FPGA vs ASIC: Which one should you Choose?

FPGA vs ASIC

Electronic product designing uses both FPGAs and ASICs as types of integrated circuits. In FPGAs and ASICS, logic cells are arrayed and programmed using hardware description languages which are similar to their circuit design flow. Their purpose and function, however, differ greatly between the two technologies. We'll compare the advantages and disadvantages of using FPGAs and ASICs in this article. Moreover, after reading our detailed article which is about FPGA vs ASIC, you are quite confident in picking the best one for you according to your requirements. So without wasting more time, let's get started!

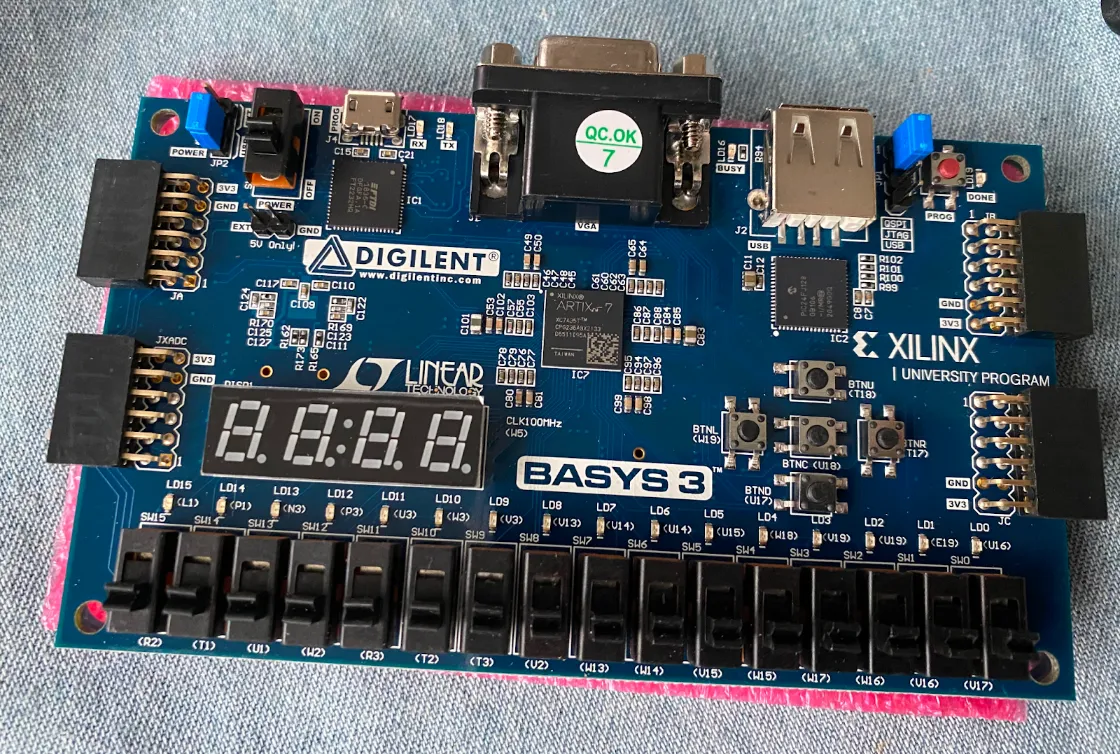

Introduction to FPGA

Field Programmable Gate Arrays are called FPGAs. A field-programmable integrated circuit can be used exactly as intended after it has been purchased. Microprocessors, encryption units, graphics cards, or even all three can operate simultaneously. The FPGA is field programmable, as implied by its name. As a result, an FPGA can be reprogrammed in the field to act as a graphics card instead of being produced in semiconductor factories. VHDL and Verilog are two of the most commonly used hardware description languages when designing FPGAs.

Several thousand Configurable Logic Blocks (CLBs) are embedded in programmable interconnects on a FPGA. Look-Up Tables (LUTs), Multiplexers, and Flip-Flops are the main components of CLBs. Complex logic functions can be implemented with them. Apart from CLBs and routing interconnects, FPGAs also contain hard-silicon blocks. An FPGA may include a block RAM, a DSP block, an external memory controller, a PLL, and a multigigabit transceiver, for instance. There has been a recent trend toward embedding an ARM Cortex A9 based processor core inside the FPGA die itself (for instance for Xilinx Zynq). FPGAs are designed to handle high-speed acceleration, which processors cannot handle, whereas processors handle mundane tasks. Competing with ASICs requires dedicated hardware blocks.

What is ASIC?

