What is Thermal Relay? All Explained

A relay serves as an electrically actuated switch, facilitating the opening and closing of circuits or the establishment and interruption of electrical connections through reception of electrical signals from external sources. They become indispensable when electrical isolation is imperative in control circuits, or when multiple circuits require control via a singular signal. Various relay types are available in the market, each chosen based on specific application requirements. Thus, the thermal relay represents one such variant, dedicated to ensuring comprehensive safeguarding against single phasing, unbalanced voltages, and overloads. Thermal relays offer an ideal solution for safeguarding motors, ensuring precise tripping in instances of single phasing and overload conditions. This discourse provides an overview of thermal relays, elucidating their operational principles alongside practical applications.

What is a Thermal Relay?

A thermal relay, in essence, is a protective device utilized to offer electromechanical defense to electric motors against overloading and excessive input current. These relays play a crucial role in safeguarding motors from enduring stable electrical damage caused by anomalies such as overvoltages and phase failures. The symbol representing a thermal relay is depicted below.

Structure of Thermal Relay

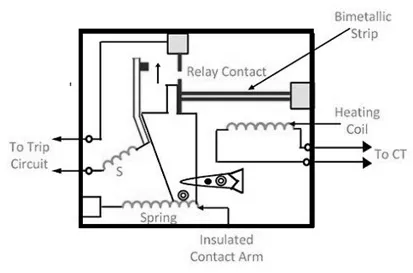

The design of a thermal relay is relatively straightforward. It comprises essential components such as bimetallic strips, heating coils, and a current transformer (CT).

The current transformer (CT) in this relay is responsible for delivering current flow to the heating coils. Consequently, the thermal energy generated by the heating coils heats the bimetallic strips, which are fabricated from materials like steel and nickel alloys. These materials exhibit high resistivity and are resistant to thermal aging.

In the relay described above, an insulated lever arm is directly linked to the trip coil via the bimetallic strips and a spring. The tension of the spring is regulated by a sector-shaped plate.

Under normal operating conditions, the spring remains in its uncompressed state. However, in the event of a fault within the system, the bimetallic spring heats up and flexes, releasing the tension on the spring. This action triggers the relay contacts to trip, energizing the trip circuit and causing the circuit breaker contacts to close. Consequently, the system is safeguarded.

Principle of Operation of Thermal Relay

The underlying principle guiding the operation of a thermal relay revolves around the behavior of a bimetallic strip within the device when subjected to heating from a heating coil. When heated, the bimetallic strip bends, thereby closing normally open (NO) contacts.

During normal operation of a motor, the thermal element within the thermal relay generates insufficient heat to activate the protective function, and its normally closed (NC) contact remains in a closed state. However, in the event of motor overload, the thermal element produces enough heat to trigger the protective function, causing the normally closed (NC) contact to open, thus cutting off power to the electric motor via the control circuit, thereby safeguarding it. Upon resolution of the issue, the relay must be reset before the electric motor can be restarted.

Thermal relays typically offer two reset modes: automatic and manual. The selection between these modes can be easily adjusted by manipulating the reset screw. By default, manufacturers often set the relay to the automatic reset mode. However, the choice between automatic and manual reset modes depends on the specific requirements of the control circuit in use.

Types of Thermal Relays

Thermal relays are categorized into three main types: bimetallic thermal, solid state, and temperature control.

Bimetallic Thermal

A bimetallic thermal relay operates by utilizing a bimetallic strip to mechanically open the contacts. This strip consists of two metal pieces bonded together, each expanding at a different rate when subjected to heat. As the strip heats up, it bends. In this type of relay, the bimetallic strip is linked to the contacts via a spring. When excess heat causes the strip to bend due to overcurrent, the spring is tensioned, pulling the contacts apart and breaking the circuit. Once the strip cools down, it returns to its original shape, restoring the circuit.

Solid State Relay

Solid-state relays operate without any mechanical or moving components. Instead, they gather data regarding thermal overload and the typical temperature of a motor by monitoring its starting and running currents. These relays offer faster response times compared to electromechanical relays and feature adjustable set points and trip times. They are particularly suitable for use in unstable environments where the generation of sparks is undesirable.

Temperature Control Relays

Temperature control relays are specifically designed to directly monitor the temperature of a motor. They achieve this by employing a resistance thermal device (RTD) probe or a thermistor that is embedded in the motor winding. When the temperature of the motor reaches the specified threshold, the resistance of the RTD probe or thermistor increases rapidly. This change in resistance is detected by a threshold circuit, which then opens the contacts of the relay.

Alloy Melting Thermal Relay

An alloy melting thermal relay comprises a heater coil, a eutectic alloy, and a circuit-breaking mechanism. Through the utilization of the heater coil, this relay gauges the motor's temperature by monitoring the current it draws.

Thermal Relay Circuit Diagram & Operation

Displayed below is a thermal relay circuit designed for overload protection, aimed at preventing motor failure. This overload protection circuit consists of essential components including a fuse, contactor, thermal relay, start button, and stop button.

When the thermal relay is employed to safeguard the motor against overload, its thermal element is simply integrated in series with the motor's stator winding. Meanwhile, the normally closed contact of the thermal relay is connected in series with the control circuit of the AC contactor.

In the event of motor overload, the current flow within the winding escalates, causing a corresponding increase in the current flow within the thermal element of the relay. As a result, the temperature of the bimetallic sheet rises, leading to an increase in its level of bending. Subsequently, the normally closed contact is pushed to disconnect, interrupting the AC contactor coil circuit. Consequently, the contactor cuts off the power supply to the electric motor, effectively safeguarding it from harm.

