Different Types of Mixers

Typical blending phases encompass solid-solid dispersion, solid-liquid amalgamation, liquid-gas integration, and the dual variations of liquid-liquid interaction, where one involves mixable liquids, and the other entails immiscible ones. The extent of amalgamation hinges on the intensity of eddy currents or turbulence and the counteracting forces. When these opposing forces escalate, elevating the level of amalgamation becomes imperative.

What is the mixer?

A mixer constitutes a sophisticated and precise apparatus that amalgamates, emulsifies, homogenizes, and unifies diverse types of constituents crucial to manufacturing or production hgvhjnghngvbn vcb cv v v vbcvincluding pharmaceuticals, cosmetics, and food items, each demanding meticulous control for the blending of dissimilar chemicals and materials.

The excellence of a mixer is gauged by its consistency and the uniformity of its blending. The intricacy of the process lies in the characteristics of the materials undergoing blending, as each nuance and distinction necessitates specialized handling. The initial stages of mixing entail an exhaustive study of the materials to ensure a successful blending process. Like many industrial operations, mixing mandates the tailoring of equipment to precisely align with the requirements and conditions of the manufacturing procedure.

When delving into discussions about mixers, it becomes crucial to differentiate between blending and mixing, which may initially appear synonymous. Blending is a gentler process aimed at achieving a uniform, cohesive distribution of each material, resulting in an entirely novel and unique substance. In contrast, mixing brings together the ingredients, which can potentially revert to their original forms. This aspect of mixers requires careful consideration during the selection process. In the majority of instances, the objective is to produce a new homogeneous substance, indicative of the blending outcome.

The types of industrial mixers encompass compact models that can blend plastic polymers for plastic production, as well as mixers designed for pulverizing and combining pellets and stones. The blending procedure is characterized by its effectiveness, high quality, robust equipment, and reliability. It holds a central role in various industrial applications and processes.

When Choosing an Industrial Mixer

Features of Material to be Mixed

The initiation of the mixer selection process involves a meticulous examination of the substances slated for mixing, a variable contingent on the industry. Common materials encompass liquids, emulsions, slurries, pastes, solid-liquid combinations, and powders or granular substances. The uniformity, properties, and traits of these materials serve as criteria to narrow down the selection of a mixer tailored to the specific application.

Material properties fluctuate based on factors like shape, density, size, and static, dictating their interaction during the blending process. Each of these elements exerts influence on the blending procedure.

Shape - Materials exhibit diverse shapes, such as triangles, oblong shapes, or flakes, each imparting resistance to the blending process. A mixer must alter the physical shape of particles to achieve an optimal blend.

Density - Particle density impacts their flow, with particles of similar density flowing at the same rate and blending seamlessly.

Size - Varied particle sizes lead to smaller particles lodging in spaces between larger ones. Prior to blending, preparation of larger particles is necessary to attain the desired blend.

Static - Particle friction during blending induces erratic behavior and static, managed by static arrestors that dissipate the electrical charge.

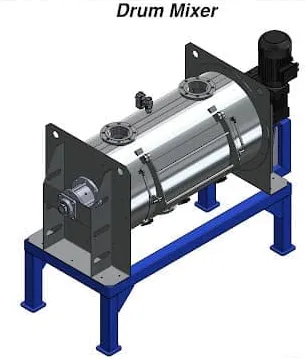

Manufacturers often customize equipment with special features, capabilities, and enhancements to meet specific requirements. The diverse nature of materials necessitates a mixer aligned with their distinct characteristics. Material volume is a critical consideration, with batch volumes tailored to the mixer's capacity for effective blending. Drum mixers may range from 50 to 100 gallons (190 to 380 liters), while agitator mixers can accommodate volumes between 16 to 264 gallons (60 to 1000 liters).

