Wirewound Resistor: An In-Depth Overview

A wirewound resistor is an essential electronic component used in a wide range of electrical circuits and applications. This resistor is known for its precise and stable resistance values, making it valuable in scenarios where accuracy and reliability are paramount. In this comprehensive guide, we will explore the different aspects of wirewound resistors, including their construction, types, applications, and key features.、

Ⅰ. Introduction to Wirewound Resistors

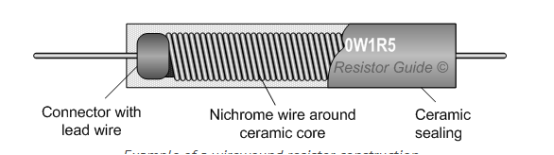

Figure1:Example of a wirewound resistor construction

A wirewound resistor is a passive two-terminal electrical component that restricts the flow of electric current. It is constructed by winding a resistive wire around an insulating core, allowing for precise control of resistance values. Wirewound resistors are used in various electronic circuits to limit current, divide voltage, or dissipate power.

Ⅱ. Construction of Wirewound Resistors

Figure2:Wire wound resistor structure

Wirewound resistors are meticulously constructed to ensure accuracy, stability, and performance. The key components of a wirewound resistor include the resistive wire, core material, winding process, and encapsulation.

Wire Material:

The resistive wire in a wirewound resistor is typically made of a high-resistance material, such as nickel-chromium (Nichrome), which has a stable resistance-temperature relationship. Nichrome wire is known for its excellent electrical properties, corrosion resistance, and ability to withstand high temperatures. Other materials, like copper-nickel alloys, can also be used for specific applications.

Core Material:

The core material, often made of ceramic or fiberglass, serves as an insulating support for the resistive wire. It maintains the spacing and geometry of the wire windings, preventing short circuits and ensuring a consistent resistance value. Ceramic cores are widely used due to their electrical insulating properties and high-temperature resistance.

Winding Process:

The resistive wire is carefully wound around the core, and the number of windings and their length determine the resistance value of the wirewound resistor. The winding process requires precision to achieve the desired resistance value and to maintain a uniform winding pattern. The wire is often wound in a spiral fashion for optimal performance.

Encapsulation and Packaging:

To protect the wire and core from environmental factors, wirewound resistors are typically encapsulated or packaged in a protective housing. The encapsulation can be made of materials like epoxy, silicone, or ceramic, depending on the specific application requirements. This housing also provides mechanical support and insulation, making the resistor robust and reliable.

Ⅲ. Types of Wirewound Resistors

Wirewound resistors come in various types to meet the specific needs of different applications. Some of the common types include:

Precision Wirewound Resistors:

Figure3:Power Wirewound Resistors

Power wirewound resistors are capable of handling high levels of electrical power. They are often used in applications where significant heat dissipation is required, such as in power electronics, motor control, and industrial equipment.

Variable Wirewound Resistors:

Variable wirewound resistors, also known as potentiometers or rheostats, have a movable wiper that allows for the adjustment of the resistance value. They are commonly used in applications where manual or remote adjustment of resistance is necessary, such as volume controls in audio equipment.

Surface Mount Wirewound Resistors:

Surface mount wirewound resistors are designed for direct placement on the surface of a printed circuit board (PCB). They are smaller and more compact than traditional through-hole resistors, making them ideal for modern electronics and automated manufacturing processes.

Ⅳ. Working Principles of the wirewound resistors

Understanding the working principles of wirewound resistors is essential to harness their functionality effectively in electronic circuits. Key aspects include resistance calculation, temperature coefficients, and power dissipation.

Resistance Calculation:

The resistance value of a wirewound resistor is determined by its length, cross-sectional area, and the resistivity of the wire material. It follows Ohm's law, where resistance (R) is equal to the resistivity (ρ) times the length (L) divided by the cross-sectional area (A):

This equation explains how the resistance value can be precisely controlled by altering the length and cross-sectional area during the manufacturing process.

Temperature Coefficients:

Wirewound resistors have temperature coefficients, which describe how their resistance changes with temperature. The temperature coefficient is expressed in parts per million per degree Celsius (ppm/°C). Low-temperature coefficients are desirable in applications where temperature stability is critical because they minimize resistance drift as the temperature changes.

Power Dissipation:

Power dissipation is a crucial consideration when selecting a wirewound resistor for a specific application. It defines the maximum power the resistor can safely dissipate without overheating. This value depends on the resistor's construction, materials, and design. Proper heat management is essential to ensure the resistor operates within its specified power rating.

Ⅴ. Applications of Wirewound Resistors

Wirewound resistors find application in a wide array of electronic and electrical systems, owing to their precision and reliability. Some common applications include:

Electronic Testing and Measurement:

Wirewound resistors are used in equipment like multimeters, oscilloscopes, and signal generators to provide precise resistance values for calibration and measurements.

Power Electronics:

In power electronics applications, wirewound resistors help manage and dissipate power in devices such as inverters, converters, and electronic loads.

Signal Conditioning:

In signal conditioning circuits, wirewound resistors are used to adjust signal levels, filter noise, and provide voltage dividers for sensor inputs.

