Flexible PCB Solutions: Design Tips, Components & Applications

Introduction

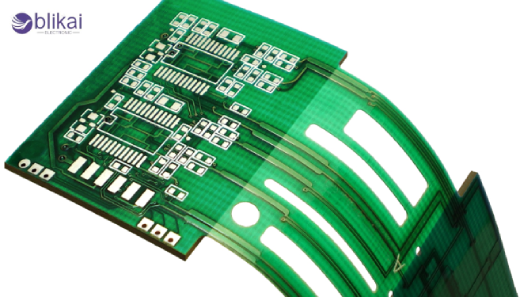

Flexible PCBs or flex circuits are an innovative element in the electronics world today. Contemporary PCBs are flexible and can be bent, folded and twisted to fit into small areas, unlike the customary PCBs that are rigid. Having a high level of lightweight, durability, and flexibility, they can be used in applications as small as a smartphone and as big as a wearable device. With the increasing demand for miniaturized and high-performance electronics, the need to be able to find flexible PCB solutions is gaining importance among designers and manufacturers in search of good and efficient circuit integration.

What Is a Flexible PCB?

A flexible PCB is a printed circuit board designed to bend or flex without compromising electrical performance. It can be usually composed of thin insulating materials, copper trace material and protective coats. The flexible PCBs are compared to rigid PCBs which are hard and incapable of bending and rigid-flex PCBs which consist of a blend of hard and soft components. Polyimide (PI) and polyethylene terephthalate (PET) are frequent substances, which are incorporated into the creation of flexible PCBs, and both of them are best suited to provide thermal stability and mechanical solidness.

Key Components of Flexible PCBs

Copper Traces

Although it is not the central conductive trace, the major conductive pathways in a flexible PCB are copper traces, which are used to deliver signals and power among components. Their thickness, width, and pattern should be well formulated in order to avoid any harm during bending or folding. Well-designed copper traces preserve the integrity of signals and minimize the possibility of a circuit failure, even after a long time of mechanical stresses.

Insulating Layers and Substrates

The insulating layers are polyimide (PI) or PET that is usually electrically isolated and mechanically supported by the copper traces. These are substrates that are necessary in maintaining thermal stability and long term durability, in such a way that there is flex PCB bending without cracking and delaminating.

Protective Coatings and Solder Masks

Flexible circuits are covered with protective coating and solder mask to prevent dust, moisture, chemical corrosion and abrasion. They are also useful in alleviating short-circuiting and enhancing the reliability of soldering, which makes the PCB more robust to extended and strenuous environments, as well as increases its service life.

Connectors and Vias

Layer interconnection and connection with outside components require the use of connectors and vias. Flexible PCBs often use specialized flexible connectors that can tolerate repeated bending, while vias allow signals to pass between different layers without compromising flexibility or performance.

Design Tips for Flexible PCBs

In order to have a flexible PCB, it is necessary to be particularly careful with the design in order to be durable and disposable:

Layout Strategies: Sharp bends are to be avoided but soft curves and 0.5-1 mm radius of a bend is the norm.

Trace Width and Spacing: Traces should not be excessively narrow or excessively wide to be able to carry current and at the same time be able to bend and be flexible without cracking.

Thermal Management: Polyimide can handle high temperatures, but designers must consider heat dissipation for high-current applications.

Material Selection: Choose substrates and adhesives that balance flexibility and mechanical strength.

Testing and Simulation: Simulation is performed to bend and fold to determine possible stress points to avoid failure in a real-world application.

Advantages of Flexible PCBs

Space and Weight Reduction

The flexible PCBs are very flexible, portable, and are very lightweight as well, therefore, designers can design small and limited gadgets. By replacing bulky cables and connectors, they enable smaller form factors and reduce overall product weight, which is especially beneficial in consumer electronics and wearable devices.

Durability Under Stress

Flex circuits are able to endure vibrations, shocks, and repeated bending without becoming nonfunctional. Their tough materials and designed trace patterns also assure that the PCB will not lose electrical integrity even in automobile, aerospace and industrial applications where mechanical stress is the norm.

Simplified Assembly

Multi- connector and multi-wiring harnesses may be replaced by flexible PCBs which offer the possibility to minimize the complexity of the assembly and the work. Fewer components mean fewer potential points of failure, improving reliability while streamlining manufacturing and maintenance processes.