What is ASIC

Application Specific Integrated Circuits are called ASICs. ASICs are application-specific, as their name implies. Throughout their entire operating life, they serve a single purpose. CPUs in phones, for instance, are ASICs. The CPU is meant to be used for the entire life of the device. Silicon flip-flops and gates are permanently connected in silicon, so it can't be changed to perform any other logic function. With hardware description languages such as Verilog or VHDL, ASIC logic functions are specified similarly to FPGA logic functions.

FPGAs, on the other hand, make circuits by connecting a number of configurable blocks in a manner similar to ASICs but permanently drawn in silicon. Using Lego block construction versus concrete construction, you can compare the two. FPGAs are analogous to the former, and ASICs to the latter. The Lego blocks can be reused for other designs, but the concrete castle will last a lifetime.

FPGA vs ASIC: How Do They Differ?

My comparison of FPGAs and ASICs is divided into three sections: technology, commercial viability, and application. It usually comes down to which suits your individual needs in terms of which technology is better in terms of various applications and criteria.

NRE: Non-Recurring Engineering Costs are also referred to as NREs. A business's concern increases when the words recurring and costs are combined. Hence, this is one of the most important deciding factors. Additionally, this is exceptionally high when it comes to ASIC, while it is nearly nonexistent with FPGAs.

It should be noted, however, that the total cost decreases as the quantity of ASICs you need increases. Due to its higher individual costs per unit than ASIC, FPGA can be more expensive in the long run.

Performance and Efficiency: Compared to FPGAs, ASICs have lower power consumption and are able to integrate a wide range of functionalities onto a single chip, making them perform better. An ASIC, on the other hand, can be designed for power efficiency or speed, while an FPGA is more rigid.

Power Consumption: The ASIC requires less power and thus provides a better alternative to the FPGA, which consumes more power. Particularly when it comes to battery-operated electronic devices.

Cost: As compared to FPGAs, which are only profitable when produced in small quantities, ASICs are still considered more cost-effective, even with the increased NRE costs.

Design Flow: A simpler and more trouble-free design process is preferred by all engineers and PCB designers. The process itself does not have to be complicated just because the work you do is complex. FPGAs are therefore less complicated than ASICs in terms of design flow simplicity.

A major reason for the widespread use of FPGAs is their versatility, flexibility, and short time to market. Due to ASIC's non-reprogrammability and the need for costly EDA tools, the design flow is more involved with ASIC.

Time to Market: Additionally, FPGA designs are simpler than ASICs, which allows them to be brought to market faster. It takes a great deal of time and resources to design an ASIC, process it, and verify it, among other things.

Size: The size of an object is determined by physics. Due to the fact that an ASIC has been designed to perform a single function, it is precisely equipped with the gates it requires to perform that function. Due to its internal structure and specific size, FPGAs' multifunctionality results in a unit that is significantly larger than a single unit.

Configuration: In general, FPGAs are more programmable than ASICs. Thus, it stands to reason that FPGAs offer a greater level of flexibility. As well as being flexible, FPGAs can also be "hot-swapped" to allow modifications while in use.

Analog Designs: The use of FPGAs is not possible if your designs are analog. In addition to using analog hardware for designing analog in ASICs, analog-to-digital converters and RF blocks can also be created by analog hardware.

Barriers to Entry: A barrier to entry is a situation that makes it difficult to acquire these technologies and incurs high upfront costs. ASICs have exceptionally high NREs due to their complexity of operation and design. The cost of developing ASICs can reach millions of dollars, while that of developing FPGAs can start at a few thousand dollars.

Per Unit Cost:

As a result, ASICs are ideal for mass production design projects despite having a higher NRE than FPGAs.

Operating Frequency: FPGAs have limited operating frequencies based on their design specifications. In addition to its flexibility (reprogrammable), this is another side effect. ASICs, however, can operate at higher frequencies due to their more focused approach to functionality.

FPGA vs ASIC: What are the Advantages?

Advantages of ASICs

It is important to explore ASICs' unique advantages once we have understood what they are and what they are commonly used for. Custom development is justified by the need for these benefits in a number of applications. To help you better understand these advantages, let's look at them in more detail:

High Performance: ASICs offer high performance as one of their main advantages. A custom-designed system can be speeded up and optimized to be as efficient as possible, since it is specifically designed for a specific application. Due to their tailored architecture and dedicated hardware resources, ASICs often perform better than general-purpose processors in their target applications.

