Robot Sensor : Principle and Its Applications

Automated machines known as robots are engineered for a myriad of functions. Robotics encompasses activities such as welding, assembly, surveillance, rescue missions, and more. Various types of sensors are integrated into robot designs to fulfill specific operational needs, collectively referred to as robot sensors. These sensors are indispensable in robotics, rendering machines responsive and efficient, thereby mitigating uncertainty and enhancing productivity. Without sensors, robots lack perception and awareness. Hence, this article provides an overview of robot sensors, their classifications, and the wide array of applications they serve.

What is a Robot Sensor?

A robot sensor is a device utilized to gauge the state and surroundings of a robot. It relies predominantly on the functionalities of human sensory organs. Therefore, robots require a diverse array of information about their environment to operate effectively, including data related to position, distance, speed, dimensions, orientation, acceleration, pressure, temperature, torque, weight, brightness, and more.

A sensor integrated into a robot enables it to react to its surroundings, facilitating the execution of intricate tasks. Each robot necessitates distinct sensors to govern its actions by acquiring data concerning its position, bodily movements, and individual components.

How Does a Robot Sensor Operate?

The functionality of each sensor primarily hinges on the principle of transduction, which involves converting energy from one form to another. Sensors integrated into robots enable them to dynamically respond to their surroundings. By employing various sensors, robots can perceive and interpret their environment, enabling them to undertake diverse complex tasks.

Robot sensors assess the state and surroundings of robots, transmitting this information to the robot's controller in the form of electronic signals. Consequently, robots require a variety of sensors to regulate their actions effectively.

Features of Robot Sensors

The attributes of robot sensors play a crucial role in selecting the appropriate sensor for various robotic scenarios. Below are some essential characteristics of robot sensors:

1. Accuracy

2. Dead Band & Hysteresis

3. Calibration

4. Repeatability

5. Resolution

6. Linearity

7. Drift

8. Temperature

9. Power

10. Usable Temperature

11. Output Form

12. Storage Temperature

13. Spot Size

14. Reliability

Types of Robot Sensors

Robotic sensors come in various types, as outlined below.

Photodetector

The photodetector is employed to detect light and produce a voltage variance. In robotics, light sensors come in two main types: photovoltaic cells and photoresistors. Photovoltaic cells convert solar radiation energy into electricity and are commonly utilized in the fabrication of solar-powered robots. On the other hand, photoresistors adjust their resistance based on light intensity; when exposed to more light, their resistance decreases. These light sensors are cost-effective, making them readily deployable in robotic systems.

Acoustic Sensors

Acoustic sensors are primarily employed to perceive sound and convert it into an electrical signal. These sensors find application in robots for sound-based navigation. Utilizing such sensors, a robot can be designed to respond to auditory cues. For instance, a robot may be programmed to move to the right upon hearing a single clap and turn left upon detecting two claps.

Thermal Sensors

A thermal sensor serves to detect fluctuations in temperature within its environment. This sensor primarily operates on the principle of voltage variation in response to temperature changes, thus providing an accurate reading of the ambient temperature.

In robotics, these sensors are invaluable for functioning in extreme climatic conditions, whether in icy glaciers or scorching deserts. Various types of temperature sensor integrated circuits (ICs), such as LM34, TMP37, TMP35, TMP36, LM35, and others, are accessible for precise temperature detection.'

Touch Sensor

A touch sensor, also referred to as a contact sensor, finds application in robotics. Its primary role involves detecting alterations in velocity, position, acceleration, torque, or force at the joints of the manipulator and the end-effector. These sensors rely on physical contact to accurately perceive and respond to stimuli, ensuring precise robot operation. They are commonly integrated into various switches such as limit switches, button switches, and tactile bumper switches.

These sensors are extensively utilized in obstacle avoidance systems for robots. Upon detecting an obstacle, the sensor transmits a signal to the robot, prompting it to execute various tasks such as reversing, turning, or coming to a complete stop.

Proximity Sensor

In robotics, a proximity sensor serves to detect objects near the robot and measure the distance between the robot and nearby objects without making physical contact. These sensors rely on magnetic fields to sense such objects, enabling non-contact detection. Proximity sensors are commonly available in two types: IR transceivers, photoresistors, and ultrasonic sensors.

Force Sensors

Force sensors are employed to detect pressure, making them invaluable in robotics as they respond to touch, pressure, and force. These sensors are instrumental in designing robot hands to accurately determine the amount of grip and force required to grasp an object.

