What is a Ceramic Potentiometer & How Does It Work?

Have you ever found yourself wondering how your stereo system achieves such precise volume control or your car dashboard dimmer can so smoothly adjust brightness? The answer lies within one small yet powerful component, the ceramic potentiometer. In this blog post we'll take an in-depth look into this fascinating device's structure, science behind their operation, and various types available - in other words a ceramic potentiometer will become your new best friend!

What are Ceramic Potentiometers?

Ceramic potentiometer is a variable resistor made of ceramic as its base material. The primary function of a ceramic potentiometer is to regulate the electrical resistance in circuits via manual adjustment. Its ceramic substrate exhibits excellent thermal stability and consistency characteristics; hence, it finds applications at high-temperature places.

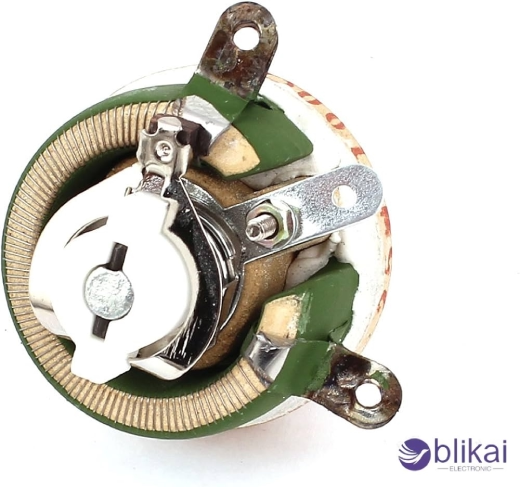

Key Components of a Ceramic Potentiometer

- Ceramic substrate: This provides structural support and thermal stability.

- Resistive track: Conductive material deposited on the ceramic substrate that acts as resistance.

- Wiper: A movable contact that slides along the resistive track.

- Terminals: Connection points for the circuit.

Advantages Over Other Types of Potentiometers

- High temperature resistance

- Excellent stability and durability

- Low noise operation

- Resistance to environmental factors like humidity and chemicals

Common Applications in Electronics

- Industrial control systems

- Audio equipment

- Automotive electronics

- High-temperature sensors

- Precision instruments

Structure and Design of Ceramic Potentiometers

Wiper Mechanism

Ceramic potentiometers require an essential part known as the wiper mechanism to perform precisely controlled resistance adjustments. It is nothing but the sliding contact that slides along an infinite resistive track for fine resistance adjustment. The construction of the wiper mechanisms usually requires a highly durable and reliable material such as beryllium copper alloy or precious metal such as gold.

Resistive Track Composition

Ceramic potentiometer resistive tracks are made up of specially formulated ceramic material. They are created by depositing resistive cermet (ceramic-metal) ink onto ceramic substrates; its composition determines both resistance range and characteristics for potentiometers.

Terminal Connections

Ceramic potentiometers invariably use three terminal connections: that is, two fixed terminals at each end of the resistive track and a wiper terminal. They are normally made of tough materials such as brass or copper to facilitate effective electrical contact and durability.

Housing and Protective Elements

Ceramic potentiometer housings are constructed to protect their internal components from external influences. Housings may be made from materials resistant to high temperatures to improve their ability to withstand harsh environments, and, indeed, some models even go further to include gaskets and coatings to guard against moisture, dust, and contamination.

Working Mechanism of Ceramic Potentiometers

Voltage Division Principle

Ceramic potentiometers operate on the fundamental principle of voltage division. The resistive ceramic track acts as a voltage divider, allowing for precise control of electrical current flow. As the wiper moves along the track, it creates two resistive segments, effectively dividing the input voltage proportionally.

Adjustment Process and User Interaction

The user interacts with the ceramic potentiometer by rotating a shaft or sliding a knob. This mechanical movement translates to the wiper's position on the ceramic track. As the wiper moves, it changes the ratio of resistance between the two segments, altering the output voltage. This simple yet effective mechanism provides intuitive control over various electronic parameters.

Signal Output Variations

The position of the wiper determines the output signal variations. As the wiper moves closer to one end of the track, the resistance in that segment decreases, while increasing in the other. This change in resistance ratio directly affects the output voltage, allowing for smooth and continuous adjustment of the signal. The ceramic material's properties ensure stable and reliable output variations, making these potentiometers ideal for precision applications.