| Type of Industrial Mixer | Engineered for Blending |

| Paddle Mixer | Viscous semi-solid material |

| Horizontal Ribbon Mixer | Food, chemicals, powders |

| Tumbler Mixer | Bakery materials |

| Drum Mixer | Low and medium viscosity material, such as slurry or cement |

| Emulsifier | Immiscible liquids, such as oils |

| Static Mixer | Gasses and liquids |

Liquid Viscosity

The ability of a liquid to resist the mixing process is determined by its viscosity, a measure of how molecules move in relation to each other. Viscosity gauges the resistance to mixing, reflecting the hindrance in the movement of layers within the liquid. Data sheets provide diverse viscosity values measured in centipoise (cps), with one cps representing the viscosity of water in laminar flow. Depending on the material, cps values can reach significant highs.

As viscosity increases, material flow tends to become more laminar, necessitating that the mixer design can meet the required agitation level for homogeneous mixing. In high viscosity mixing, torque and the specific design of mixing blades or impellers become crucial components of the process.

Mixing is quantified by torque, calculated as horsepower divided by RPMs. Horsepower alone is insufficient, prompting high viscosity applications to demand either increased torque or lower RPMs. Elevated torque leads to a demand for enhanced drive mechanisms, larger mixer shafts, and impeller diameters. Specialized impeller designs are tailored to effectively engage and move or entrain viscous fluids.

Higher viscosity fluids exhibit pseudoplastic or thixotropic behavior, deviating from the laminar pattern. Laminar fluids, characterized by high momentum diffusion and low momentum convection, are less common. Pseudoplastic and thixotropic fluids, shear-thinning in nature, differ in time dependence, resembling the challenge of extracting ketchup from the bottom of a bottle. Shaking induces shear, thinning the fluid and facilitating flow.

Mixers equipped with gearboxes capable of reducing RPMs and increasing torque yield optimal results for high viscosity mixing. The heightened torque necessitates a mixer shaft with adequate diameter to drive impellers featuring broad blades and an aggressive pitch to maximize surface contact.

Vessel Capacity

Smaller tanks exhibit enhanced pumping capabilities, while larger tanks operate conversely. This dynamic explains why large 100,000 barrel oil tanks employ side-entering mixers, requiring extended time for blending. It also elucidates the prevalence of numerous small support mixers dedicated to a few large tanks. The smaller vessels are instrumental in production, while the larger tanks serve as storage units.

Mixing Time

The blending process encompasses various stages, from loading and packing to cleaning. Consequently, understanding the actual time required by the mixer to blend products is crucial. Each mixer has a characteristic average true mixing time, factoring in estimates for loading and packing, contributing to an extended cycle duration.

Ease of Cleaning

Certain mixer types comprise numerous moving parts, leading to product dislodgment that adheres to bearings, mixer walls, and paddles. This product wastage is considerable and raises concerns of cross-contamination due to potential carrier effects.

Hence, it is essential to factor in the overall drying and cleaning time for the mixer components. Nevertheless, the process of removing and reattaching the parts is time-consuming. It necessitates care and patience during the reassembly of components. The primary objective in choosing the right mixer is to ensure a highly efficient manufacturing process, underscoring the importance of meticulousness.

Impeller Speed

Impeller speed refers to the distance an impeller covers within a specific time frame. It is determined by multiplying the impeller diameter by pi, representing the outermost circumference of the impeller. When this circumference is multiplied by the impeller's revolutions per minute (rpm) or revolutions per second (rps), the result is the tip speed, measured in feet per minute or meters per second.

In dry material mixers, tip speed serves as a crucial parameter influencing cycle times, with faster tip speeds corresponding to shorter cycles. Slow-speed mixers, such as ribbon blenders, typically exhibit a tip speed of 1.4 meters per second. Medium-speed mixers, like horizontal mixers, operate within the range of 6 to 10 meters per second. High-speed mixers, exemplified by vertical high-speed mixers, achieve tip speeds ranging from 28 to 40 meters per second.

