FGA15N120 IGBT: Pin Configuration and Applications

In the FGAxxN120 series, Fairchild Semiconductor offers a variety of IGBTs. Among these NPT IGBTs is the Fairchild FGA15N120 IGBT. Transistors with this feature include low saturation voltage & very low switching loss, so they are suitable for designing low voltage circuit switching drivers that are extremely efficient. A FGA15N120 IGBT includes a 15A collector-emitter voltage (VCE) at 125°C, and it is denoted by FGA15N120 after the prefix FGA. A brief description of the features, the pin configuration, and the applications of the FGA15N120 IGBT is presented in this article.

What is FGA15N120 IGBT?

An IGBT with a gate voltage of 15V, the FGA15N120 is designed for high-power applications. With its high input impedance and low saturation voltage, the FGA15N120 combines the benefits of a MOSFET and a bipolar transistor to provide efficient switching and amplification. Induction heating, motor drives, and power inverters are among the applications where it is especially useful. Industrial and commercial applications require a device that can handle a maximum collector-emitter voltage of 1200V and continuous collector currents of 30A.

Featuring fast switching speeds and low conduction losses, the FGA15N120 enhances high-frequency performance. By allowing high voltages while minimizing on-state voltage drops, the system reduces power dissipation and improves efficiency. The IGBT also features built-in protection mechanisms such as short-circuit protection, which ensures the device is highly reliable and durable in various high-power applications. Engineers seeking efficient and reliable performance in power electronics systems prefer the FGA15N120 for these reasons.

How to Use FGA25N120

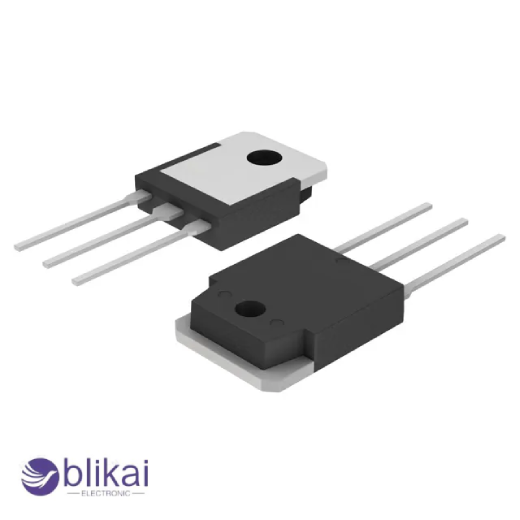

Careful attention must be paid to the pin configuration, proper driving methods, and protective measures when using the FGA25N120 IGBT. Three pins are included in the TO-247 package: the collector, gate, and emitter. It is usually the load that connects the collector to the power supply, while the ground or negative side of the supply connects the emitter. IGBT gates are controlled by gate drivers via gate resistors, which are connected to gate drivers. It controls the switching speed by limiting gate current and resisting gate current up to 100 ohms.

An IGBT should be operated efficiently with a gate driver IC capable of providing the required voltage and current. To fully turn on the IGBT, the gate driver must supply a sufficient drive voltage, usually around 15V. To protect against high voltages and noise, it is crucial to isolate the gate drive circuit from the control logic circuit. To prevent voltage spikes caused by inductive loads, a flyback diode must also be included across the load. For reduced switching stress and to dampen voltage spikes, a snubber circuit should also be placed across the collector and emitter.

IGBTs like the FGA25N120 require proper heat management. Heat is dissipated and the junction temperature is maintained within safe limits with an IGBT mounted on a heatsink. Thermal paste improves thermal conductivity and enhances heat dissipation between an IGBT and its heatsink. In order to extend the device's lifespan, it is essential to maintain proper heat management.

PWM signals are often used to drive the gate of the IGBT for applications such as motor drives and inverters that require variable power control. IGBTs' switching speed characteristics play a critical role in selecting the appropriate switching frequency. Gate drivers may need to operate at a faster speed and cooling solutions may have to be more effective at handling higher switching frequencies. During turn-ons and turn-offs, it is also advisable to incorporate current-limiting circuits or components to prevent excessive current flow through the IGBT. In high-power switching applications, the FGA25N120 IGBT can effectively be used by following these guidelines.

Pin Configuration

IGBTs are commonly packaged in TO-247 packages due to their high power handling capability and ease of mounting. The FGA15N120 IGBT is housed in a TO-247 package. TO-247 packages have three pins: Collector (C), Gate (G), and Emitter (E). IGBTs must be integrated correctly into a circuit by understanding their pin configuration. Each pin is described in detail below:

Collector (C)

-

Function: Collector pins are the IGBT's main terminals for carrying current. The collector and emitter of the IGBT flow current when they are turned on.

-

Connection: It is typically the positive supply voltage or the load that is connected to the collector in most applications. This pin is suitable for switching high-power loads due to its high voltage and current handling capabilities.

-

Physical Position: The collector is usually the left pin on the IGBT when looking at it with the leads facing down.

Gate (G)

-

Function: Switching of the IGBT is controlled by the gate pin. Current flows between the collector and emitter when a voltage is applied to the gate (relative to the emitter).

-

Connection: The gate driver circuit connects the gate to the IGBT to provide voltage and current to turn it on and off. The gate resistor controls the switching speed and limits the peak gate current by connecting in series with the gate.

