Thyristor Controlled Reactor: Working Principle and Applications

Have you ever wondered how power systems maintain stability and control voltage fluctuations?

Understanding Thyristor Controlled Reactors (TCRs)

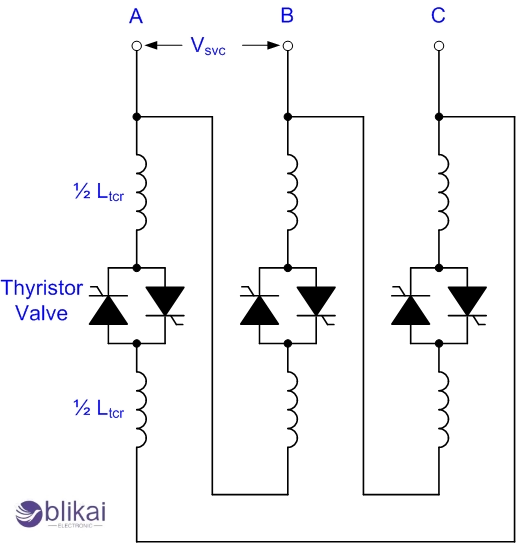

Thyristor Controlled Reactors (TCRs) are specialized power electronic gadgets employed in electrical systems to supply active power compensation. TCR unit is a combination of a fixed reactor in conjunction with a thyristor pair connected in antiparallel. In this configuration, a specific current going through the reactor can be controlled, and this, in turn, modifies the reactance.

How TCRs regulate reactive power

TCRs regulate reactive power by controlling the current through the reactor. This is achieved by adjusting the firing angle of the thyristors. When the thyristors are fully on, maximum current flows through the reactor, providing minimum reactance. As the firing angle increases, the current decreases, effectively expanding the reactance.

Working Principle of Thyristor-Controlled Reactors

Thyristor operation in TCRs

The thyristors used in the thyristor-controlled reactors (TCRs) are electronic switches that control the current flow through the reactor. A gate signal activates these semiconductor units, enabling them to transmit electricity in a controlled form. By turning on the thyristor, current can flow through the reactor thus changing the reactance of the device.

Control of current flow through the reactor

The firing angle of the thyristors controls the flow that passes through the reactor. If we delay the gate control point, the thyristors will switch on at different positions of the AC voltage cycle. This ability to finely control the bridge enables the smooth tuning of the reactor's effective inductance, hence modulating reactive power in the system.

Relationship between firing angle and reactive power

Directly proportional to the firing angle of the thyristors, the quantity of reactive power drawn in by the TCR is impacted. While the firing angle increases, the conduction cycle of the thyristors gets relatively smaller, which means less current is passing through the reactor. This results in a decrease in the proportion of reactive power absorption. On the other hand, a lesser firing angle boosts the conduction period, which further enables larger amounts of current to pass through the TCR, thereby increasing the reactive power absorption.

Response time and precision of TCRs

With TCR, the accuracy and response time in the control of reactive power is unmatched. The electronic design of the thyristors permits quick switching, which helps TCR systems respond to alterations in the system within a couple of milliseconds. This reasonable response speed, along with the modification of the trigger angle, allows very accurate and dynamic control of power reactive systems.

Key Components of Thyristor Controlled Reactors System

Thyristors: The heart of the TCR

Thyristors are the building blocks of a TCR system. They work as controllable switches that turn the current through the reactor on and off. These types of semiconductors have adjustable control over the conduction angle, which makes it possible to absorb reactive power with great accuracy. Usually, thyristors are deployed in antiparallel pairs to bidirectionally conduct both the positive and negative half cycles of the AC waveform.

Reactors: Managing reactive power

The primary consumer of the reactive power is the inductor, which is usually the air core. Inductive reactance is the capacity that the reactor has to absorb energy which increases with the conduction angle of the thyristor. The reactor has to be designed so that voltage rating, current capacity, and harmonic performance will best serve system operation.

Control system: Ensuring optimal performance

A TCR’s efficient functioning hinges on an intricate control system. It controls the grid state, analyzes data from multiple sensors, and calculates the required firing angles of the thyristors. To manage system voltage and reactive power demand quickly while keeping the grid stable, the control system typically utilizes sophisticated algorithms that automatically adjust appropriate voltage level settings.

Cooling systems: Maintaining operational efficiency

Achieving effective cooling is important for TCR components, especially thyristors and reactors since they produce a lot of heat. Based on the size and application of the TCR, cooling systems may use forced-air or liquid cooling methods.

Applications of Thyristor-Controlled Reactors in Power Systems

A. Voltage regulation in transmission networks

Thyristor Controlled Reactors (TCRs) are essential for the regulation of stable voltages in transmission systems. While TCRs adjust reactive power, they also try to ensure balance to the voltage dip or rise due to load change or other disturbances in the network.