Once the tip speed surpasses a certain threshold, fluidization occurs, causing dry material to behave akin to a liquid. This reduction in cycle times facilitates a homogeneous mix, analogous to the difference between manually stirring ingredients in a bowl versus using a food processor or blender. Vertical and horizontal high-speed mixers achieve fluidized mixing, while ribbon blenders do not.

Higher mixing speeds demand increased power. Ribbon blenders typically require 1 horsepower per 100 lbs. (45.3 kg) to 200 lbs. (90.7 kg) of material, whereas vertical high-speed mixers can handle less than 4 pounds (0.45 kg) per 1 horsepower.

Tip speed significantly influences the dispersion of agglomerated particles, a crucial aspect of dry material mixing involving larger particles combined with very small agglomerated ones. To attain a homogeneous blend, it becomes essential to separate small particles that are stuck together, as seen in the mixing of plastic powder with pigments. Pigments, characterized by micron (µ) size particles, are often agglomerated and require a specific energy input for separation.

Vertical mixers possess the energy needed to fluidize the mixture and disperse small agglomerated particles. Medium-speed horizontal mixers can achieve separation, though not to the extent seen in vertical high-speed mixers. If a medium-speed mixer incorporates high-speed choppers, the tip speed of these chopper blades matches that of the main mixing blades in a high-speed mixer, aiding in the dispersion of agglomerated ingredients.

Varieties of Mixers

The choice of a mixer hinges on its intended application and the nature of substances involved, spanning chemicals, liquids, gases, granules, and pellets. The realm of industrial mixers offers a diverse array tailored to handle materials that might initially seem challenging to blend. Categorized broadly, mixers fall into three types: diffusing, shearing, and convection. Each category boasts distinct constructions, impeller types, speeds, and functions. A fundamental grasp of each type proves beneficial when selecting an appropriate mixer for a given application.

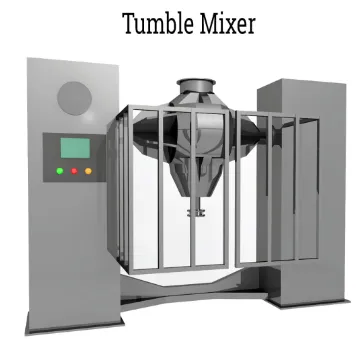

Tumbler Mixers

Tumbler mixers, classified as diffusion mixers, employ rotation to blend materials while introducing air into the mixing process. Operating with a tumbling rhythm, these mixers eschew impellers in their mixing process. Tumbler mixers find utility in blending solids and powders and, under specific circumstances, liquids.

Solids within a tumbler mixer are stirred by the rotational motion, akin to being stirred by gravity as the mixture consistently descends back to the drum's bottom. Tumbler mixer configurations encompass octagonal, cone, and V shapes.

High Shear Mixers

High shear mixers, alternatively known as high shear reactors (HSRS) or rotor-stator mixers, cater to the amalgamation of solid and liquid materials for emulsification, homogenization, dispersion, particle size reduction, and disintegration. These high-speed machines feature powered mixing blades, referred to as shears. The materials processed by high shear mixers differ from easily miscible substances that low shear mixers can blend effortlessly.

High shear mixers find application with ingredients that resist easy blending, exhibit immiscibility, and demand more rigorous and forceful treatment, such as liquids with varying viscosities or containing solids requiring breakdown. A prevalent form of high shear mixing is dispersion, employing high speed and substantial shear processing with increased horsepower. As dispersion blades rotate, they engage particles, breaking them apart. A horizontal laminar flow disperses or dissolves the material flow generated by the blades either upward or downward. High shear mixers excel in mixing liquids and solids that conventionally resist amalgamation, such as oil and water. Initially prevalent in the rubber industry, they have expanded their usage to various sectors, including chemical, food, pharmaceutical, cosmetics, and adhesive industries.

High-Speed Mixers

High-speed mixers come into play where substances need rapid cooling, granulation, or dispersion to expedite their preparation for subsequent processing steps. These mixers are deployed across industries like food processing, pharmaceuticals, and paint production. Available in a spectrum of sizes and shapes, ranging from small, high-speed lab mixers to industrial-sized counterparts, high-speed mixers efficiently handle diverse processing requirements.