-

Physical Position: The gate is located on the middle pin of the TO-247 package. By properly driving the gate, switching losses are minimized and efficient operation is ensured.

Emitter (E)

-

Function: Current flowing through the IGBT returns to the emitter pin. By turning on the IGBT, the circuit is completed.

-

Connection: Most power supplies connect the emitter to ground or the negative side. An emitter resistor can provide feedback to protection circuits, especially in high-frequency applications.

-

Physical Position: When viewing the TO-247 package from the front and the leads down, the emitter is the pin to the right.

Applications

Motor Drives

A high current and voltage handling capacity makes the FGA15N120 IGBT ideal for motor drive applications. A large motor drives large equipment such as conveyors, pumps, and fans in an industrial setting. Servo drives and variable frequency drives (VFDs) that require precise control of motor speed and torque are ideal applications for the IGBT's ability to switch large currents with high efficiency. For motor drive systems to operate efficiently and reliably, the FGA15N120 has fast switching characteristics that minimize power loss and heat generation. Further, its 1200V rating ensures robustness and reliability in industrial motor applications, where high voltages are often encountered.

Inverters for Renewable Energy Systems

IGBTs such as the FGA15N120 are crucial components in renewable energy systems, such as solar panel and wind turbine inverters, that convert DC power to AC power for the grid or local consumption. In order to optimize the performance and return on investment of renewable energy installations, the IGBT's high efficiency and fast switching speed maximize energy conversion efficiency. In both commercial and residential renewable energy systems, IGBTs are ideal due to their ability to handle high voltages and currents. Their power conversion processes are also reliable and efficient. Further, its robustness ensures long-term reliability in harsh outdoor environments often associated with renewable energy installations.

Induction Heating

With its high power handling and fast switching capabilities, the FGA15N120 IGBT is an excellent choice for induction heating systems. In addition to metal hardening and welding, these systems can also be used in cooking appliances and cooking equipment. Faster heating times and more consistent temperature control can be achieved with the IGBT, which allows efficient and precise control of high-frequency currents. Induction heating applications require high current levels due to the device's high current capacity. In addition, the high voltage rating ensures that the IGBT can withstand the high voltages commonly encountered in these systems, ensuring reliability and increasing heating efficiency.

Uninterruptible Power Supplies (UPS)

During mains power failures, the FGA15N120 IGBT provides critical backup power through uninterruptible power supplies (UPS). To convert DC power stored in batteries into AC power for connected loads in UPS systems, IGBTs are used in the inverter stage. IGBTs minimize power loss and ensure rapid response times during power transitions due to their high efficiency and fast switching speed. During power outages, this ensures that sensitive equipment like servers, medical devices and communication systems remain powered. Providing reliable protection for critical loads with its high voltage and current handling capabilities, the FGA15N120 can be used in both small- and large-scale UPSs.

Welding Equipment

An IGBT such as the FGA15N120 protects arc welding equipment from excessive power. Suitable for welding applications that require precise control of the welding arc, it is capable of switching large currents efficiently. The fast switching capabilities of the IGBT help to control weld quality and reduce spatter by accurately modulating the welding current. In harsh welding environments, the FGA15N120 provides reliable performance due to its rugged construction. Further, its high voltage rating makes it more durable and reliable due to its protection against voltage spikes during welding.

Power Factor Correction (PFC)

The FGA15N120 IGBT is used in power factor correction circuits to improve power factor and reduce electricity costs. By adjusting the current waveform to align with the voltage waveform, IGBTs are used in PFC applications in order to reduce reactive power. A high-power industrial and commercial application requires the power factor correction of the FGA15N120, which is highly efficient and has a fast switching speed. IGBTs reduce electrical infrastructure loads and increase system capacity by improving the power factor. A valuable component in modern power electronics, the FGA15N120 is able to handle high voltages and currents in demanding PFC applications.

Wrapping UpThe FGA15N120 IGBT stands out as a highly versatile and robust component ideal for high-power applications.

High-power applications benefit greatly from the FGA15N120 IGBT's versatility and robustness. Induction heating and welding equipment are among the industries that benefit from its capabilities to handle high currents and voltages. It can also switch at high speeds and produce efficient results. Electronic systems are enhanced through the use of the FGA15N120's reliable and efficient operation and reduction of power losses. Providing precise control and enduring harsh conditions, it is a crucial component of modern power electronics. Engineers and designers seeking optimal power management and efficiency can rely on the FGA15N120 IGBT for industrial, commercial, or renewable energy applications, due to its exceptional performance and reliability.

Related Articles

What is Discrete Semiconductors: Overview, Applications, and Benefits

MBRS340T3G Semiconductor: Features, Applications and Datasheet

The Interconnection Between Semiconductors and Cybersecurity

Deciphering Variances: Semiconductor vs Microchip vs Integrated Circuit

IRF3205 MOSFETs: Applications, Features, and Equivalent

Impact of IRF3205 MOSFET on Power Electronics: Advancements and Applications

2N5088 Transistor : Pinout, Equivalent, Datasheet

2N5551 Transistor:Features,Applications and Pinout

Phototransistor : Circuit Pinout & Principle

What is Thin-Film Transistor(tft) monitors? All explained

Transistor Series Voltage Regulator:All You Need to Know

Junction Field-Effect Transistors: Principles, Applications, and Advantages

Insulated Gate Bipolar Transistor:Features and Pinout

PNP Transistor? Construction, Working & Applications