Upon deactivation of the AC power contactor coil and subsequent disconnection of the main contact, the electric motor M comes to a halt, thereby effectively mitigating the risk of motor winding burnout due to overload. Once the overload issue is rectified, pressing the Reset button of the thermal relay and then the Start button (ST) enables the motor to resume operation.

How to Choose a Thermal Relay?

The primary function of a thermal relay is to shield the electric motor from overloading. To ensure adequate and essential overload protection for the electric motor, it is imperative to thoroughly understand the motor's performance characteristics and pair it with an appropriate thermal relay configured to meet the necessary settings. Typically, factors related to the motor, such as starting current, operational environment, working regimen, load characteristics, permissible overload capacity, among others, must be taken into consideration.

The proper selection of the thermal relay is closely linked to the motor's operational requirements. When the thermal relay is employed for long-term motor protection, it is selected based on the motor's rated current. For example, the setting value of the thermal relay may range from 0.95 to 1.05 times the motor's rated current, or alternatively, the median value of the relay's set current may align with the motor's rated current, and then adjusted accordingly.

In scenarios where the relay is tasked with safeguarding a motor subjected to frequent short-term operations, flexibility within a certain range becomes crucial. If there are numerous operations per hour, it is advisable to opt for a thermal relay equipped with a current transformer featuring speed saturation capabilities.

For motors subjected to frequent forward and reverse phases of operation, traditional overload protection relays may not be suitable. Instead, temperature relays or thermistors embedded within the motor windings are employed to provide protection.

These relays are engineered to handle low overloading conditions, typically designed to operate at around 6 to 7 times higher than the full load current.

It's important to note that these relays are not intended for use in short-circuit scenarios. In the event of a short circuit, where the current surge raises the temperature of the bimetallic strip, the relay contacts may close inadvertently. Therefore, this relay is primarily utilized alongside short-circuit relays equipped with time-limited fuses.

The Advantages of thermal relays are manifold

1. Enhanced Precision: Thermal relays boast superior accuracy in their operation.

2. Motor Protection: They effectively safeguard electrical motors from overheating, making them suitable for use in both single and three-phase motors.

3. Easy Installation: These relays are straightforward to install, whether directly onto contractors or onto operation panels using rail adaptors.

4. Convenient Adjustment: Certain relay models feature internal trip class selection buttons for effortless configuration.

5. Reset Options: They come with both automatic and manual reset functions, ensuring ease of operation.

6. Built-in Troubleshooting: Internal test buttons facilitate troubleshooting processes.

7. Wide Current Range: Thermal relays are highly responsive across a broad and adjustable range of currents.

8. Trip-Free Operation: They incorporate trip-free mechanisms for optimal performance.

9. Temperature Compensation: These relays include temperature compensation features, ensuring precise functionality.

10. Versatile Application: Thermal relays can be deployed across various settings with ease.

Despite their numerous advantages, thermal relays also have several Disadvantages:

1. Lack of Short Circuit Protection: Thermal relays typically lack built-in short circuit protection, focusing primarily on electrical protection.

2. Slow Operation: Many thermal relay-based devices exhibit relatively slow operation, which may not be suitable for certain applications requiring rapid response times.

3. Dependency on Additional Devices: They are not designed for direct circuit breaking and often require integration with other electrical protection and switching devices to disconnect live circuits.

4. Limited Effectiveness with Low-Resistance Circuits: Thermal relays are most effective in circuits with higher resistance, and may not perform optimally in low-resistance circuits.

5. Inefficiency in Heavy-Duty Circuits: In heavy-duty circuits, thermal relays may not consistently deliver optimal performance.

6. Vulnerability to Vibrations and Shocks: They are not robust enough to withstand vibrations and electrical shocks, which can compromise their reliability.

7. Limited Switching Frequency: Thermal relays do not support high switching frequencies, often requiring time to cool down after tripping and overheating.

Thermal relays find wide-ranging applications across various industries

1. Motor Overload Protection: Thermal relays are extensively used to protect motors from overload conditions, ensuring their safe and reliable operation.

2. Power Cutoff: These relays serve as protective devices, automatically cutting off power to the motor when it draws excessive current for an extended duration.

3. Overheating Protection: They play a crucial role in safeguarding electrical devices, motors, and transformers from overheating, thereby preventing potential damage.

4. Current-Dependent Protection: Thermal relays are specifically designed for applications where protection against impermissible temperature rises due to phase or overload failure is essential.

5. Electrical Circuit and Device Protection: They serve as protective measures for electrical circuits and devices, offering overload protection to prevent damage and ensure longevity.

6. Low-Output DC Motors and Low-Voltage Induction Motors: Thermal relays are commonly employed in circuits involving low-output DC motors and squirrel cage induction motors operating at low voltage.

7. Motor Starter Circuits: In motor starter circuits, thermal relays play a critical role in preventing motors from drawing excessive current, which could lead to insulation damage and other issues.

8. Ensuring Equipment Longevity: By preventing motor damage and ensuring proper operation, thermal relays contribute to the longevity of equipment and machinery.

The function of a relay is to act as an electrically operated switch that controls the opening and closing of circuits or the making and breaking of electrical connections. Relays receive electrical signals from external sources and use them to control the flow of electricity in a circuit, allowing for the automation of various electrical processes. They are commonly used to isolate and protect control circuits, coordinate the operation of multiple circuits with a single signal, and provide electrical isolation between different parts of a system.