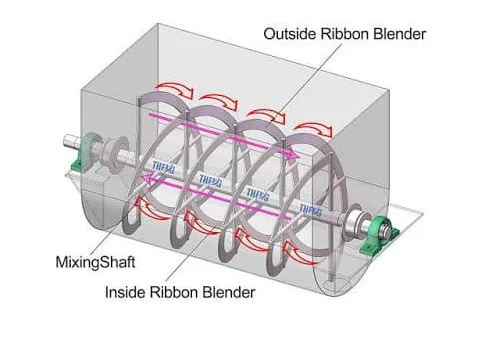

Ribbon Blender

A ribbon blender derives its name from the blade configuration, consisting of inner and outer helical ribbons forming the paddles. These ribbons move material inward and outward during blending. Outer blades draw product from the mixer's sides to the middle, while inner ribbons move the product out to the sides, generating a convective mixing pattern.

Primarily used for blending powders, ribbon blenders excel in solid-on-solid mixing. The design allows for fast and efficient mixing cycles, ranging from a few minutes to under twenty minutes, with a tip speed of approximately 1.4 meters per second. Despite the rapid process, ribbon agitators operate at a slow speed, ensuring a gentle folding action.

While effective in achieving homogeneity, ribbon blenders come with a higher cost compared to paddle mixers and are relatively more challenging to maintain.

Paddle Mixer

Paddle mixers feature agitators shaped like paddles, gently scooping, lifting, and tumbling materials. Ideal for ingredients with varying shapes, sizes, densities, and viscosities, paddle mixers excel in blending fragile components such as nuts or fiberglass strands.

The pitched paddles of a paddle mixer induce a three-dimensional figure-eight motion, pulling material from each end to the middle and down the sides. The dual shafts' rotating motion creates a kneading and folding action, continuously feeding material and binder into the mixer.

Agitator Mixers

Designed for liquid or flowable applications, agitator mixers, like those in top-load washing machines, showcase visible agitation. They typically consist of a stationary central agitating blade while water agitates during rotation. Industrially used agitators for food and beverage processing adhere to a similar principle and configuration.

Agitator mixers find application in solid suspension, dissolving gases into a liquid, blending miscible liquids, and transferring heat within a liquid. Classified as axial or radial based on the impeller blade's angle with the liquid and rotation plane, they handle highly viscous materials.

Axial Flow Impellers

In axial flow impellers, the blade creates an angle of less than 90 degrees with the rotation plane, causing the locus of flow along the impeller's axis.

Radial Flow Impellers

Radial flow impellers feature blades parallel to the impeller axis, releasing flow beside the impeller's radius in distinct designs.

Rotor Mixers

Rotor mixers employ metal blades positioned at the container's bottom, spinning at variable speeds. These mixers, often found in blenders, can operate with various detachable attachments for diverse applications in industries like food production, adhesives, pharmaceuticals, and chemical processing.

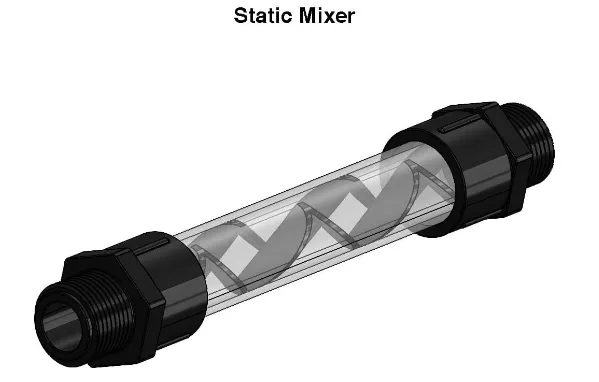

Static Mixers

Static mixers employ a non-moving mixing element, such as a twisted ribbon or helix, placed in a cylinder. Without any moving parts, these mixers disrupt and block the flow of liquids or gases forced through one end of the cylinder.

