How Does Metal Oxide Varistor Work?

It happens often that electrical spikes destroy electronic equipment-a situation familiar to many homeowners and business owners. What if there were a tiny component available that could protect these expensive devices against such potential disaster?

Understanding Metal Oxide Varistors (MOVs)

Metal Oxide Varistors (MOVs) are an economical solution to clamping off transients or spikes. These voltage-selective resistors are made of ceramic semiconductors exhibiting nonlinear current-voltage characteristics that enable fast adaptation of resistance to fluctuating voltages. MOVs effectively clamp excessive voltage by offering surge currents an easier path through lower resistance paths; protecting sensitive components from damage by providing low resistance routes for surge currents.

Components and Structure

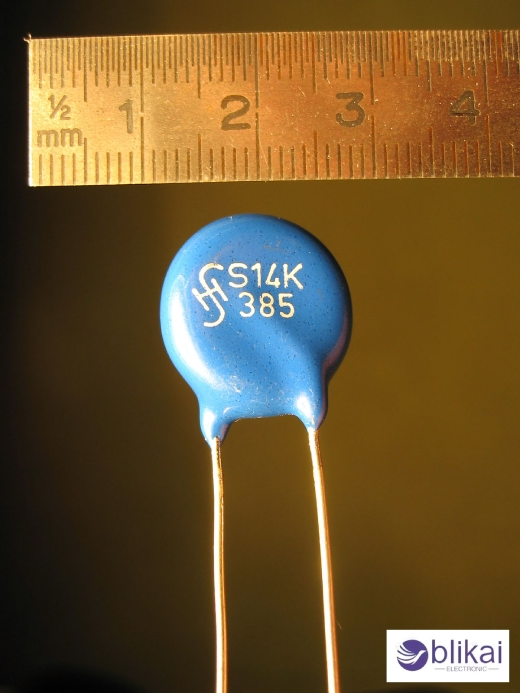

An MOV consists of a ceramic matrix of zinc oxide grains with small amounts of other oxides of metals such as bismuth, cobalt, or manganese. The role of these additives is to create interference between the zinc oxide grains, thus forming myriads of microscopic, p-n junctions within the MOV. The device is typically disc-shaped, with metal electrodes on both faces for electrical connection. This unique structure allows MOVs to handle high energy dissipation in a compact form factor.

Electrical Symbol and Representation

In circuit diagrams, MOVs are represented by a symbol resembling a resistor with two diagonal arrows pointing towards it. This symbol reflects the device's voltage-dependent nature and bidirectional operation. The two diagonal arrows indicate how it responds to changes in both positive and negative voltage transients, making MOVs ideal for protecting both AC and DC circuits from transient voltage transients.

Types of Metal Oxide Varistors

Disc varistors

Disc varistors (MOVs) are one of the most frequently encountered Metal Oxide Varistors (MOVs). These circular components are formed by compressing metal oxide powder, typically zinc oxide, into disc shapes before sintering at high temperatures to form MOVs. Due to their high energy absorption capability and wide range of applications such as power distribution or industrial equipment protection systems, disc varistors are particularly suitable for protecting electrical systems against voltage surges and transients.

Multilayer chip varistors

Multilayer chip varistors are compact, surface-mount devices designed for use in smaller electronic circuits. Their compact form combines multiple layers of metal oxide material bonded by electrodes into one chip for maximum voltage ratings in smaller packages - perfect for portable devices, computers and telecommunications equipment.

Surface mount varistors

Surface mount varistors (SMVs) have been specifically designed to aid in the process of automated assembly manufacturing today, so far as manufacturing is concerned. Due to their ability to take chip-type or array-type forms, surface mount varistors comprise a reliable protection from electrostatic discharge (ESD) alongside other transient voltage events across a range of electronic devices, including smartphones or automobile electronics.

Applications of Metal Oxide Varistors (MOVs) in Electronics

A. Surge protection devices

Among other applications, Metal Oxide Varistors act as a standard surge protection device, wherein MOVs form the first line of defense against any sudden increases in voltage. MOVs are used in power strips, surge protectors, and uninterruptible power supplies (UPSs). When a sudden voltage surge occurs, MOVs act very quickly by dropping resistance low enough to divert excess current from sensitive electronic devices and to thereby protect them.

