What Are Parts of Motors? Here's What You Should Know

Understanding the Basics of Motors

Motors are devices used to transform forms of energy into motion and force in the form of mechanical energy. They're an integral element in numerous machines and systems, ranging from small consumer appliances to large-scale ministries. Most motors convert energy to produce rotary or linear motion, thus enabling power transmission.

How motors convert energy

Motors follow the principle of transformation of energy. They usually take in one form of energy input, like electrical energy or chemical energy, and convert it into mechanical energy. The conversion takes place as a result of the interaction of components inside the motor. For instance, an electrical motor works by converting electrical energy into building magnetic fields that interact with each other to generate rotational motion.

Common types of motors

Since each type of motor serves a specific application, there are many kinds of motors:

- Electric motor: These will relate to DC, AC, and brushless DC motors, which are extensively used in colorful diligence and consumer products.

- Internal combustion engines: Convert chemical energy released from energy into mechanical energy through combustion. They're basically used in all vehicles.

- Hydraulic motors: Induce mechanical power by using pressurized fluids; heavy ministries and manufacturers frequently use these types of motors.

- Pneumatic motors: These are powered by compressed air and are generally used in tools and robotization systems.

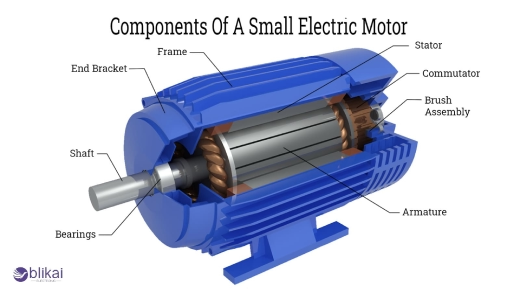

Essential Components of Electric Motors

A. Stator: The stationary part

The stator is the non-rotating part of an electric motor that provides a frame for such a motor. It is a cylindrical frame whose interior fits a number of electromagnets or permanent magnets arranged in a circle. The magnetic field created from this will be static, and in conjunction with the rotor, its interactions will produce motion.

B. Rotor: The rotating part

The rotor is the heart of the electric motor and was built to turn within the stator. Generally, the rotor consists of a shaft upon which conducting coils and/ or endless magnets are placed. As current passes through the windings of a rotor, it produces a glamorous field that interacts with the stator field to beget gyration.

C. Commutator: Reversing current flow

Installed in the DC motor, the commutator is a non-whetted arrangement element that reverses the current flowing in the rotor windings. This reversal is done at the proper points to ensure continuous motion. The commutator comprises a set of copper segments that carry current through the motor shaft in conjunction with the brushes.

D. Brushes: Conducting electricity

Brushes are conduits through which electricity flows between the power supply and the commutator in a DC motor. They are typically made of carbon or graphite and are spring-loaded. They maintain contact with the rotating commutator to flow electricity to the rotor winding.

E. Windings: Creating magnetic fields

Windings are insulated, covered wire artfully hooked around the segments or sections of the stator and the rotor. As flowing current passes through the windings, a magnetic field is created. The interaction of stator and rotor magnetic fields supplies the turning moment-to-torque powering the motor. The configuration of these windings greatly influences motor performance data.

Key Parts of Internal Combustion Motors

Engine block: The primary structure

The engine block, also known as the cylinder block, is the heart of an internal combustion motor. This sturdy element contains the cylinders and supports the whole engine. To repel the extreme temperatures and pressure generated by combustion, an engine block is generally cast from iron or aluminum blends.

Pistons: Driving force generators

A piston is a spherical element that can freely slide up and down the engine's cylinder. When the spark plug ignites the energy-air admixture, an important explosion forces the pistons over, converting heat energy into mechanical energy; this provides the factual driving force for the internal combustion motors.

Crankshaft: Converting motion

The main crankshaft receives the thrusts from the pistons, intensified by connecting rods that transform the pistons' linear motion into rotational energy. It is an integral shaft transferring power through the trans to the wheels. It will also further counterbalance the engine and decrease engine vibration with respect to the counterweights attached to it.

Camshaft: Controlling valves

A camshaft is the shaft that allows valves to open and close at the correct time on an engine. Lobes push against valve lifters and lift the valves open as the camshaft rotates. It alternates the input of the energy-air admixture and the expatriation of the exhaust feasts.

Fuel injection system: Delivering fuel

ultramodern internal combustion motors calculate on fuel injection systems to deliver the right quantum of fuel at the correct time. This system replaces aged carburetors, offering more precise fuel metering and improved effectiveness. It consists of fuel injectors, a fuel pump, and an electronic control unit that optimizes fuel delivery grounded on colorful engine parameters.