Low Power Consumption: Low power consumption is a critical requirement for applications using ASICs, which are designed to be power efficient. The design of an ASIC reduces active components and power consumption compared to a general-purpose processor when it is specific to a specific function. Smartphones and IoT sensors, for example, use batteries, making energy efficiency a critical factor.

Small Form Factor: In comparison to general-purpose processors, ASICs have a smaller form factor. In applications like wearables and embedded systems, space is limited. In addition to improving thermal performance, the smaller size also increases cooling efficiency.

Intellectual Property Protection: Compared to off-the-shelf components, custom ASICs can provide greater intellectual property protection. In addition to protecting IP from reverse engineering and unauthorized use, companies can also protect proprietary algorithms and functionality directly in hardware.

Mass production at low cost: With increasing production volume, the per-unit cost of ASIC design and fabrication decreases significantly. For high-volume products, ASICs are cost-effective due to their speed, low power consumption, and small form factor.

Multi-functional Integration: Using ASICs reduces the need for additional components and simplifies the overall design of the system as multiple functions and components can be combined on one chip. Consequently, system complexity can be reduced, manufacturing costs can be reduced, and reliability can be improved.

Advantages of FPGAs

Flexibility and adaptability are two key advantages of FPGAs. Here are some more details about these benefits:

Design Flexibility: FPGAs have the advantage of being flexible in terms of their design. The functionality of an FPGA can be modified after it has been manufactured by reprogramming it with new digital circuits and functions. The design flexibility of FPGAs makes it easier to integrate them with many peripherals. As a result, FPGAs are attractive for development and prototyping of rapid prototypes, proof-of-concepts, and other applications requiring design modifications.

Shorter Time-to-Market: Because FPGA design does not require lengthy fabrication and manufacturing steps, it is generally faster than ASIC design. The ability to respond to changing market demands and emergent trends quickly makes it ideal for fast-paced industries.

NRE costs are reduced:

It is less expensive to manufacture and design FPGAs than ASICs, which require significant upfront investment. A FPGA is a more cost-effective solution for projects with low volumes or limited budgets because of their low cost.

Field Upgradability: Field-programmable FPGAs allow for updates and modifications without physically changing the hardware. By enabling the system to be upgraded in the field, maintenance costs can be reduced and the system can last longer.

Parallel Processing Capabilities: A FPGA is a device that operates independently and concurrently, consisting of multiple programmable logic blocks. Among other applications, FPGAs excel at digital signal processing, image processing, and cryptography because of their parallel processing capabilities.

Technology Adaptability:

In applications requiring ongoing updates and enhancements, FPGAs are a future-proof solution that can be reprogrammed to support new technologies and standards. Companies can take advantage of this adaptability to remain competitive and extend their product life cycles. Due to their ability to reconfigure, FPGAs are ideal for projects requiring various interfaces.

Lower Risk of Obsolescence: As a result of their reprogrammability, FPGAs are less likely to become obsolete than ASICs. With the ability to adapt to new technology, the FPGA can stay useful for a longer time.

When Would You Use an FPGA?

Although ASICs can be advantageous, FPGAs are sometimes preferable to engineers. If you don't plan on doing a large production run, these microchips are a more convenient option.

When choosing an FPGA, you should consider:

-

Future reprogramming of the chip is needed: You may need to use an FPGA if you need the ability to reprogram a chip over other features such as efficiency.

-

Prototypes should be created before mass production: Once your design is complete and you know which functions you will include, you can use FPGAs for prototypes even if you plan to create ASICs.

-

Looking for a ready-to-go option: Designing an ASIC is a more complex and time-consuming process. FPGA chips allow people to get to market faster when compared to ready-made ones. You can ensure that your product will perform exactly as intended by investing time and money into developing an ASIC.

What Makes An ASIC a Good Choice?

ASICs are an obvious alternative to field-programmable gate arrays (FPGAs), but they have their own pros and cons. According to your design objectives, an ASIC may be more advantageous in many scenarios than an FPGA. Choosing an ASIC design has the potential to bring you a number of benefits, including efficiency, cost-effectiveness, and production volume.

FPGA vs ASIC: Comparison Summary

The pros and cons of FPGAs and ASICs are apparent when comparing their hardware design approaches. It depends on the scope, business requirements, and capabilities of your project to choose the right approach. The complex, volume, budget, prototyping requirements, and launch deadlines of a product must all be considered in the evaluation of a product.

As our embedded engineers are ready to assist you on any question, you don't need to choose the hardware design approach on your own. The product design, development, testing, and launch will be carried out according to the core requirements of the project. Furthermore, if you still have any confusion while buying or question about FPGA vs ASIC, then you can comment below. Thank You!