Enhanced Signal Integrity

Direct connections are made in flexible PCBs that are of shorter length; these minimize the signal path length with minimal electromagnetic interference (EMI) and signal loss. Flex circuits are thus appropriate in products that are high-speed, high-frequency, and sensitive electronic products such as smartphones, medical equipment, and IoT sensors.

Typical Applications of Flexible PCBs

Consumer Electronics

Flexible PCBs find application in smartphones, tablets, cameras and wearables. They are flexible and can be folded, and this allows manufacturers to develop thinner and light, and even ergonomic products. The flex circuits allow the use of compact connections between components, and extensive cables and connectors are avoided, and the signal integrity is also maintained to transmit high-speed data.

Automotive Electronics

Flexible PCBs are part of the dashboard displays and infotainment systems, sensors, and advanced driver-assistance systems (ADAS) in the automotive industry. They provide vibration resistance and thermal stability, which is a guarantee that they will perform well even under extreme working conditions. Flex PCBs are also useful in innovative interior designs having complicated wiring routes within confined spaces.

Medical Devices

Flexible PCBs are used in portable diagnostic devices, wearable monitors, and patient tracking devices used in medical and healthcare devices. Their light and non-rigid nature enables them to monitor patients at all times without causing any discomfort. Moreover, flex circuits are also very reliable and accurate, which is vital in the case of life-saving applications.

Industrial Electronics

Flexible PCBs find applications in robotics, IoT devices, aerospace devices and automated equipment. They are compact, mobile, or prone to mechanical stress, so they are space-saving and can be used in industrial environments. Flex circuits also simplify the wiring and reduce potential points of failure in a more complex assembly.

Challenges and Considerations

Despite their advantages, flexible PCBs present certain challenges:

Cost: The manufacturing of flexible PCBs is, in most cases, more costly than that of rigid PCBs because of material and manufacturing complexity.

Manufacturing Complexity: In order to be reliable, more specific and tighter tolerance must be employed during the manufacturing.

Current and Thermal Limits: Flex circuits are usually thinner, limiting current capacity and heat dissipation.

Environmental Sensitivity: Moisture, temperature fluctuations, and mechanical stress can affect long-term performance.

Future Trends in Flexible PCB Technology

Flexible PCB is under development and this technology is enabled new possibilities in electronics:

Foldable and Wearable Electronics: Foldable smartphones and wearable health monitors are expanding flex PCB applications.

Integration with Advanced Sensors and IoT Devices: Flexible circuits facilitate compact, connected devices for smart homes and industrial automation.

Stretchable and Hybrid Circuits: Stretchable and Hybrid circuits are being developed to satisfy the wearable devices and medical devices of the next generation.

Such trends indicate that flexible PCBs will carry on with the role of innovative electronics design in the coming years.

FAQ

What materials are used in flexible PCBs?

Flexible PCBs primarily use polyimide (PI) and polyethylene terephthalate (PET) as substrate materials. These are highly thermal stable materials, which are mechanically and reliably flexible in the long-term of bendable circuits.

How do flexible PCBs differ from rigid PCBs?

The flexible PCBs can bend, fold and twist to suit compact designs unlike the rigid PCBs which are not flexible and can never bend or fold. The hybrid uses of rigid-flex PCBs utilize both types.

How are flexible PCBs tested for durability?

The flexible PCBs are subjected to mechanical bending, thermal cycling and electrical continuity tests to enable them to work when flexing in repeated as well as environmental conditions.

Conclusion

The versatility, durability and compactness of PCBs has been used to reshape the electronics industry by creating flexible PCBs that are versatile. Flex circuits are used in making small consumer devices as well as complex automotive and medical devices, making it possible to design a system that is innovative and does not sacrifice its functionality. After good design guidelines, the choice of the right components, and knowledge of the needs of the application, engineers can make full use of flexible PCB solutions in terms of reliability and high-performance electronics.

Some images are sourced online. Please contact us for removal if any copyright concerns arise.

What Is CBB61 Capacitor - Function and Applications

The Ultimate Guide to CR1220 Battery

ESP32 vs ESP8266: Which One Should You Choose?

2N3904 vs 2N2222:What You Need to know

How Does a Single Phase Motor Work?

What are Audio Transformers for?

Semaphore in Embedded System

What is Conductivity Sensor?

Different Types of Mixers

Arduino vs. Raspberry Pi: An In-Depth Contrast