As liquids or gases pass through the static mixer's cylinder, the mixing element's shape induces turbulence, breaking down molecules and dispersing gases into immiscible liquids to form a homogeneous solution. Static mixers are not suitable for mixing solids, granules, or powders.

Static mixers find prominence in production lines favoring a continuous material flow over batch mixing. Consequently, they contribute to streamlined operations and accelerated mixing by effectively blending constant and consistent liquid streams. These mixers afford a heightened level of control over the desired mixing degree, tailored to the specific outcome – ranging from homogenous blends to less precise mixtures.

Industries such as chemical, cosmetic, automotive, pharmaceutical, and water treatment frequently leverage the benefits of static mixers. These mixers prove particularly effective when employed with low viscosity liquids and materials.

Disperser Type

A disperser employs concentrated and high-speed force to disintegrate, dissolve, and dissipate solids present in powdered materials or liquids. Mixing shafts may feature disc-shaped blades attached, enabling maximum rotational speed. This ensures proper flow, dispersion, and consistency during the blending and mixing process. Dispersers find application in food production, playing a role in liquifying solid ingredients or solidifying materials during storage. They are particularly effective in processes involving incompatible substances that demand additional force for a thorough mix and blend, as seen in adhesives, cosmetics, and pharmaceutical production.

Emulsifier Mixers

Emulsifier mixers are instrumental in mixing immiscible liquids, exemplified by the challenge of blending oil and water. In applications requiring a completely homogenized and emulsified mixture, such as in the production of sunscreen, lipstick, lotion, and cosmetics, emulsifiers come into play. These specialized mixers utilize pressure, isolated vacuum-filled equipment, and high shear for complete liquid-liquid substance mixing. Vacuum emulsifier homogenizers incorporate centrifugal force to drive materials into the work head for breakdown into smaller particles. For instance, in the production of cream and milk, emulsification breaks down large fat molecules in cream to a size similar to milk molecules.

Homogenizer Mixers

Homogenizer mixers are employed in combining liquid-liquid mixtures and solid-liquid mixtures, utilizing extreme force, shear, and pressure to homogenize the mixture effectively.

Heavy Duty Mixers

Designed for mixing viscous and pasty substances, heavy-duty mixers prove crucial when dealing with thick slurries like pasty ingredients, wax compounds, and putty. These mixers, including planetary and multi-shaft mixers, are engineered to handle high viscosity exceeding 750,000 centipoises.

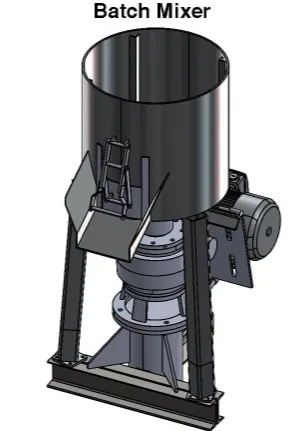

Batch Mixers

Batch mixers, featuring a cylindrical design, enable loading ingredients at one end and dispensing the mixed product at the other. With high capacity, they can prepare batches ranging from thousands of gallons to liters. Batch mixers, including horizontal twin-shaft mixers, ribbon blenders, paddle mixers, and top entering mixers, are suitable for quality-controlled mixing. Batch mixers are commonly used for products requiring quality testing and are ideal for powdery ingredients sensitive to chemical changes over time. These mixers facilitate the addition of ingredients in portions, allowing for multiple mixing processes simultaneously.

Drum Mixers

Drum mixers, equipped with single or multiple blades attached to the inside walls of the drum, rotate the ingredients as the blades lift and raise them to the upper wall. This process repeats during drum rotation. Drum mixers, known for their transportability, tight seal, and small footprint, handle materials with varying particle sizes and low to medium viscosities. Classified as batch mixers, they mix one batch at a time.