B. Power factor correction in industrial settings

In industrial sectors, TCRs are very helpful in improving the power factor. They optimize the level of reactive power provided, which enables active power to be used proportionally to reactive power.

C. Flicker mitigation in arc furnace operations

Due to their unpredictable and non-linear loads, arc furnaces are infamous for causing voltage flicker and are commonly used in steel production. TCRs solve the problem by swiftly compensating the reactive power to offset the fluctuations from the arc furnaces.

D. Stability enhancement in renewable energy integration

Due to their unpredictable and non-linear loads, arc furnaces are infamous for causing voltage flicker and are commonly used in steel production. TCRs solve the problem by swiftly compensating the reactive power to offset the fluctuations from the arc furnaces.

E. HVDC systems: Improving power quality

The HVDC system relies heavily on TCRs to enhance its power quality performance. The converter stations use TCRs for harmonic control purposes while performing voltage regulation and reactive power supply.

Advantages of Thyristor-Controlled Reactors

Rapid response to load changes

The speed of reaction represents one of the controlled Reactors (TCRs) primary strengths during power demand fluctuations. The rapid response mechanism in Thyristor Controlled Reactors differs from conventional reactive elements since these devices achieve quick reactive power adjustments through milliseconds and react to sudden load variations. The fast response capabilities of these devices provide essential stability support when grid demand fluctuates unpredictably while renewable energy intermittency occurs.

Improved power factor and voltage stability

Dynamic control equipment known as TCRs functions to increase power factor correction and stabilize voltage levels. The control system uses TCRs to adjust reactive power dynamically, which enables voltage maintenance during changing load conditions. Technically efficient power transmission occurs along with distribution through improved power factor, which decreases stress on electrical machinery, thus resulting in extended equipment lifetime.

Reduced transmission losses and enhanced grid efficiency

The application of TCRs delivers dual benefits by reducing power transmission losses while enhancing the entire electrical grid efficiency. The optimized reactive power flow operation of TCRs enables them to lower the required current volume for transferring specific amounts of real power. Lower I²R transmission losses occur as a result of reduced current flow, which leads to better energy efficiency and cost reduction, specifically for power utility companies and their customers.

Comparisons with fixed reactors and mechanically switched capacitors

The performance quality of TCRs surpasses that of fixed reactors and mechanically switched capacitors in every aspect. Variable power compensation through TCRs offers system operators precise voltage control services that fixed reactors cannot provide. TCRs present improved reactive power adjustment through continuous operation since they remove the mechanical limitations found in mechanically switched capacitors. YC-damped controllers lead to fewer maintenance demands and prolonged equipment duration, which makes TCR systems a financially sound and dependable solution for modern utility reactive power compensation operations.

Challenges and Considerations in TCR Implementation

Harmonics generation and mitigation

Switching operations of thyristors produce harmonic currents that result in equipment stress together with power quality problems. Engineers need to introduce strong harmonic mitigation approaches as a solution. Hybrid filters, along with passive elements and active components, serve as mitigation strategies.

Maintenance requirements

Maintenance operations on TCRs need to be regular due to their position as complex electronic systems in order to preserve both operational efficiency and system lifetime. Routine checks should focus on thyristor components alongside cooling systems and control systems in the devices. Most troubleshooting and repair operations demand specialized expertise because of which operational costs become higher.

Integration with existing power systems

Technical installation of TCRs in regular power systems involves numerous design obstacles. Engineers need to evaluate thoroughly how TCR devices affect system stability coupled with protection components and broader power grid dynamics. The fully integrated operation between TCR devices and the existing SCADA framework depends on their capability to share the same communication protocols.

Conclusion

Power systems today heavily depend on Thyristor Controlled Reactors (TCRs) since these devices deliver dynamic reactive power compensation combined with advanced voltage control functionality. Engineers who learn the basic working mechanism and fundamental elements and applications of TCRs can fully maximize their power system stability and performance potential.

Related Articles

Thyristor vs Transistor: What are the Differences?

2N1595 Thyristor: Features and Its Applications

Plug Flow Reactor (PFR): Principle,Features,and Applications

Plug Flow Reactor: Working, Characteristics & Its Applications

STM32F407IGT6 Microcontroller: Features, Applications and Datasheet

STM32F030F4P6 Microcontroller: Overview, Applications, and Datasheet

MC9S12XHZ256CAG Microcontroller: Overview, Specifications and Applications

What a PID Controller is Explained

AT89S52 Microcontroller:Applications, Features and Datasheet

2P4M Silicon Controlled Rectifier (SCR): Pinout and Application

8051 Microcontroller:Features,Applications and Types

Getting Started with Arduino Leonardo Microcontroller

What is ARM7 Based (LPC2148) Microcontroller ?All Explained

ARM Microcontroller : Features,Applications and Function