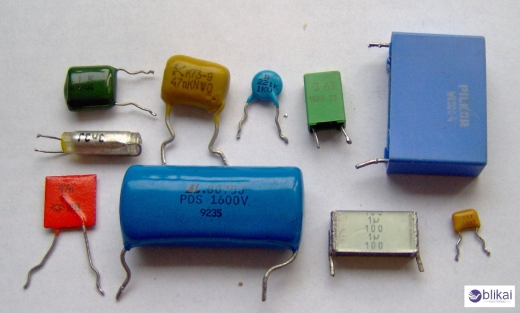

Different Capacitor Types: A Guide

What Is a Capacitor?

Capacitors are nearly always used in electronics. A capacitor is any kind of appliance that will store electricity and will discharge it. It's principally composed of two conductive plates separated by a separating medium known as a dielectric. Due to their capability to charge and discharge electric charges at veritably rapid-fire rates, capacitors find operation in a veritably wide span of circuits-from simple power inventories to veritably sophisticated electronic systems.

How Capacitors Work

Capacitance refers to the capability of the capacitor to store an electric charge when connected to the voltage source. Task of creating a number of electrons on one plate does the work of the electric field, causing an equal charge on the contrary plate to be driven out due to this field. This field possesses stored energy, which is the energy released during the discharging of the capacitor. Capacitance itself is measured in farads( F), which tell how important charge a capacitor can hold.

Key Capacitor Parameters

Several parameters are crucial when selecting and using capacitors:

- Capacitance: the amount of electrical charge able to be stored by a capacitor, measured in farads.

- Voltage rating: the maximum voltage at which the capacitor is able to function safely without internal breakdown.

- Tolerance: the maximum deviation in the nominal capacitance value, generally expressed as percentages.

- Temperature coefficient: the change in capacitance with temperature variations.

- Equivalent Series Resistance (ESR): the internal resistance that results when the capacitor functions.

Electrolytic Capacitors

Aluminum electrolytic capacitors

Aluminum electrolytic capacitors use two conductive and one oxide dielectric layer on the roughened surface of rolled aluminum foil. While having a capacitance value greater than more compact capacitors, the aluminum electrolytic type is generally more economical to manufacture and provides high-voltage power. Their Achilles' heel, however, is the limited usable life due to the drying out of the electrolyte.

Tantalum electrolytic capacitors

The dielectric material is tantalum pentoxide. They generally have much more advanced capacitance per unit volume than aluminum electrolytic capacitors, along with lesser stability over time and temperature. Following this line of logic, they may be more expensive than aluminum electrolytic capacitors, but in numerous operations tantalum should have much better performance.

Advantages and Disadvantages

High capacitance for comparatively low dollars would make electrolytic capacitors good for high voltage applications while good for filtering. However, these units have a specified life, are temperature sensitive, and consist of a polarity which may cause failure unless correctly installed.

Common Applications

Electrolytic capacitors are often found in power supplies, audio circuits, and motor starter circuits. They work excellently in smoothing power supply ripple and coupling audio signals, allowing a high capacity. While aluminum electrolytic capacitors are used in most consumer electronic circuits, tantalum capacitors are used in aerospace and military applications where reliability and stability are required.

Ceramic Capacitors

Types of ceramic capacitors

There are many kinds of ceramic capacitors, each suitable for a specific type of application. The major types are Class 1 (C0G/NP0) and Class 2 (X7R, X5R, Y5V). Class 1 capacitors have high stability and low loss, making them suitable for precision applications. In contrast, Class 2 capacitors provide higher capacitance values in smaller packages and are intended for general-purpose applications.

Advantages of ceramic capacitors

The numerous advantages of ceramic capacitors make them a popular choice in electronics. They provide excellent high-frequency performance, with very low equivalent series resistance (ESR) and high insulation resistance. Their small size and surface mount technology (SMT) compatibility make them highly appropriate for applications where space is limited. Ceramic capacitors are also quite stable over their useful life and exhibit a relatively high thermal tolerance.

Limitations and considerations

Of course, ceramic capacitors have shortcomings, too. They tend to be sensitive to mechanical stress and temperature fluctuations, changes that could lead to variations in capacitance. Class 2, because of their voltage coefficient of capacitance (VCC), changes capacitance values with applied voltage; that is, they lose capacitance when a voltage is applied. In some cases, they can result in acoustic noise in applications as a result of the piezoelectric effect.

Film Capacitors

Polyester film capacitors

Polyester film capacitors, referred to as Mylar or polyester capacitors, are extensively used in various electronic applications. They consist of a thin polyester film, a dielectric material, and two metal foil electrodes. Polyester film capacitors are very stable and have a low dissipation factor and high insulation resistance. They are used when close capacitance tolerances and long-term stability must be achieved.