Spiral Mixers

Spiral mixers employ a pulley system, motorized to rotate both the bowl and the spiral arm. This gearless mechanism ensures smoother, more uniform, and quieter motion, allowing for gentle blending of ingredients.

The motion of a spiral mixer can be unidirectional or bidirectional, contributing to improved mixing consistency. Bidirectional spiral mixers are particularly advantageous for ease of cleaning and use. Additionally, these mixers boast an absorption rate (AR) ranging from 80% to 90%, reducing the required amount of ingredients per batch. Spiral mixers are available in sizes ranging from 180 lbs. to 440 lbs., featuring a footprint suitable for various mixing operations.

The aforementioned mixers represent just a fraction of the diverse range offered by manufacturers in standard designs. The array of mixers extends from conventional designs to custom-manufactured types tailored to suit unique and specialized applications.

The table below showcases additional innovative and efficient mixer designs that enhance the blending process effectively.

Mixer Extruder

A mixer extruder combines the features of a high shear mixer with a low to medium pressure extruder, facilitating kneading, mixing, and extrusion. It can function as a standalone processor or in conjunction with other mixing methods. Mixer extruders are instrumental in mixing solids and liquids into a viscous, homogeneous paste.

The configuration includes a single horizontal shaft with a screw propelling material through the chamber. Material is fed from a hopper and propelled by the screw to the stationary anvil, continuously undergoing kneading and mixing.

High-pressure mixer extruders excel in mixing materials for high-pressure extrusion, while twin-screw low-pressure mixer extruders are suitable for high powder content or continuous mixing applications. Renowned for significantly reducing process times, often from weeks to 45 minutes, mixer extruders economically enhance material characteristics such as strength. They find applications in waste processing, compounding improvement, and managing high solids or powder content.

Kettle Mixers

Kettle mixers, designed for high-volume production, are high-output mixers that utilize a steam jacket for uniform cooking of liquids. The mixer section is a variable-speed unit adaptable to different materials. Typically equipped with two agitators—one for scraping and one as a secondary mixer—kettle mixers are powered by gas, electricity, or direct steam. Capacities range from 20 gallons to 100 gallons, with twin kettle mixers capable of simultaneously handling two large volumes. These mixers can be mounted on three-pronged legs with flanged feet or a modular base. Tilting kettle mixers feature a handle for pouring, while stationary mixers have valves with a spout for content removal.

Vacuum Mixers

Vacuum mixers eliminate voids in mixtures, enhancing dispersion, degassing, and improving drying at lower temperatures. Operating under lower pressure than atmospheric pressure, vacuum mixers reduce gas molecules per unit volume compared to ambient air. Void-free mixtures contribute to the strength and precision of parts, preventing decomposition of sensitive ingredients and inhibiting potential chemical reactions or microbial growth.

Batch mixers can be configured as vacuum mixers, including single-shaft mixers like high-speed sawtooth dispensers or rotor-stator mixers suitable for low-viscosity materials. Working in an air-deprived environment prevents the formation of bubbles, which can lead to foaming, air pockets, heat exchanger fouling, and cavitation. When selecting a vacuum mixer, factors such as mixing speed, vacuum level, batch volume, particle size, and heating or cooling requirements must be considered.

Applications for Mixers

Mixers find extensive applications across various industries, playing a crucial role in the processing, blending, and treatment of diverse materials. Tailoring their characteristics to specific industries, mixers deliver unparalleled performance and quality.

Adhesives and Sealants

The adhesive and sealant industry relies on mixers for blending miscible fluids and dispersing high-viscosity dissimilar materials. Mixing is a pivotal aspect of adhesive and sealant production, encompassing homogenization of adhesive emulsions, polymer dissolution in solvents, and rubber mastication. Efficient mixing equipment is vital for ensuring productivity and product quality.

Batteries and Electronics

Mixers serve multiple purposes in the battery and electronics sector, including the production of aluminum oxide silicone gels, pastes, slurries, and conductive ink. The choice of a mixing process depends on the unique characteristics, properties, and blending requirements of each substance.