Types of Ceramic Potentiometers

Ceramic potentiometers come in various styles to meet specific application needs. Let's explore three main varieties of ceramic potentiometers.

Linear potentiometers

Ceramic linear potentiometers are distinguished by their consistent resistance change throughout their entire range of motion, with resistance changes proportionately responding to distance traveled on the resistive track by moving a wiper along it. Their linear relationship makes them suitable for applications requiring precise control over wide values, such as volume controls or position sensing in industrial machinery.

Logarithmic potentiometers

Also referred to as audio taper potentiometers, logarithmic ceramic potentiometers feature non-linear resistance changes as their wiper moves. Their resistance varies logarithmically as it goes around, providing gradual initial change followed by quicker rates toward the end. This makes them particularly suited for audio applications as their characteristics more closely mimic our auditory perception of volume changes than linear systems can do.

Multi-turn potentiometers

Multi-turn potentiometers boast increased precision and fine-tuning capabilities over their single-turn counterparts, which offer one rotation coverage for their full resistance range. Multi-turn variants utilize multiple turns instead for more accurate adjustments - perfect for calibration equipment and scientific instruments that demand high levels of precision.

Advantages and Disadvantages

Temperature Stability and Durability

Ceramic potentiometers excel in environments with extreme temperature variations. Their ceramic composition provides exceptional thermal stability, allowing them to maintain consistent performance across a wide temperature range. This durability makes them ideal for use in automotive, aerospace, and industrial applications where reliability is crucial.

Precision and Accuracy in Measurements

A key advantage of ceramic potentiometers is their exceptional precision and accuracy in measurements. Their inherent properties permit fine-tuned resistance adjustments that provide more precise voltage or current control - something particularly valuable in sensitive electronics or measurement devices.

Cost Considerations

Ceramic potentiometers typically offer superior performance at an upfront higher cost compared to carbon or plastic units; however, their long lifecycle makes up for this in the form of reduced replacement expenses or impracticality in high usage applications.

Size and Space Constraints

Ceramic potentiometers tend to be larger and heavier than other varieties, which may pose space restrictions in smaller devices or applications that prioritize portability or lightweight materials. Their larger footprint may make them less suitable for portable electronics; however, their robust nature makes them suitable for industrial settings where size considerations are less of a priority.

Maintenance and Troubleshooting

Common issues with ceramic potentiometers

Ceramic potentiometers, though durable, may experience issues over time. Wear and tear on the resistive track often leads to inconsistent output; dust or debris accumulation impedes wiper movement and accuracy; moisture ingress may cause corrosion damage that corrodes internal components - these issues should all be considered potential concerns when purchasing ceramic potentiometers.

Cleaning and care tips

Regular maintenance cleaning is key for optimal performance of any device, including an ergonomic keyboard. A soft, lint-free cloth should be used to wipe down its exterior; for stubborn dirt use mild solutions like isopropyl alcohol sparingly as too much liquid may seep into your device and become trapped there. Occasionally rotate the shaft through its full range to distribute lubrication and reduce stiffness.

When to replace a ceramic potentiometer

Ceramic potentiometers are known for their long service lives; however, replacement becomes necessary when certain signs arise. If erratic readings, an abrupt resistance change, physical damage to the housing or persistent issues requiring cleaning and maintenance fail to resolve; or when the device no longer fulfills precision requirements of your application; replacement should be considered to ensure continued reliable performance.

Conclusion

Ceramic potentiometers are integral parts of electronic applications, providing precise resistance control with exceptional durability. Crafted using ceramic materials for construction, these devices boast excellent thermal stability and resistance against harsh environments. Understanding their structure, working mechanism and types will enable engineers and enthusiasts to make informed decisions when selecting one for their projects.

Ceramic potentiometers offer many advantages, including their temperature resistance and long-term stability, but it's important to recognize their downsides, including higher costs and potential fragility. Regular maintenance and troubleshooting techniques can extend their lifespan while guaranteeing optimal performance within electronic circuits. By carefully considering both their advantages and drawbacks, you can determine if ceramic potentiometers are a suitable option for your particular use case.

Related Articles

What is a Hybrid Potentiometer? A Simple Guide

MCP41010 Potentiometer: Features and Applications

Potentiometer: Pinout, Symbol, Applications, and Working

10K Potentiometer Pinout: Features Applications and Datasheet