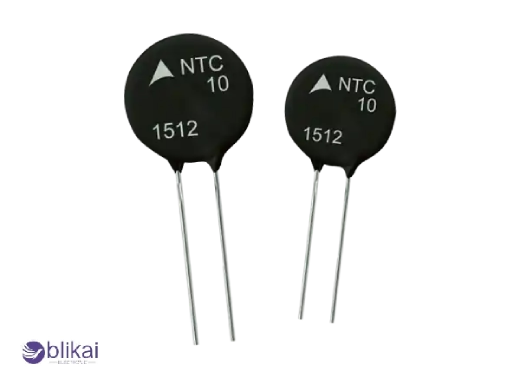

1. NTC Thermistors (Negative Temperature Coefficient)

- Function: These resistors have a high resistance when cold, limiting initial current. As they heat, their resistance drops, allowing normal operation.

- Pros: Simple, cost-effective, self-resetting.

- Cons: Passive devices; can’t handle rapid cycling.

- Applications: Power supplies, LED drivers, battery chargers.

2. PTC Thermistors (Positive Temperature Coefficient)

- Function: Low resistance at room temperature, but resistance increases with current or temperature rise to limit current.

- Pros: Self-regulating, reusable.

- Cons: Slower response, not ideal for high inrush loads.

- Applications: Transformer protection, motor windings, heating elements.

3. Fixed Resistors with Relay Bypass

- Function: A fixed resistor initially limits current, then a relay bypasses it once the inrush phase is over.

- Pros: Handles large inrush currents, fast recovery.

- Cons: More complex, requires control circuitry.

- Applications: High-wattage power supplies, industrial equipment.

4. Active Inrush Current Limiters (IC-based)

- Function: Use electronic control (e.g., MOSFETs or ICs) to limit current during startup dynamically.

- Pros: Precise control, compact, efficient.

- Cons: More expensive, design complexity.

- Applications: Server PSUs, telecom equipment, high-end consumer electronics.

Key Factors When Choosing an Inrush Current Limiter

When selecting an inrush current limiter, consider the following:

- Load type (capacitive, inductive, resistive)

- Startup current magnitude

- Voltage and current ratings

- Ambient temperature

- Duty cycle and startup frequency

Common Applications of Inrush Current Limiters

Power Supply Units (PSUs)

A majority of PSUs are equipped with inrush current limiters that regulate the amount of current that occurs when they start up. After the PSU is turned on, some big filter capacitors draw a big current which might lead to damage or tripping of the system in the beginning. Thanks to an inrush current limiter such as a thermistor, the initial huge current is prevented. It rises gradually because the limiter increases its resistance suddenly. Due to this protection, the power supply works for a longer time, the system is safer and everything is more stable. Since these systems run on machines and consumer products, they must boot up without delay.

LED Lighting Systems

When LED drivers and capacitors turn on instantly, inrush current limiters in most modern LED lighting systems help manage these large current spikes. If not controlled, the early overcurrents can wear out the LED components and place too much strain on the system’s main components. They help extend the life of LED systems and keep annoying shutdowns of circuit protection devices at bay in commercial, outdoor and industrial lighting systems. When limiters are applied to LEDs, manufacturers achieve efficient energy use, durability and meet the rules set by government authorities for current and power standards.

Electric Motors and Drives

Electric motors in HVAC, compressors and industrial machinery typically draw several times the rated current when starting up. As a result, electricity sources can be pushed too far, windings may suffer, and overall, the system’s performance improves less. An air bending advisor, such as an NTC thermistor or active circuit, is sometimes used to manage the surge, allowing current to rise gradually and lessening the danger to both the machine and its electrical system. As a result, motor lifespan is increased, starting the motors is easier and nearby devices will not be affected by erratic voltage drops. This application plays a key role in manufacturing, elevators and electric cars.

Audio and Amplifier Equipment

High-fidelity systems and amps need to have a constant power supply to work properly. However, after turning on, these devices draw a high peak of current because they are charging large internal capacitors and magnets in their transformers. If left unchecked, the sudden surge can ruin the inner components or lead to popping and hissing sounds in your speakers. They are in place to reduce these problems and to create a quieter and safer start for the power supply. They also save power switches and fuses from becoming overloaded, allowing premium studio, theater and high-end audio system components to remain unharmed over time.

Battery Chargers and UPS Systems

When connecting large batteries, power from battery chargers and UPS systems must be sufficient to recharge capacitors, which use large amounts of current. A current limiter prevents excessive current from reaching the control electronics, which could damage them, make the fuses blow or shorten the system’s useful life. They are most important when used in large systems such as data center applications, backups and telecommunication systems. They also help reduce waste and ensure that backup power sources are dependable whenever the main power fails.

Industrial Equipment and Machinery

Industrial welders, CNC tools and robotic arms use a lot of power and can bring in a huge amount of current when turned on. When there is a sudden surge, the equipment may shut down and function less effectively, causing downtime. They are placed in control panels and at the beginning of the power path to control how the circuitry behaves when it is turned on. With this protection, the equipment continues to meet the safety and performance rules required by industry. Having inrush protection is necessary to ensure stable operations and avoid spending a lot to stop and restart production.

Consumer Electronics

Inrush current limiters are used regularly in televisions, gaming consoles, printers and microwave ovens too. Most of these devices rely on switching power supplies that require large starting currents. Suppose uncontrolled surges can damage important parts inside a TV and cause the house breakers to turn off, interfering with the TV’s use. With inrush current limiters, manufacturers make products more robust, less prone to failing from power complications and simpler for regular households to use. Ensuring electronics are repaired and remain active for longer is an essential trait that people rarely think about.

Conclusion

An inrush current limiter is essential for the safe and effective startup of various electrical equipment. Making the correct choice between an NTC thermistor, a relay-based inrush limiter or an active IC for any system—simple or complex—can defend the system, enhance dependability and prevent serious failures.

FAQs

Q: Can NTC thermistors be reused after tripping?

A: Yes, but only after they have cooled down. Frequent cycling can reduce their effectiveness.

Q: Are active inrush limiters better than passive ones?

A: They offer more precise control and faster response, making them ideal for high-end applications, though at a higher cost.

Q: What happens if I don’t use an inrush current limiter?

A: Your circuit may experience blown fuses, degraded components, or startup failures due to excessive current surges.

Related Articles

ACS712 Current Sensor:Principle,Features and Applications

Flexible Alternating Current Transmission System:Working and Types

MLX91221KDF-ABF-120-RE Melexis Current Sensor

2N3904 vs 2N2222:What You Need to know

Cross Sectional Area of Wire: Everything You Need to Know

Understanding Coupled Inductors: Operations and Practical Applications

What is Amorphous Silicon Solar Cell?

Difference Btween Amplifier and Current-Sense Amplifier

Why Using Op Amps as Comparators?

10k Resistor Color Code: Everything You Need to Know

CR2450 vs CR2032 Battery: What are the Differences?

SN6505BDBVR Transformer Driver: Features, Application and Datasheet

0603USB-251MLC TRI Component: Features, Applications, and Datasheet