Positioning Sensors

Positioning sensors, also referred to as navigation sensors, play a vital role in robotics by enabling robots to detect and determine their positions. Among the commonly utilized navigation sensors are GPS, Localization, and Compass systems.

The GPS (Global Positioning System) is particularly beneficial for outdoor robots as it utilizes maps received from GPS satellites to accurately analyze and determine the robot's location.

Localization Sensor

A localization sensor aids a robot in identifying external elements such as natural landmarks and artificial landmarks, processing their data to precisely determine its position.

Magnetic Compass

The magnetic compass provides directional measurements using the Earth's magnetic field, guiding the robot in the correct direction to reach its destination. These sensors are considerably less expensive compared to GPS systems.

Inclinometers

Inclinometers are employed to gauge acceleration and tilt. Two primary forces influencing the operation of an inclinometer are static and dynamic forces.

Static force, also known as friction between two objects, is utilized to ascertain the precision of a robot's tilt. Dynamic force, representing the amount of force necessary to move an object, is employed to calculate the required acceleration.

Gyroscope Sensor:

Angular Momentum Sensor

An angular momentum sensor, also known as a gyro or gyroscope sensor, is utilized to measure and assist in maintaining orientation based on the principle of angular momentum. It calculates the rate of rotation around a specific axis. This sensor proves invaluable when ensuring that a robot maintains its orientation without relying on Earth's gravity.

IMU Sensor:

Inertial Measurement Unit (IMU)

An Inertial Measurement Unit (IMU) sensor combines the properties of two or more sensors, such as gyroscopes, accelerometers, and magnetometers, to calculate velocity, gravitational forces, and orientation. By integrating multiple sensor functionalities, an IMU provides comprehensive data for precise motion tracking and orientation determination.

Voltage Sensors:

Voltage Range Converters

Voltage sensors are employed to adjust voltage levels from low to high. For example, an operational amplifier operates at a low voltage, amplifies it, and produces a high-voltage output. Even a basic LED can function as a voltage sensor, detecting voltage differences and illuminating accordingly.

Current Sensors:

Current Flow Monitors

Current sensors are utilized to monitor the flow of electric current within a circuit, providing outputs such as current values or proportional voltages. Most of these sensors produce an analog voltage output ranging from 0V to 5V, which can be further processed with the assistance of a microcontroller.

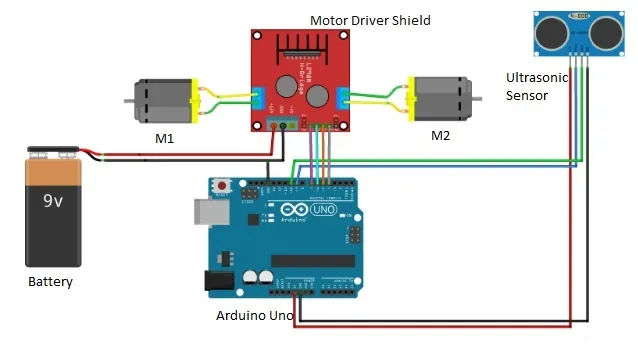

Floor Cleaning Robot using Ultrasonic Sensor & Arduino Board:

Automatic Home Cleaning Robot

The primary objective of this project is to develop an autonomous home cleaning robot capable of cleaning entire rooms by detecting, avoiding, and navigating around obstacles until the entire space is cleaned. Equipped with a brush, the robot efficiently cleans the room. In this setup, an infrared sensor is used for obstacle detection, while an ultrasonic sensor is primarily employed for fall detection.

The necessary components for building this project include an Arduino UNO R3, a shoe brush, ultrasonic sensor, Arduino Motor Driver Shield, battery, power bank for Arduino power supply, Scotch-Brite scrub pad, computer, and a wheel-driven robot chassis.

Schematic Diagram

Displayed below is the schematic diagram for the Automatic Home Cleaning Robot. This circuit can be easily assembled by connecting the ultrasonic sensor to the Arduino board and affixing the Motor Driver shield onto the Arduino.

The HC-SR04 Ultrasonic Sensor utilized in this setup offers stable and highly accurate distance measurements. It is capable of measuring distances ranging from 1 inch to 13 feet (2cm to 400cm). This sensor emits an ultrasound signal at a frequency of 40kHz into the air. The distance to an object can be determined based on the time it takes for the ultrasonic wave to return to the sensor. By knowing the time elapsed and the speed of sound, the distance can be calculated using the provided formula.

Wiring Configuration

The circuit connections are as follows: The Trig pin of the Ultrasonic sensor is directly linked to the Arduino's 12th pin, while the Echo pin is connected to the 13th pin. The voltage pin is attached to the 5V pin on the Arduino, and the GND pin of the sensor is connected to the Arduino's GND pin.