Crucial Motor Support Systems

Cooling system: Preventing overheating

The primary function of a motor's cooling system is to allow it to perform well and last long. Due to the heavy heat generated, it is necessary to cool a motor efficiently. In most electric motors, air cooling is preferred. In air-cooled systems, air is blown over the motor factors through addict blades placed at different strategic positions. In discrepancy, liquid cooling systems are generally employed for internal combustion engines, in which the coolant absorbs the heat and helps in transferring it out via the radiator.

Lubrication system: Reducing friction

The lubrication system is a significant factor in minimizing friction between moving factors, therefore minimizing wear and tear and gash and dragging the motor life. Slicking systems are frequently concentrated on comportments in electric motors, where special greases or oil are applied in the fittings to allow proper gyration. Internal combustion engines have further complex lubrication requirements, with oil pumps circulating lubricant throughout the engine to fleece the pistons, crankshafts, and other moving factors.

Electrical system: Powering components

The electrical system is indispensable for both electric and internal combustion motors. For electric motors, the electrical circuit is the source supply system, which provides control of the energy that runs the motor. This comprises controllers, inverters, and wiring. In internal combustion engines, the electrical system allows for ignition, fuel injection, and various auxiliary systems. Key components include the battery, alternator, and starter motor, all working together to ensure reliable operation and performance.

Enhancing Motor Performance

Bearings: Reducing friction in rotation

Bearings are one of the most critical ways in which the friction between adjacent moving parts is minimized, thus boosting motor performance. They give an exact design that allows for smooth gyration of shafts or other rotating factors, significantly reducing the wear and tear- and- gash and power losses. Quality comportments, similar to ball comportments or comber comportments, can dramatically ameliorate a motor's operating effectiveness and service life.

Gears: Adjusting speed and torque

The gear is essential for optimizing motor output by altering respective speed and torque ratios. Different gear configurations can also fine-tune these motors to meet specific application requirements. Examples include reducing the speed while using a reduction gear to increase torque so that it becomes applicable for applications requiring higher force at low speeds.

Sensors: Monitoring motor conditions

Modern sensor systems are exceedingly crucial for various motor operations, providing real-time data on any selected operational parameters. Temperature sensors, vibration sensors, and current sensors are also sensitive to monitoring possible future problems that may affect running operations, thus optimizing performance and avoiding unnecessary breakdowns.

Control units: Optimizing motor function

Control units act as the motor system brains that process data obtained from sensors and telegraph to the motors to function as required. These sophisticated devices can control speed, power consumption, and safety parameters. By utilizing advanced algorithms and feedback systems, control units can significantly enhance motor efficiency and responsiveness, leading to improved overall performance.

Maintenance Tips for Motor Parts

Regular inspection routines

First, visually check the motor for any signs of wear and tear, damage, or loose connections. Pay special attention to comportments, belts, and pulleys, as these factors cause a lot of stress. In addition to bearing replacement and checking the oil level in the motor, be sure to listen for unexpected sounds when the motor is running. Make sure belts and chains are correctly aligned and tensioned. Temperature monitoring is a must to ascertain that the motor temperature is normal; furthermore, regular tests on the insulation resistance of the motor will keep electrical failures at bay.

Cleaning and lubrication best practices

Cleaning the motor is an essential part of ensuring that it works efficiently. Dust and dirt can be easily removed by using compressed air on the outside surface and around the ventilation openings of the motor. For stubborn grime, it is better to use a soft brush or cloth moistened with some mild solvent. Be careful that the cleaner does not seep into the motor. Lubrication should be carried out as recommended by the manufacturer in terms of both the kind of lubricant and the frequency of service. Use lubricants neither too sparingly nor too free-handedly since inordinate greasing may pose a serious problem, similar to inadequate greasing. Pay particular attention to bearing surfaces, which require regular lubrication to operate correctly.

Related Articles

Brushed vs Brushless Motors: What's the Difference? (Guide)

What is a Brushless Motor: Types, and Functions (Guide)

Applications of Induction Motor: And its Types

Electric Motors Applications and Features: Fully Explained

What L298 Motor Driver IC is :Pinout and & Applications

Induction Motors: Working Principle and Types (Guide)

What is the DRV8825 Stepper Motor Driver? A Detailed Description

Different Types of Electric Motors All Explained

What is an Induction Motor :All You Need to Know

How Does a Single Phase Motor Work?

What L298 Motor Driver IC can do and How it Works

Do ECM Motors Have Capacitors?

Do Capacitors Get Hot? [All You Know]

How to Test ECU with Multimeter: Complete Guide