What is Conductivity Sensor?

The exploration of conductivity sensor technology is a crucial focus within the field of engineering studies. Widely applied in human activities and daily life, it plays a fundamental role in evaluating the conductivity of liquids. In both production processes and technological advancements, conductivity sensors serve as indispensable tools for detection and monitoring. Their applications extend to the assessment of industrial process water, human drinking water, marine attributes, and the qualities of battery electrolytes.

Varieties of Conductivity Sensors

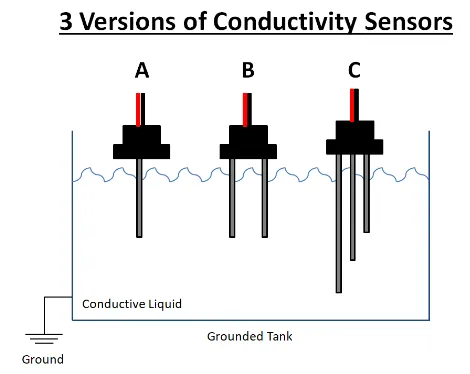

Conductive sensors, categorized by distinct measurement principles, encompass electrode-type conductivity sensors, inductive conductivity sensors, and ultrasonic conductivity sensors.

The electrode-type conductivity sensor gauges conductivity through the resistance measurement method, utilizing the principle of electrolytic conduction. In this process, the conductivity measurement electrode functions as a complex electrochemical system. Meanwhile, the ultrasonic conductivity sensor determines conductivity based on alterations in ultrasonic waves within the liquid. Among these, the electrode-type and inductive conductivity sensors find widespread application.

Electrode-type Conductivity Sensor

Present State and Traits of Two-Electrode Conductivity Sensor Technology

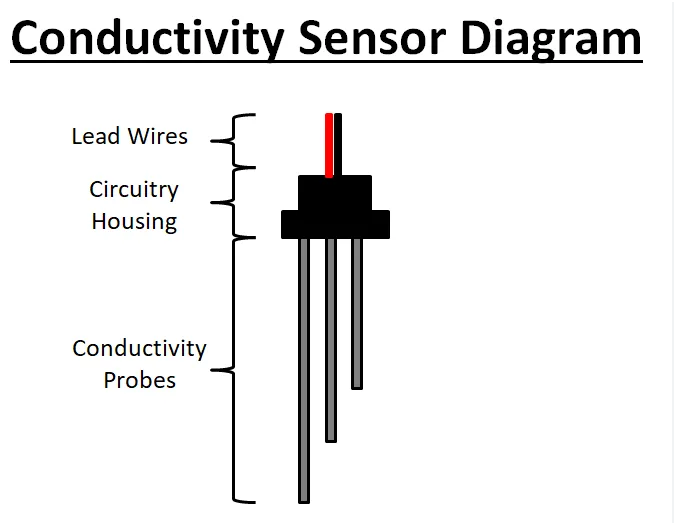

The two-electrode conductivity sensor comprises a pair of electrodes subjected to a constant voltage. Alterations in liquid resistance within the conductivity cell result in a change in the measuring electrode's current, adhering to Ohm's law, and conductivity is employed in lieu of resistivity. This facilitates the representation and measurement of the liquid's electrical conductivity by utilizing electrical conductivity in the metal. The measurement range for the two-electrode conductivity sensor is presently 0-20000 S/cm, with distinct cell constant ranges: 0.01/cm with a measurement range of 0-20 S/cm, 0.1/cm with a range of 0.1-200 μS/cm, and 1.0/cm with a range of 10-20,000 μS/cm.

Typically, the electrode of an electrode-type conductivity sensor comprises two flat electrodes, determining the electrode constant through the facing area and distance of the electrodes. While this type of electrode exhibits a simple structure and manufacturing process, it faces challenges such as the edge effect of the electric force line and complexities in calculating the region facing the electrode and electrode spacing. A common solution is a 0.0100 mol/L potassium chloride standard solution. Improvements to the flat electrode involve the application of the conductivity cell principle, leading to the development of cylindrical electrodes, point electrodes, wire electrodes, composite electrodes, among others.