Precision Instrumentation:

Precision instruments, including medical devices, laboratory equipment, and scientific instruments, rely on wirewound resistors to maintain high levels of accuracy and stability.

Audio Equipment:

In audio systems, wirewound resistors are found in components like volume controls, tone controls, and audio amplifiers, where precision and low noise are essential.

Ⅵ. Advantages and Disadvantages of the wirewound resistor

Wirewound resistors offer several advantages, making them suitable for various applications. However, they also have some limitations that need to be considered.

Advantages of the wirewound resistor:

High Precision: Wirewound resistors are known for their high level of precision and tight tolerance values. They provide consistent resistance over a wide range of conditions, making them suitable for applications where accuracy is critical.

High Power Handling Capacity: Power wirewound resistors can handle significant levels of electrical power, making them ideal for high-power applications.

Stability and Reliability: Wirewound resistors exhibit excellent long-term stability and reliability. They are less prone to drift in resistance values over time.

Temperature Stability: Some wirewound resistors have low temperature coefficients, ensuring that their resistance remains stable across varying temperatures.

Tolerance and Precision: Wirewound resistors are available with various tolerance levels, allowing engineers to select the appropriate level of accuracy for their specific application.

Disadvantages of the wirewound resistor:

Cost: Wirewound resistors can be more expensive compared to other types of resistors due to their precision and construction.

Size: They tend to be larger in size, which may not be suitable for compact or space-constrained designs.

Inductance: Wirewound resistors can exhibit inductance due to the coiled wire design, which may not be desirable in certain applications.

Limited Value Range: Wirewound resistors may not be ideal for applications requiring very low resistance values or very high resistance values.

Ⅶ. Key Features of Wirewound Resistors

High Precision:

One of the most significant advantages of wirewound resistors is their high precision. They offer tight tolerance values, often in the range of 0.1% to 5%, ensuring that the specified resistance closely matches the actual resistance.

High Power Handling Capacity:

Power wirewound resistors are designed to dissipate significant amounts of power without overheating. This feature makes them suitable for high-power applications, where heat management is crucial.

Stability and Reliability:

Wirewound resistors are known for their stability and reliability over time. They exhibit minimal resistance drift, ensuring consistent performance in critical applications.

Temperature Stability:

Some wirewound resistors are manufactured with low temperature coefficients, meaning their resistance remains relatively constant over a wide temperature range. This is vital in applications where temperature fluctuations can affect performance.

Tolerance and Precision:

Wirewound resistors are available in a wide range of tolerance values, allowing engineers to select the level of accuracy that best suits their needs. This flexibility is especially valuable in precision applications.

Ⅷ. Selection Criteria of the wirewound resistor

Choosing the right wirewound resistor for a specific application involves considering several important criteria:

Resistance Value:

Determine the required resistance value based on the application's needs. Wirewound resistors are available in various resistance ranges, so select one that aligns with your requirements.

Power Rating:

Consider the maximum power dissipation the resistor will encounter in your application. Ensure that the chosen resistor can handle the expected power without overheating.

Tolerance and Precision:

Decide on the required level of precision for your application. Choose a resistor with an appropriate tolerance value to meet your accuracy requirements.

Temperature Coefficient:

In applications with temperature variations, opt for wirewound resistors with low temperature coefficients to maintain stability.

Mounting Type:

Select the appropriate mounting style, such as through-hole or surface mount, based on your circuit design and available space.

Ⅸ. Customization and Specialized Wirewound Resistors

In some cases, standard wirewound resistors may not fully meet the unique requirements of a specific application. Manufacturers offer customization options to tailor wirewound resistors to specific needs. Some customization possibilities include:

Tailored Resistance Values:

Manufacturers can produce wirewound resistors with resistance values that are precisely matched to the application's requirements. This ensures a perfect fit and optimal performance.

Specialized Encapsulations:

For extreme environmental conditions or special considerations, wirewound resistors can be encapsulated with materials that offer enhanced protection and performance.

Ⅹ. Industry Standards and Certifications of the Wirewound resistor

Wirewound resistors are often subject to industry standards and certifications to ensure their quality and performance. Some commonly recognized standards and certifications include:

RoHS (Restriction of Hazardous Substances): Ensures that wirewound resistors comply with restrictions on the use of hazardous materials in electronic components.

ISO (International Organization for Standardization): ISO certification signifies compliance with international quality standards, ensuring consistent product quality.

MIL-PRF-26: A military specification for precision wirewound resistors, ensuring their reliability and performance in demanding applications.

UL (Underwriters Laboratories): UL certification verifies the safety and performance of wirewound resistors in various electrical systems.

IEC (International Electrotechnical Commission): IEC standards are globally recognized and ensure product quality and reliability.

Ⅺ. Conclusion of the Wirewound resistors

Wirewound resistors are vital in modern electronics, offering precision, reliability, and stability across various applications, particularly in power electronics, precision instruments, and audio equipment. They will continue to evolve to meet the needs of smaller, smarter, and more eco-friendly devices, maintaining their essential role in electronic design and innovation.

Related Articles

Wirewound Resistor: An In-Depth Overview