Rheostat vs Potentiometer: Key Differences & Applications Explained

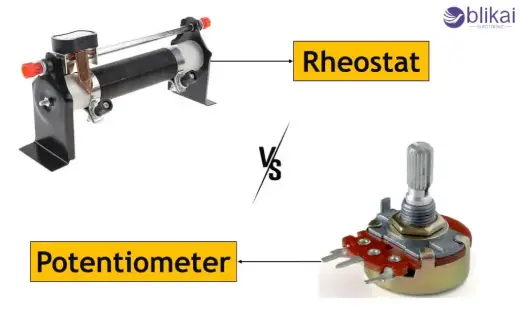

A rheostat or potentiometer can be two common examples of a passive component in the area of electronics and electrical engineering such as resistance control. Although they are considerably similar and have the capacity to change resistance, their working principles, circuit connections together with real-life applications vary significantly.

In this paper, we are going to explain why rheostat and a potentiometer are the two critical differences that matter and how they can be used, where they are usually deployed, as well as how one can find the most suitable component in a specific situation.

What Are Rheostats and Potentiometers?

Both a rheostat and a potentiometer are variable resistors at heart. They have an anticipated use and implementation of differing aforementioned purposes, although they operate in similar manners permitting the user to adjust the resistance in an electrical circuit by manual means:

- Rheostat is mainly applied to control current flow. It normally works in a series with a load, and has two terminals one fixed and the other movable (wiper).

- To attain variable voltage levels a potentiometer is applied and normally connected as a voltage divider utility terminals: two to any terminal of a resistive track and the third to a moveable wiper.

How a Rheostat Works

A rheostat is actually an electrical current device that varies the resistance through which it passes. By simply moving the wiper along the resistive element the length of a current path varies, and hence the change in resistance.

Key Technical Features:

Two-terminal operation

Connected in series with the load

Variable current control

Often constructed with wire-wound resistive elements to handle higher power

The main aim of a rheostat is to decrease or to flow the current passing through a circuit without leading a break in the same.

How a Potentiometer Works

Potentiometer is a variable voltage divider. Via the resistive track, a point is chosen between one end of the tracks (the high voltage end) and the other end (the low voltage end) as the wiper travels along it. The wiper output voltage depends on the position of the wiper.

Key Technical Features:

Three-terminal operation

Connected as a voltage divider

Variable output voltage

Used extensively in signal-level adjustments and user interfaces

Most typically potentiometers are used to precisely adjust voltages in low-current applications, which is good in applications where there are analog signals and user adjustment controls.

Key Differences: Rheostat vs Potentiometer

In order to distinguish well between the differences, the comparison table below highlights the main points of their differences:

|

Feature |

Rheostat |

Potentiometer |

|

Number of Terminals |

2 |

3 |

|

Primary Use |

Controlling current |

Adjusting voltage |

|

Circuit Connection |

Series |

Voltage divider (or variable resistor) |

|

Wiring Simplicity |

Simple (fewer connections) |

Slightly complex (requires 3 wires) |

|

Power Handling |

High |

Low to moderate |

|

Resistance Range |

Typically lower resistance (e.g., 0–1kΩ) |

Wider range available (e.g., 1kΩ–1MΩ) |

|

Adjustment Type |

Coarse |

Fine/precise |

|

Applications Multi-Gang |

Heaters, motors, lighting |

Audio controls, sensors, analog tuning |

|

Durability |

Mechanically rugged for industrial environments |

Suitable for low-power control interfaces |

|

Typical Form Factor |

Rotary wire-wound; sometimes linear slide |

Rotary, slide, thumbwheel, or digital (IC) formats |

Performance Characteristics

In the sense of choosing a variable resistor, both reliability and functionality are essential in knowing the performance metrics:

1. Linearity

Potentiometers may be linear and log (audio taper). Rheostats have a tendency to have a linear characteristic of resistance.

2. Wiper Contact Quality

The contact between the wiper and the resistive track may be subject to degradation with time either by introducing electrical noise or producing unpredictable operation.

3. Thermal Stability

Rheostats are constructed in a fashion that they can endure a larger power dissipation and their construction is wire-wound rather than the carbon-film potentiometers that complicate heat dissipation.

4. Wear and Lifespan

Potentiometers to account for multiple adjustments by the user (e.g. volume adjustments) can degrade more quickly. Better life and reliability is provided by multi-turn types and sealed potentiometers.