Polypropylene film capacitors

Polypropylene film capacitors, also called PP capacitors, represent yet another popular family of film capacitors. The use of plastic Polypropylene as the dielectric provides better electrical characteristics than polyester counterparts. They have extremely low dielectric absorption and thus are one of the best counterparts for high-frequency and pulse applications. They also have lower dissipation factors and better temperature stability compared to polyester guidelines.

Ideal uses for film capacitors

Film capacitors provide excellent high stability and low losses with a practical and responsive frequency output. Generally found in audio equipment, power supply units, and motor-run circuits, film capacitors prove best for timing and filtering applications in industrial and automotive electronics. They can bear high voltage and current, which makes them ideal for power factor correction and snubber circuits' use in power electronics. Furthermore, they are preferable when considering self-healing properties; the lifespan of electronic devices put under drastic environmental conditions is prolonged this way.

Supercapacitors

How supercapacitors differ from traditional capacitors

Supercapacitors, called ultracapacitors, progress in energy storage technology. Unlike regular capacitors, supercapacitors use a different mechanism to store energy. They utilize a double layer of charge formed between the interface of an electrode and an electrolyte to achieve a much higher capacitance and energy density.

Energy storage capabilities

Supercapacitors can store much higher levels of energy, anywhere from 10 to 100 times greater than normal capacitors per unit volume or mass. Because of their high energy density and their ability to charge and discharge about a thousand times more quickly than batteries, they are more than qualified for applications where bursts in rapid power are essential.

Applications in renewable energy

Supercapacitors are gradually becoming popular in the efficient production of renewable energy systems. They facilitate the buffering of power fluctuations from solar and wind installations, support backup power to supply power even to small interruptions, and also help recovery of energy when regenerative braking is on in electric vehicles. Also, their infinite lifecycle and temperature-tolerant range of operation are of great help in short, demanding applications.

Choosing the Right Capacitor

Factors to consider

There are several matters to consider when choosing a capacitor. You will need to be aware of voltage rating, capacitance value, and temperature range, which are usually very important to applications in extreme environments. Then, there is the actual size and form factor, which must fit within the available space in your circuit. These requirements will assign the capacitor function with respect to frequency response for AC applications and leakage current development for power-sensitive designs.

Matching capacitor types to specific needs

Different capacitors are advisable in other applications. Electrolytic capacitors are suitable for high-capacitance and low-frequency applications, like power supplies. Ceramic ones work great in high-frequency applications and decoupling. Film capacitors are stable and are a good choice for audio circuits. Supercapacitors are ideal for energy storage and backup power systems.

Cost considerations

When component selection is concerned, cost is always a factor to consider. Although ceramic capacitors are usually inexpensive, specialized types, such as high-voltage film capacitors, may be relatively more expensive. Consider the total cost of ownership, including potential replacement costs for less reliable options.

Reliability and lifespan

Reliability differs between capacitor types. Ceramic capacitors have long lives and stable characteristics. Electrolytic capacitors might have shorter lifetimes when exposed to high temperatures. Film capacitors have excellent reliability and long lives. During selection, consider the device's expected operational life and the environment in which it must survive.

Conclusion

Capacitors are critical in electronic circuitry, and an engineer or hobbyist must know the various types of capacitors that exist. From electrolytic and ceramic capacitors to film capacitors and supercapacitors, each has a multitude of features, making each suitable for a particular application. In discussing their properties, advantages, and limitations, we have received invaluable insight on how to choose the right capacitor for varying circuit needs.

When selecting a capacitor, consider values of capacitance, voltage rating, temperature stability, and frequency response. Picking these variables according to the project's requirements should allow circuit performance and reliability to be optimized. Note that the right capacitor can make a difference in an electronic design; therefore, do visit them better and think before you make a decision.

Related Articles

What Is CBB61 Capacitor - Function and Applications

Capacitor Symbol: What Does It Really Mean?

What is Tantalum Capacitor: Design, Construction and Applications

Capacitor Tester: Types, Applications & Advantages

How to Test a Hard Start Capacitor [Complete Guide]

Polarized vs Non-Polarized Capacitor

Polyester vs Polypropylene Capacitors: Explained

Radial vs Axial Capacitor: Whats the Differences?

Run Capacitor vs Start Capacitor

Tantalum vs Ceramic Capacitor: What's the Differences?

What Causes Capacitors to Fail

What Is CBB61 Capacitor - Function and Applications

What is the Standard Lead Spacing for Capacitors?

Why Do Capacitors Explode?