Medical Cannabis

In medical cannabis production, mixers play a crucial role in blending emulsions and solutions containing hash oil, CBD, THC, and cannabinoids. High-speed dispersers handle cannabinoid extraction, while multi-shaft mixers are employed for batching products. Ribbon mixers with high throughput contribute to ingredient preparation.

Cosmetics

High-quality mixers are essential for the cosmetics industry to ensure the proper production of sensitive products. Mixers guarantee that cosmetic solutions achieve the correct consistency and texture. Shearing mixers and multi-shaft mixers provide the necessary speed for emulsification, powder wet-out, and particle size reduction.

Food Industry

Mixers are indispensable in every stage of food production, as mixing is a fundamental part of ensuring the quality of food products. Adherence to the standards set by the Food and Drug Administration (FDA) is crucial for any product meant for human consumption. The food industry employs various mixing processes such as dry blending, emulsification, high-speed powder induction, dissolution, dispersion, and high-viscosity mixing.

Plastics and Composites

The rapidly evolving plastics and composites industry relies on efficient mixing for the production of products like polyamides, plastisols, and injection molding formulations. Mixing brings together, blends, or combines materials during the plastic production process.

Inks, Paints, and Coatings

In the ink, paint, and coating processes, which demand precision, mixers play a crucial role. Achieving proper bonding between the mixture and the surface requires precise and accurate mixing. Dispensers, shear mixers, and multi-shaft mixers are pivotal for the success of the ink, paint, and coating processes.

Chemical Industry

Similar to pharmaceuticals, food, and cosmetics, the chemical industry relies on proper mixing for successful product outcomes. Mixing processes, ranging from high to low viscosity, are used for dry blending, particle size reduction, emulsification, homogenization, and powder reduction. Various materials, including abrasives, coal suspension for synfuel processing, flotation reagents, lubricants, oils, and propellants, are blended or mixed to meet specific industry requirements.

The industries listed above represent only a fraction of those relying on mixing technology for their production processes. Essentially, any industry requiring the addition of one substance to another necessitates some form of mixing or blending process. The industrial mixer industry is dynamic, continually growing, and ready to meet the needs of customers with high-quality products.

Benefits of Mixers

The primary goal of any industrial operation is to provide high-quality products at a lower cost and in less time. Industrial mixers are meticulously designed to meet the precise specifications and requirements of each industrial operation. Manufacturers carefully consider the types of materials, homogeneity requirements, and efficiency when selecting mixers capable of meeting specific application needs.

Cost Savings

Mixers are designed to optimize customer needs, ensuring efficient and streamlined production methods. Increased efficiency leads to cost savings on energy, materials, and labor. Durable and long-lasting, mixers require minimal regular maintenance and repair.

Improved Efficiency and Lean Manufacturing

Every manufacturer seeks improved efficiency, and highly engineered mixers contribute to producing higher-quality products in less time. This aligns with the principles of lean manufacturing, as quicker processing of materials reduces the time and energy required for production.

Greater Control

Manufacturers select mixers that provide greater control over the mixing process, meeting the specifications, standards, and requirements of their customers. This customization allows users to blend materials to exacting specifications, ensuring end products meet their needs.

Increased Flexibility and Diversity

Mixers offer the flexibility for users to make changes and adjustments to design and performance as needed. They can be easily adapted for different materials and processes. Mixer manufacturers recognize that no single mixer can meet the needs of every customer, necessitating changes, adjustments, and adaptations to fit specific production processes.

Conclusion

Mixers play a vital role in various industries, adapting to the unique requirements of each application. From adhesives and sealants to the chemical industry, mixers contribute to efficient processing, blending, and treatment of diverse materials. The benefits of mixers include cost savings, improved efficiency, greater control, and increased flexibility. As a dynamic and ever-growing aspect of industrial production, the mixer industry stands ready to meet the evolving needs of its customers with high-quality products.