Both the Trig and Echo pins facilitate communication between the Arduino board and the ultrasonic sensor. The voltage and GND pins provide power to the sensor, while the Echo and Trig pins enable the transmission and reception of data through the Arduino board.

The motor shield should feature a minimum of two outputs, typically labeled as M1 and M2, and these outputs should be linked to two motors. Connect the battery and power bank to the Arduino and motor shield respectively to power the system.

Program

```cpp

#include <AFMotor.h>

#define trigPin 12

#define echoPin 13

AF_DCMotor motor1(1, MOTOR12_64KHZ);

AF_DCMotor motor2(2, MOTOR12_8KHZ);

void setup() {

pinMode(trigPin, OUTPUT);

pinMode(echoPin, INPUT);

}

void loop() {

long duration, distance;

digitalWrite(trigPin, LOW);

delayMicroseconds(2);

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

duration = pulseIn(echoPin, HIGH);

distance = (duration/2) / 29.1;

if (distance < 20) {

motor1.setSpeed(255);

motor2.setSpeed(0);

motor1.run(BACKWARD);

motor2.run(BACKWARD);

delay(2000); // Adjust this value according to the robot's turning behavior.

} else {

motor1.setSpeed(160); // Adjust speed for optimal robot performance.

motor2.setSpeed(160);

motor1.run(FORWARD);

motor2.run(FORWARD);

}

}

```

To begin, install the Adafruit Motor Shield Library to control the two motors. As the L293D motor driver shield is utilized, download the motor Library and include it in your Arduino IDE library folder.

Copy the provided Arduino code into the Arduino IDE and ensure your Arduino board is connected to the computer. Choose the appropriate port within Tools or Port and click the upload button.

Test the room cleaning robot. If the rotation speed seems too slow or too fast, experiment with the delay values to achieve optimal results.

Advantages:

- Improves product quality

- Enhances application accuracy

- Expands the range of robotic applications

- Increases workforce safety

- Fast response time

- Long sensing range

- Cost-effective

- Resilient to harsh environments

- Simple installation process

- Highly predictable

Disadvantages:

- Requires physical contact with the target

- Susceptible to contact bounce

- Detection range affected by color and reflectivity of objects

- Sensitivity to drastic environmental changes

- Vulnerable to temperature fluctuations

The usage of sensors in robotics encompasses various applications:

1. Estimation of Robot Condition and Environment: Robot sensors are primarily employed to gauge the condition and surroundings of the robot, enabling it to interact effectively with its environment.

2. Ensuring Smooth Operation: These sensors play a crucial role in ensuring the smooth functioning of robots by providing real-time data about the surrounding conditions.

3. Response to Commands: Robot sensors enable robots to respond promptly and accurately to received commands, facilitating efficient operation and task completion.

4. Facilitating Task Achievement: By comprehending the surroundings, sensors assist robots in determining factors such as object proximity, temperature, sound, and chemical reactions, allowing them to perform tasks accordingly.

5. Achieving Reliable Solutions: Sensors in robotics are essential for achieving reliable solutions characterized by efficiency, quality, fast response times, accuracy, and cost-effectiveness.

In summary, robot sensors are integral components that contribute to the overall performance and functionality of robotic systems, enabling them to operate effectively in diverse environments and execute a wide range of tasks.

As for the question about sensors used in automobiles, there are various types of sensors employed in automotive systems, including:

- Proximity sensors for parking assistance and collision detection

- Temperature sensors for monitoring engine temperature and climate control systems

- Pressure sensors for monitoring tire pressure and engine oil pressure

- Oxygen sensors for monitoring exhaust gas and optimizing fuel-air mixture

- Speed sensors for controlling vehicle speed and monitoring wheel rotation

- Acceleration sensors for detecting sudden changes in vehicle speed or direction

- Light sensors for automatic headlights and interior lighting control

- Position sensors for throttle position, steering angle, and gearbox position detection

- Gas sensors for detecting pollutants in exhaust gases

- Rain sensors for automatic windshield wiper control

- Anti-lock braking system (ABS) sensors for monitoring wheel speed and preventing wheel lock-up during braking.

These sensors play critical roles in enhancing vehicle performance, safety, and efficiency, contributing to the overall functionality and comfort of modern automobiles.

Related Articles

Flexible Sensor Complete Guide

Intelligent Sensors: Definition, Configurations, and Utilizations

Temperature Sensor Selection: Types & Design Techniques Analysis

IR Sensors: Schematic and Priciple Explained