Applications of Rheostats and Potentiometers

Rheostat Applications

Rheostats are very useful in industrial and electrical applications including:

- Motor Speed Control: Adjusting resistance in the armature circuit to vary motor speed.

- Lighting Systems: Dimming or increasing brightness in incandescent lamps.

- Heaters: Regulating heating elements in laboratory or industrial heating systems.

- Test Equipment: Used in variable load testing and current-limiting circuits.

- Generator Load Banks: For simulating electrical loads during generator testing.

Example: A lab technician uses a 100W wire-wound rheostat to test the maximum safe load current for a new DC motor.

Potentiometer Applications

Potentiometers are common in low-voltage, low-current electronics where the goal is signal control or the control of user-specified variables.

- Audio Equipment: Used as volume knobs, tone controls, and balance faders.

- Sensor Calibration: Fine-tuning analog sensor circuits like thermistors, LDRs, or pressure sensors.

- User Interfaces: Found in oscilloscopes, laboratory instruments, and control panels.

- Position Feedback: Rotary and linear position detection in robotics and automation systems.

- RC Circuits and Timing Adjustment: In oscillators, delays, and tuning circuits.

Example: Adjusting the volume on a guitar amplifier acts on a logarithmic potentiometer.

Choosing the Right Component

To make a choice between rheostat or potentiometer, ask yourself the following major questions:

What do you need to control—current or voltage?

Use a rheostat for current control in series.

Use a potentiometer for voltage division or analog tuning.

How much power will be dissipated?

Rheostats are designed for high-power handling.

Potentiometers are designed for low-signal applications.

Do you need fine control or rough adjustment?

For coarse current limiting, go with a rheostat.

For precision tuning, a potentiometer is the better choice.

Do you need remote or digital control?

Look to digital potentiometers (digipots) for microcontroller based system applications.

These deliver more accuracy, reduced wear and no moving mechanism.

Installation Tips & Wiring Guidelines

Proper installation can enhance component lifespan and circuit reliability:

- Avoid overloading: Always check the rated wattage and maximum current.

- Use proper terminal orientation: Especially important for voltage dividers.

- Use heat sinks: For high-power rheostats to dissipate generated heat.

- Secure mechanical mounting: Prevents vibration and contact degradation.

- Shield signal lines: Potentiometers in analog paths may pick up EMI; shielding can reduce this.

Common Mistakes to Avoid

Understanding common errors can save time, cost, and potential circuit damage:

- Using a potentiometer in place of a rheostat in a high-power load – likely to overheat and fail.

- Ignoring terminal configuration – miswiring can result in unexpected behavior or incorrect voltage readings.

- Expecting high precision from a rheostat – rheostats are generally for bulk current control, not tuning.

- Installing in dirty or humid environments without protection – leads to corrosion and failure.

Advanced Variants and Modern Alternatives

Along with technological progress, the rheostats and potentiometers have nowadays been modernized:

1. Digital Potentiometers (Digipots)

Controlled via SPI/I2C

No moving parts = higher reliability

Can be adjusted by microcontrollers or software

2. Multi-Turn Potentiometers

Offer extreme precision over wide resistance ranges

Common in calibration and instrumentation

3. Motorized Potentiometers

Used in audio mixers or professional equipment

Automatically adjust positions via servo control

4. Precision Wire-Wound Rheostats

Designed for laboratory environments

Provide accurate and durable resistance control for test benches

Conclusion

The terms rheostat and potentiometer are used to describe fundamentally different yet closely related components in electrical and electronic design which cannot be used interchangeably. When selecting a particular component you need to know what the application is, maybe you are adjusting current in a high-power circuit or adjusting voltage in a sensitive analog circuit.

- Use a rheostat when you need rugged, high-power control of current.

- Use a potentiometer when you need precise, low-power adjustment of voltage.

Some images are sourced online. Please contact us for removal if any copyright concerns arise.

How Does a Potentiometer Work? Function & Circuit Explained

AC Capacitor Keeps Blowing: What to Do Next?

Is a Fuse a Resistor? [Everything Explained]

Multimeter Not Reading Current [How to Fix]

Temperature Coefficient of Resistance

ESP32 vs ESP8266: Which One Should You Choose?

Regulated vs Unregulated Power Supply: What's the difference?

Understanding Coupled Inductors: Operations and Practical Applications

How to Test a Varistor?(Complete Guide)

Arduino vs. Raspberry Pi: An In-Depth Contrast