B. Voltage regulation

MOVs play an essential role in voltage regulation circuits, helping to ensure consistent voltage levels across electronic systems. By clamping voltage at specific thresholds, MOVs ensure equipment receives reliable power supply - protecting it from over-voltage conditions while improving system reliability.

C. Lightning arresters

MOVs play an essential role in outdoor electrical systems as lightning arresters. These devices protect power distribution networks, transformers and other high-voltage equipment from lightning strikes by rapidly diverting energy surges back down to earth to save precious infrastructure from destruction.

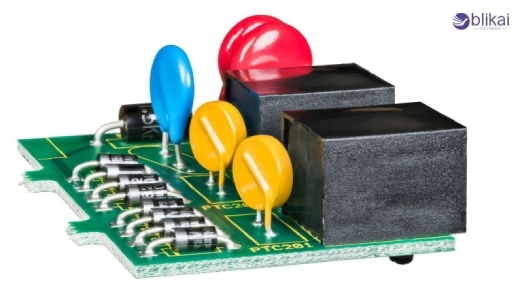

D. Telecommunication equipment

Telecommunication equipment relies heavily on MOVs to safeguard sensitive electronics from voltage transients. MOVs are integrated into routers, switches and other network devices' circuit boards to help prevent power fluctuations from damaging devices while guaranteeing uninterrupted communication services.

E. Industrial machinery protection

MOVs play an essential role in protecting expensive machinery and control systems against electrical disturbances. MOVs are incorporated into motor drives, PLCs and other automation equipment to increase reliability and extend the lifespan of critical industrial assets.

Advantages of Using Metal Oxide Varistors (MOVs)

Fast response time

With such a fast response time of a few nanoseconds or faster to voltage transients, Metal Oxide Varistors (MOV) are perfect for the protection of sensitive electronic circuits within an application.

High energy absorption capability

One of the key advantages of MOVs is their ability to absorb substantial amounts of energy during transient voltage events. This characteristic allows them to effectively protect circuits from potentially damaging surges.

Long service life

MOVs are known for their reliability and long service lives, providing reliable protection over many years without needing frequent replacements. When used according to their recommended specifications, these components can offer reliable protection.

Cost-effectiveness

The use of MOVs offers a cost-effective solution for surge protection in various applications. Their benefits include:

- Lower initial cost compared to other surge protection devices

- Reduced maintenance expenses due to long service life

- Minimized downtime and equipment replacement costs

Disadvantages and Considerations

Aging effects

Metal oxide varistors (MOVs) can become worn over time, which can compromise their performance. With repeated voltage surges causing clamping voltage increases and their effectiveness as circuit protectors being reduced over time. This aging process is accelerated by factors such as high operating temperatures and frequent exposure to transient voltages.

Temperature sensitivity

MOVs exhibit temperature-dependent characteristics, which can impact their reliability. As the ambient temperature rises, the resistor's voltage-current curve shifts, potentially altering its clamping voltage and energy absorption capabilities. This sensitivity necessitates careful consideration of operating temperature ranges when designing MOV-based protection systems.

Failure modes

MOVs can fail in various ways, including short-circuit and open-circuit failure modes. Short-circuit failures occur when resistor resistance decreases significantly and could damage components connected to it, while open-circuit failures compromise protection by leaving circuit vulnerable to voltage surges. Understanding these failure modes is crucial for implementing appropriate backup protection measures.

Proper sizing and selection

MOV solution requires carefully considering factors like maximum continuous operating voltage, energy absorption capacity, response time and response time. Undersized MOVs may fail prematurely while oversize ones could incur unnecessary costs and space requirements. Engineers must analyze circuit requirements and potential surge scenarios to ensure optimal MOV selection and implementation.

Conclusion

Metal Oxide Varistors (MOVs) are essential components in modern electronics, providing reliable protection from voltage surges and transients. Utilizing their unique electrical properties, MOVs operate to clamp excess voltages while protecting sensitive equipment - from consumer electronics to industrial applications, MOVs play an essential role in maintaining long-term reliability of electrical systems.

As technology evolves, surge protection becomes ever more crucial. Engineers can bolster electronic device resilience against power fluctuations and lightning strikes by including MOVs in circuit designs - although their drawbacks include fast response times, energy absorption capabilities, cost effectiveness, and other limitations - MOVs are indispensable tools in creating safer and more reliable electrical systems.

Related Articles

Metal Oxide Varistor:Overview,Principle and Applications