What an Automotive Relay is & How it Works

What an Automotive Relay is?

Automotive relays are crucial parts of contemporary automobiles. They are in charge of using low power signaling to regulate a variety of high power circuits. By facilitating the safe and effective management of vehicle electrical loads, they raise the efficiency and dependability of electrical systems. Relays lengthen the life of switches and other control devices and enhance vehicle performance by enabling complex electrical activities to be carried out with less strain on them.

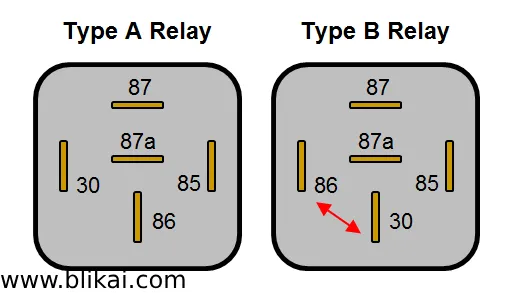

Pinout of Automotive Relays

Depending on the kind and function of the relay, the pin arrangement of automobile relays might change slightly. But generally speaking, an automobile relay has five pins, which are as follows:

- Terminal 30: This is the common power or supply input terminal. It is usually connected to the power source that the relay controls (often +12V from the battery).

- Terminal 85: This is the control circuit ground terminal. It's either linked to the negative side of the control circuit or to ground (typically the vehicle's chassis ground).

- Terminal 86: This is the control circuit power terminal. It receives the control signal (often +12V) that activates the relay coil to close the switch contacts.

- Terminal 87: This is the normally open (NO) contact terminal. To permit current to pass through a control circuit, this terminal is linked to terminal 30 (e.g. to a component such as a fan, light or motor).

- Terminal 87a: This is the normally closed (NC) contact terminal. When the relay is not activated, this terminal is connected to terminal 30. When the relay is activated, this connection is broken.

In many automotive relays, terminals 87 and 87a are often present as a pair (normally open and normally closed), but not all relays have both. Some relays, particularly simpler types, may only have terminal 30, 85, and 86.

Note: It's crucial to consult the specific relay datasheet or diagram for the exact pinout, as variations can exist depending on the manufacturer and the intended use of the relay (e.g., single throw vs. double throw, different current ratings, etc.).

Components of Automotive Relays

Coil: Creates a magnetic field when energized, causing the switch to move.

Armature: A movable iron part that acts as the switching element.

Contacts: Conductive components that open or close the circuit.

Spring: Returns the armature to its original position when the coil is de-energized.

Types of Automotive Relays

Electromechanical Relays (EMR): A traditional relay that opens or closes a circuit using a portable contact medium. It works well and is applicable for the maturity of automotive uses.

Solid-State Relays (SSR): A traditional relay that opens or closes a circuit using a portable contact medium. It works well and is applicable for the maturity of automotive uses. Higher durability and quicker changeover are provided by this. They are typically more costly, though.

Micro Relays: Compact relay with low power requirements. useful in contemporary cars that need more room.

Time Delay Relays: Time delay mechanism integrated right in. permits the activation or deactivation of a circuit after a predetermined amount of time.

How Automotive Relays Work

Basic Working Principle

Automotive relays use low current signals to control high current circuits through the use of electromagnetic principles. It's made up of connections, an architecture, a spring, and an electromagnet. A magnetic field is produced when a tiny current flows through the electromagnetic coil (control circuit). The armature is drawn to this magnetic field. shift The contacts are closed or opened by this movement. circuit that either completes or stops the electric current flow into the load circuit (switching circuit).

Role of the Electromagnet

The primary element that powers the relay is the magnetic. An electromagnet creates a magnetic field when it is powered by a control signal, usually via a switch or electronic control unit (ECU). The shell is drawn inward by this field. overcoming the spring's force to enable the contacts to move. The force exerted on the armature is dependent on the strength of the magnetic field. This has an impact on the relay's operating speed and dependability.

Switching Mechanism

An automobile relay uses the armature's ability to move in response to electromagnetic movement as its switching mechanism. The armature will revert to its rest position when the spring de-energizes the relay (no control signal). The contacts will be able to go back to their original state as a result. (whether it's closed or open) The relay may repeatedly turn the circuit on and off thanks to this technique. Quick and dependable It may therefore be used in a range of automobiles.

