What Is a Rheostat? Function, Types & Electrical Applications

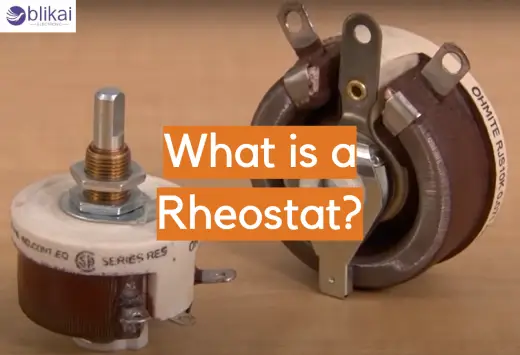

Introduction to Rheostats

A rheostat is a variable electrical resistor used in controlling current flow in a branch. It has been widely employed in places where there is a need to expose it to variable resistance but not switch the circuit. In contrast to fixed resistors, a rheostat can vary resistance smoothly, giving it value in tuning and calibration applications and in manual control. Rheostats are almost like potentiometers, though they are usually only two-terminal devices with a fixed and sliding contact, and are concerned not with voltage division, but with control of the current flow.

How Does a Rheostat Work?

A rheostat works by varying the distance that electric current flows through a resistive path. It is a resistive wire or a track plus a movable contact called a wiper. As the wiper moves along the resistive element, it varies the practical resistance in the circuit. Under conditions when the wiper is close to the input terminal, the resistance will be low and the amount of current will be large. Once it is moved, it becomes more resistant, causing a lower flow of current. This rule refers to Ohm's Law (V = IR), in which resistance has a direct influence on current.

Types of Rheostats

Two classes mostly define rheostats according to their specifications and construction features. These are the main forms:

1. Rotary Rheostats

Rotary rheostats. In rotary rheostats, resistance is varied using a knob or a slowly rotating shaft. These are the most typical ones and the best when a constant and/or frequent adjustment is necessary. The resistive element is usually circular, and the wiper is moved over the resistive element as the shaft rotates.

2. Linear Rheostats (Slide Rheostats)

Linear rheostats use a resistive straight line where a contact is moved across it. They can be frequently seen in laboratory and training situations that need exact manual dexterity. They are larger than rotary types, but permit visual control.

3. Preset Rheostats

They are also referred to as trimmers because they are rheostats that are adjusted when not being changed regularly. They are normally small and are employed within PCBs, where the circuitry will be calibrated when manufacturing them or when repairing them. A screwdriver carries out alignment.

4. Wire-Wound Rheostats

Wire-wound rheostats are resistive wire (usually nichrome) wound over an insulating core. They are capable of high power and are commonly applied in heavy-duty or industrial applications, where heat dissipation is important.

5. Tapered Rheostats

These are wire-wound types, but at specialized ones where the density of the winding is not constant along the length of the resistive track, making it possible to adjust the resistance non-linearly. They are put to good use under circumstances where the application requires variable resistance at a non-uniform rate.

6. Digital/Programmable Rheostats

Although conventionally analog, newer rheostats could incorporate digital connectors to allow control by a computer or a microcontroller. These provide accurate and repeatable settings of the resistance and are becoming more frequent in automatic systems.

Key Electrical Applications of Rheostats

Applications of rheostats are prevalent in the domains of electrical, electronic devices that require the sensitive instrument to regulate currents. The fact that they could increase or decrease resistive value without breaking the circuit means that they are perfect when such a skill is necessary in a real-time manual scenario. Some of the most popular and influential uses are presented below:

Light Dimming Control: In incandescent light, Dimming control, traditional rheostats were used to control brightness. The higher the resistance, the lower the current going to the bulb and hence a darker light. Rheostats are also still used in specialised or low-voltage lighting systems where high-accuracy analogue control is preferred, whereas triac-based dimmer systems tend to be used in modern dimmers.

DC Motor Speed Regulation: Rheostats are commonly used in regulating the speed of brush-based motors. They offer the ability to vary the speed of the motor that can be adjusted according to the current provided to the motor, providing smooth changes in speed, not requiring complicated electronics. This is most practice in small machines, model trains and lab-scale experiments on motors.

Heater and Temperature Control: Rheostats may be used to control the power fed to a heating device as in electric heaters, soldering irons, and laboratory heating plates. With the resistance a higher amount of current will not occur, thus the heat output will be reduced. This renders rheostats useful in a situation where manual control of temperature has to be undertaken.