Features of the electrode-type conductivity sensor include:

1) simplicity in structure and manufacturing;

2) straightforward subsequent processing circuit and implementation;

3) exceptional measurement accuracy;

4) user-friendly operation.

Status and Traits of Four-Electrode Conductivity Sensor Technology

The four-electrode conductivity cell incorporates two current electrodes and two voltage electrodes. The current electrodes align coaxially with the voltage electrodes, allowing the liquid to traverse the space between the current electrodes during measurement. Both ends of the current electrodes receive an AC signal, creating an electric field in the liquid medium. The two voltage electrodes generate a voltage to maintain a constant voltage between them. The liquid conductivity exhibits a linear connection with the current through the two electrodes.

Li Jianguo, from the China National Ocean Technology Center, conducted R&D on the open four-electrode conductivity sensor for marine research. He successfully developed a seawater conductivity sensor with a measurement range of 0-65 mS/cm, meeting international standards with advanced precision of 0.007 mS/cm.

The mature four-electrode conductivity sensor has a measuring range of 0-2 S/cm with varied measurement ranges for different cell constants. Key properties include: 1) Separation of current and voltage electrodes, driven by a constant current source, eliminating polarization impedance effects; 2) High sensitivity and pollution resistance; 3) Applicability for long-term on-site measurement due to its ultra-micro structure, ample diversion space, and low distance.

Application areas of electrode-type conductivity sensors encompass human drinking water quality monitoring, industrial water quality monitoring, battery electrolyte density monitoring, electrolytic oxygen and hydrogen production devices, ocean measurement, marine resource survey, and marine environment monitoring.

Key technologies for electrode conductivity sensors involve eliminating electrode polarization effects, mitigating capacitive effects, and designing multi-electrode conductivity cells with symmetrical electrode pairs.

Future development trends include multi-electrode and micro-electrode configurations, integration with single-chip and micro-system technology for automation, improvement of excitation signal shape, and optimization of excitation sequences for enhanced measurement data independence.

Advancements in electrode materials include exploring novel materials like conductive ceramics and titanium alloys, alongside traditional materials such as platinum, stainless steel, copper, and silver.

Inductive Conductivity Sensor

Status and Traits of Inductive Conductivity Sensor Technology

Conductive sensing through the inductive conductivity sensor relies on electromagnetic induction. The induced voltage in this sensor is directly proportional to the liquid's conductivity within a specific range, where the excitation voltage remains constant. Notably, electrode polarization and contamination concerns are eliminated as the sensor doesn't directly touch the liquid. However, its use is limited to high-conductivity liquids, with a measuring range of 1000-2000000 S/cm.

Distinctive features of the inductive conductivity sensor include:

1) Outstanding anti-pollution and corrosion resistance;

2) Absence of electrode polarization or capacitance effects, suitable for high-conductivity liquids;

3) Simple and user-friendly structure;

4) Straightforward manufacturing process.

Applications of inductive conductivity sensors are prevalent in measuring and detecting high-conductivity liquids, including ocean development and research (seawater salinity measurement), domestic and industrial wastewater quality monitoring, chemical manufacturing processes (analyzing single-component solution concentrations), and measuring the concentration of strong acids and alkalis.

Key technologies for inductive conductivity sensors include aligning excitation and induction coils, optimizing excitation voltage and frequency for sensitivity and linearity, and miniaturizing the detector by adjusting coil diameter and turns.

Future trends in the development of inductive conductivity sensors include a focus on sensor miniaturization, enabled by advancements in material processing and preparation technology. Integration with single-chip microprocessors and microsystem technology aims to automate conductivity measurement, enhancing controllability of the excitation signal for improved accuracy and linearity.

Related Articles

Intelligent Sensors: Definition, Configurations, and Utilizations