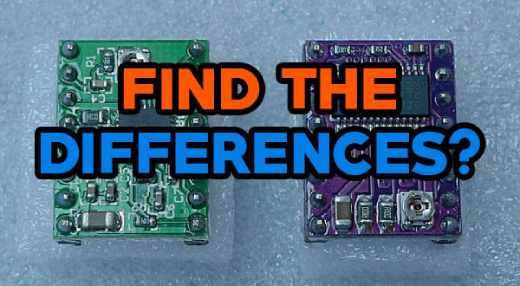

A4988 VS DRV8825: What's the Main Differences? (Guide)

DRV8825 and A4988 are two popular stepper motor drivers often compared when selecting one for your project. A wide range of applications require precise motor control, including 3D printers, CNC machines, and other devices. Apart from microstepping capability and compatibility with common steppers, each stepper motor offers distinct performance, features, and prices. In order to choose the right driver, you need to have a clear understanding of these differences, whether you're seeking a high current capacity, finer microstepping resolution, or an affordable option. Choosing the right stepper motor driver for your next project can be a daunting task, but that is what this guide aims to help you do.

What is A4988?

There are eight, sixteenth, and quarter steps modes for bipolar stepper motors. There is a great deal of use for the A4988 stepper motor driver in industry. It supports smooth motion and precision control, making it ideal for applications such as 3D printers, CNC machines, and robotics. Featuring adjustable current limiting, over-temperature shutdown, and crossover-current protection, the A4988 can handle up to 2A per coil with adequate cooling. As a result of its compact size and its ability to integrate easily with popular microcontrollers and development boards like Arduino, it is popular with both hobbyists and professionals.

What is DRV8825?

This high-performance stepper motor driver features advanced features and capabilities that are utilized for controlling bipolar stepper motors. Compared to standard drivers such as the A4988, it provides finer control and smoother motion. The DRV8825 is the ideal choice for robotics, 3D printers, CNC machines, and CNC machines that require high torque and precision. A number of built-in protection features ensure reliable operation under challenging operating conditions, including over-current and over-temperature protection. The DRV8825 is a favorite among enthusiasts and professionals because it is compatible with a wide range of microcontrollers and is easy to integrate.

A4988 VS DRV8825: Features

A4988

Microstepping Capability: The motion control system supports full steps, half steps, quarter steps, eighth steps, and sixteenth steps.

Current Handling: Suitable for driving bipolar stepper motors in various applications, capable of handling up to 2A per coil with adequate cooling.

Adjustable Current Limiting: Optimizes motor performance and efficiency by adjusting the maximum current output.

Over-temperature Shutdown: Drivers are equipped with thermal shutdown circuitry to prevent overheating and ensure long-term performance.

Crossover-current Protection: Enhances safety by preventing damage caused by excessive current during motor operation.

Compact Design: Easy integration with microcontrollers and development boards like Arduino thanks to compact package size and straightforward pin configuration.

Cost-Effectiveness: A popular choice for hobbyists and low-cost applications because it is generally more affordable than higher-end stepper motor drivers.

DRV8825

Higher Microstepping Resolution: Microstepping resolutions up to 1/32 are supported, providing smoother motion control and more precise positioning.

Higher Current Capacity: A stepper motor requiring higher torque and power can be driven with this coil capable of delivering up to 2.5A per coil with appropriate heat sinking.

Sophisticated Thermal Management: Thermal management capabilities which allow higher currents to be delivered without overheating the driver.

Over-current and Over-temperature Protection: Safety features such as over-current and over-temperature protection are built into the driver to ensure safe operation.

Back EMF Protection: Stepper motor drivers and control electronics are protected against voltage spikes generated by back electro-motive force (EMF) diodes.

Compatibility and Integration: Flexibility in the design and implementation of systems thanks to the compatibility with a wide range of microcontrollers and development platforms.

Performance and Precision: Enhanced current handling capability and finer microstepping result in smoother operation and greater precision. CNC machining, robotics, 3D printing, and robotics applications require this technology.