Testing and Prototyping Circuits: Rheostats can find frequent use when prototyping and testing the behaviour of a circuit with changing load conditions in research and development labs. They become invaluable in prototyping where you may need a precise response in current eg or resistance to verify the design tolerance or to match a working situation.

Audio and Signal Equipment: Also in audio applications, potentiometers are preferred over rheostats in control, but where high power signals need to be adjusted along their path, rheostats are used. As an example, the gain of power amplifiers, or the intensity of analog signal equipment.

Battery Load Testing: When doing maintenance and quality control of batteries, the rheostats can be used as a variable resistive load to control how batteries are discharged at a controlled rate. This gives a technician the opportunity to observe the voltage drop, capacity, and thermal characteristics of varied current loads.

Welding Machines and Industrial Controls: Older welding machines or furnaces, as well as some heavy-duty industrial systems, use rheostats to control the flow of power. Wire-wound rheostats are selected on the grounds of high power-handling and resistance to wear in such applications.

Rheostat vs Other Variable Resistors

While rheostats and potentiometers are both variable resistors, their usage differs significantly:

|

Feature |

Rheostat |

Potentiometer |

|

Number of Terminals |

2 (input and wiper) |

3 (input, output, and wiper) |

|

Main Function |

Vary current |

Divide voltage |

|

Typical Applications |

Motors, heaters, lamps |

Audio controls, sensors |

|

Circuit Connection |

In series with load |

Parallel as voltage divider |

|

Power Handling |

Higher |

Lower |

The rheostats are not suited well to signal-level applications, with well-matched potentiometers being more suited.

Selection Tips and Usage Considerations

When choosing a rheostat for a specific application, consider the following:

- Power Rating: Ensure the rheostat can handle the maximum power (watts) dissipated during operation. Wire-wound rheostats are ideal for high-power environments.

- Resistance Range: Select a resistance value that allows adequate control over the desired current range.

- Form Factor and Mounting: Choose between rotary or linear styles depending on interface needs, and verify compatibility with panel or PCB mounting.

- Durability: Look for rheostats with rugged construction if used in harsh environments.

- Safety: Never exceed the voltage or current ratings to avoid overheating or failure.

Conclusion

Rheostats continue to play significant roles in electrical and electronic systems that need variable resistance. They may be programmed to control lighting and motor speeds for heat and circuit testing, and many more non-aged applications. It is important to understand their working and selection of an appropriate type as important factors in conducting circuit performance and permanency in an electrical design.

FAQs About Rheostats

What is the difference between a rheostat and a potentiometer?

The rheostat is usually a 2 lead device to regulate the current by changing the resistance in series with a load. A potentiometer, however, is a 3 terminal resistive device, which can be used as a voltage divider. The rheostats are better suited into high-power applications and the potentiometer is better suited in low-power signal control.

Can a potentiometer be used as a rheostat?

Yes, it is possible to always create a rheostat of two terminals only (just two): first one end terminal and second wiper. Not all potentiometers are rated to handle the current levels usual with rheostat applications, so first, power handling must be checked.

What are typical resistance values for rheostats?

Rheostats can be made to have a very large change of resistance value, but typically several ohms to several kilo-ohms. Its correct value will vary with the use, the maximum current that has to be variable and the power to be dissipated.

Where are rheostats commonly used today?

Although digital control systems have replaced rheostats in many areas, they are still used in:

- Educational labs

- Industrial motor control

- Heater control systems

- Circuit testing and load simulation

Why are rheostats not commonly used in modern dimmer switches?

Triacs or PWM (Pulse Width Modulation) are used in modern dimmers which are more efficient and do not produce as much heat. Energy that is not flowing out due to rheostats is released as heat and thus rheostats are not practical in large-scale or continuous dimming.

What materials are used in rheostats?

More recent dimmers are more efficient and require less heat, and either rely on a triac or PWM (Pulse Width Modulation) circuit. Rheostats are inefficient dimmers since they use up surplus energy in the form of heat, thus unsuitable for large-scale and continuous dimming.

Some images are sourced online. Please contact us for removal if any copyright concerns arise.

What is an Mechanical Comparator?

CR1616 vs CR2025 Battery

What is Hartley Oscillator: Circuit, Working, and its Applications

ATMEGA128A-AU MicroChip: Features, Applications, and Datasheet

74ACT818SPC:Description,Features,Application and FAQ

Arduino Mega 2560 Size and Specifications

AD698APZ Analog Devices: Features, Applications, and Datasheet

What is the LM393 IC?All You Need to Know

Explanation of the Working Principle of Photodiodes

EEC2E805HQA404 Nichicon: Features and Applications