Example of Relay Operation in a Vehicle

In a vehicle, relays are used in numerous applications to control high-power devices. For example:

Headlights: When the headlights are turned on, The electromagnet of the relay is activated by a little control signal received from the ECU or headlight switch. The relay contacts are closed by this action. As a result, more electricity may go straight from the battery to the headlights. to provide these sections light.

Fuel Pump: The fuel pump that transfers fuel from the tank to the machine is managed by the fuel pump relay. The ignition switch activates a signal that's entered by either the ECU or a separate fuel pump relay. The relay receives power from this. To enable the gasoline pump to be powered by battery electricity, they seal the connectors. In order to start the engine, pressure is then built up in the fuel system.

In both cases, high power circuits can be effectively and safely managed by using low power control signals thanks to relays. They guarantee the dependable operation of vital components while safeguarding the electrical system of the car.

Applications of Automotive Relays

Common Applications:

Lighting Systems: Controlling headlights, fog lights, and indicator lights.

Fuel Systems: Operating fuel pumps and injectors.

Heating and Cooling Systems: Managing HVAC systems, including fans and compressors.

Security Systems: Activating alarms and immobilizers.

Engine Management: Controlling various sensors and actuators involved in engine performance.

Advanced Applications:

ECU (Engine Control Unit): Fuel injection is one of the many functions that relays regulate and are managed by the ECU. Fan operation for engine cooling and idle speed management.

Sensor Integration: Makes it easier to integrate sensors, including temperature sensors and relays. location and pressure sensors suitable with the control systems of cars permits communication between these sensors and the car's electrical system. achieving optimal efficacy and efficiency.

Advantages

Efficient Power Management: Relays facilitate the control of high-power devices via small switches. Lessen the strain on the control system of the car. and boost overall productivity.

Protection: Through separating the low current control part from the high current circuit. The relay guards against high current damage to delicate electrical components.

Durability: Relays are made to withstand large currents and work under challenging automotive conditions. It prolongs the lifespan and dependability of the electrical system in the car.

Safety: Relays contribute to the secure operation of vital systems like ignition and illumination. and gasoline pump play a significant role in safety measures like airbags and ABS.

Troubleshooting and Maintenance of Automotive Relays

Common Relay Problems

Corrosion: Relay connectors and contacts are susceptible to corrosion over time. Poor electrical conductivity and unstable operation are the results of this.

Wear and Tear: Mechanical components like springs and armatures. Because they are replaced frequently, they could degrade. This has an impact on the relay's efficiency.

How to Test a Relay

Visual Inspection: Look for corrosion indications. physical harm to the contacts, connectors, and relay housing, or overheating (discoloration).

Continuity Test: When the relay is turned on, use a multimeter to make sure there is continuity—low resistance—between the relay terminals. Certain pairs of terminals should have continuity between them, depending on the type of relay. (Usually closed or open normally).

Voltage Test: Following the application of the control signal, measure the voltage across the relay coil terminals. A relay that is operating correctly should display the necessary voltage drop across its coils.

Operational Test: Give the relay coil a control signal, typically 12 volts DC. and when you open or close the contacts, pay attention for the clicking sound. Check the relay's switching contacts with a voltmeter to see if there is continuity or a break.

Tips for Maintaining Relay Performance

Proper Wiring: To guarantee safe and effective relay functioning, use gauge wire and connectors.

Regular Inspection: Check for wear or deterioration, such as corrosion or contact holes, on a regular basis.

Replacement: To avoid damaging other electrical equipment, replace faulty relays as away.

Selecting the Right Relay

Current and Voltage Ratings: Corroborate that the relay can sustain the operation's requirements for voltage and current.

Contact Configuration: Depending on the circuit design, choose between Single Pole Single Throw (SPST), Single Pole Double Throw (SPDT), and Double Pole Double Throw (DPDT).

Physical Size: Consider the available space within the vehicle.

Environmental Resistance: For uses in challenging environments. Choose a relay that has the right temperature rating and sealing.

Conclusion

Automotive relays are essential for controlling the intricate electrical systems set up in contemporary motorcars. It's possible to choose and maintain the ideal relay for any particular demand by being apprehensive of its type, function, and operation. It contributes to the electrical system of the car operating dependably and effectively.

Related Articles

The Automotive PCB Market Seizes Fresh Opportunities

What is Signal Relays? Everything You Need to Know

5V Relay Pinout: Working & Its Applications