Applications: A4988 VS DRV8825

A4988

3D Printers: For extrusion, bed leveling, and axis movement, stepper motors are controlled by A4988 drivers in 3D printers. Suitable for precision applications due to their moderate current handling and reliable microstepping ability.

CNC Machines: Stepper motors move cutting tools or workpieces with high accuracy with the assistance of A4988 drivers in CNC (Computer Numerical Control) machines. Precision positioning and moderate torque make them ideal for applications requiring moderate torque.

Robotics: Joints and other motorized mechanisms can be controlled by A4988 drivers in robotics. Robotic arms, grippers, and other automated systems rely on them for torque and smooth motion control.

Automated Systems: Due to their compact size, ease of integration, and cost-effectiveness, A4988 drivers are used in a variety of automated systems, including camera sliders, telescopes, and small-scale automation projects.

Consumer Electronics: Robots, camera gimbals, and motorized toys are examples of consumer electronics products incorporating A4988 controllers for driving stepper motors.

DRV8825

High-Precision 3D Printers: Drivers for 3D printers requiring finer details and smoother motion are recommended for use with DRV8825. In addition to the higher microstepping resolution (up to 1/32 step), the smoother surface finish is achieved because of the higher microstepping resolution.

High-Torque CNC Machines: The DRV8825 can deliver up to 2.5A per coil, making it ideal for CNC machines handling heavier workpieces or requiring more torque. With this higher current capacity, this device can operate reliably under load without compromising precision.

Medical and Laboratory Equipment: Precision microscopes, automated pipetting systems, and medical imaging devices all use DRV8825 drivers for precision control over stepper motor movements.

Industrial Automation: Drivers for DRV8825 are compatible with conveyor systems, robotic arms, and automated assembly lines, which are suited for demanding environments and differing loads.

Large Format Printers: It is used to provide accuracy and consistency of print quality across wide print areas on large format printers, such as posters, banners, and architectural drawings.

Motion Control Systems: DRV8825's advanced features and durability make it ideal for high-precision motion control systems, including robot surgery systems and automated inspection machines.

A4988 VS DRV8825: Differences

Microstepping Resolution

A4988: Compared to full-step operation, microstepping offers smoother motion with fewer intermediate steps to provide finer control.

DRV8825: High precision and smoother movement are enabled by a 1/32 microstepping resolution, particularly beneficial in precision-oriented applications.

Current Capacity

A4988: Suitable for applications requiring moderate torque, it can handle up to 2A per coil with adequate cooling.

DRV8825: Achieves higher torque output and robust performance in applications requiring more power with a maximum current delivery of two amps per coil when properly heat sunk.

Heat Dissipation and Thermal Management

A4988: If it operates near its current limit, it needs effective cooling mechanisms to prevent overheating.

DRV8825: It provides greater reliability in demanding environments thanks to its enhanced thermal management capabilities.

Protection Features

A4988: The driver and connected components are safeguarded against damage by basic protections like over-temperature shutdown.

DRV8825: Enhances operational safety and longevity with features such as overcurrent and thermal shutdown protection.

Cost and Affordability

A4988: For lower-budget projects with moderate performance requirements, it's a popular choice over the DRV8825.

DRV8825: Because of its greater precision, torque, and reliability, it is priced higher because of its superior performance capabilities.

Wrapping Up

It all depends on the specific requirements of your project whether you choose the A4988 or the DRV8825 stepper motor drivers. It offers moderate current handling capabilities and cost-effective microstepping capabilities for applications with modest precision and torque demands. A hobbyist's project, 3D printer, or small CNC machine can benefit from it. Its higher microstepping resolution, increased current capacity, and advanced thermal management, however, make it more powerful. In applications such as high-precision 3D printers, industrial automation, and medical equipment, it is well-suited for motion control, torque, and reliability. Make the best choice for your stepper motor control needs in consideration of precision, torque, and thermal management requirements.

Related Articles

How do A4988 and DRV8825 vary from one another?

SN6505BDBVR Transformer Driver: Features, Application and Datasheet

What is the DRV8825 Stepper Motor Driver? A Detailed Description