Electric Actuator: Types, Applications & Advantages

What is an Electric Actuator?

An outfit that transforms electrical energy into mechanical motion is called an electric actuator. Actuators are constantly used to control mechanical bias, similar as valves that open or near, in a range of artificial, marketable, and domestic operations, outfit or moving point placement.

.webp)

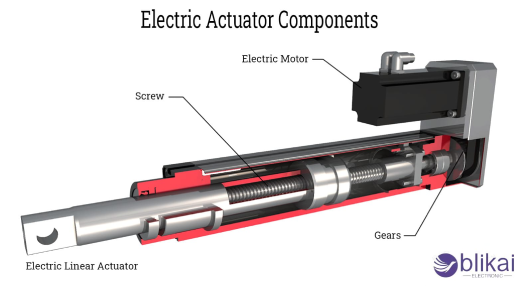

Key Components of an Electric Actuator:

1. Electric Motor: The primary source of motion; depending on the operation, this can either be a DC or AC motor.

2. Gearbox: Increases necklace while dwindling motor speed, supplying the force demanded to negotiate the intended motion.

3. Lead Screw or Ball Screw: Transforms the motor's rotating motion into direct motion.

4. Control Circuitry: Controls the motion by getting input and giving it back; this is crucial for accurate control.

5. Sensors: Feedback sensors, which include limit switches, encoders, and potentiometers, are generally employed to track position, haste, and other variables.

Types of Electric Actuators:

1. Linear Actuators:

- Description: Convert electrical energy into linear motion. They are often used to push, pull, or lift loads.

- Types:

- Rod Actuators: Feature a rod that extends or retracts to provide motion.

- Screw Actuators: Use a lead screw mechanism to generate linear motion.

- Belt Actuators: Use a belt drive mechanism to generate linear motion.

- Applications: Automated doors for robots, packing machines, medical equipment (such as hospital beds), etc.

2. Rotary Actuators:

- Description: Generates rotational motion using electrical energy.

- Types:

- Motor-Based Actuators: Employ electric motors to generate rotational motion, such as servomotors or stepper motors.

- Gear-Driven Actuators: Combining gears can reduce speed or improve torque.

- Applications: Automation of valves in robotics, conveyor systems, manufacturing, and turntables

3. Servo Actuators:

- Description: Gives exact control over acceleration, velocity, and angular or linear position by combining a motor and a feedback sensor.

- Applications: Robotics, antenna positioning, camera focusing systems, CNC machine tools, etc.

4. Stepper Motor Actuators:

- Description: Precisely controls each step's mobility using stepper motors. ideal for uses where repeatable, accurate positioning is required.

- Applications: Printers, automatic control systems, mounters, and 3D printers.

5. Piezoelectric Actuators:

- Description: It makes very tiny but accurate movements by using a piezoelectric material, which changes shape in response to an applied voltage.

- Applications: Accurate placement and nanoscale control in optical tools, microscopes, and medical apparatus.

Applications of Electric Actuators:

- Industrial Automation: For activities like assembly line fastening, lifting, and positioning, packaging, and material handling systems. as well as valve management.

- Robotics: Delivering accurate motion control to joints, fixtures, and robot arms.

- Aerospace: For mounting, flight control surfaces, and other important aviation system components.

- Automotive: For the braking, throttle control, and other systems in electric car components (such seats, windows, and mirrors).

- Medical Devices: For imaging apparatus, surgical beds, hospital beds, exoskeletons, and other assistive technology.

- Renewable Energy: For wind turbine blade control, solar panel tracking systems, and other green technology uses.

- Home Automation: Automated window shades and HVAC covers are examples of smart home appliances that are customizable.

Advantages of Electric Actuators:

1. Precision and Control: High levels of precision and control over motion, speed, and position are possible with electric actuators, particularly when combined with feedback devices like encoders or sensors.

2. Energy Efficiency: In contrast to pneumatic or hydraulic actuators, which continuously lose power, energy is only used when moving.

3. Low Maintenance: Fewer mechanical components and no fluids make them generally more reliable and easier to maintain.

4. Flexibility: It is perfect for Internet of Things applications and process automation since digital control systems may be easily integrated with it.

5. Quiet Operation: Produce less noise than hydraulic and pneumatic actuators, which makes them perfect for settings where noise pollution is an issue.

6. Environmentally Friendly: Because compressed air and hydraulic fluid are n't demanded for electric actuators, there's a lower chance of impurity or leakage.

How Electric Actuators Work:

1. Motor: The motor, which is the primary part of an electric actuator, is a type of motor that, when electrical energy is applied, produces rotary motion. Generally, a motor is a DC motor or stepper motor.

2. Mechanical Conversion: This rotational movement is also converted into direct or rotary motion, depending on the design of the actuator. This conversion can be done using gears, screws, belts, or cams.

3. Control System: Generally, electric actuators are equipped with a control system, similar as a microcontroller, to regulate force, motion, speed, and direction.

FAQs

1. What is an Electric Actuator?

An outfit that transforms electrical energy into mechanical motion is called an electric actuator. It's employed to move or regulate a system or medium, like conforming shock absorbers or opening valves or manipulating robot arms.

2. How Does an Electric Actuator Work?

An electric motor is used by an electric actuator to induce direct or rotary motion. The motor powers a screw medium or gearbox that transforms the motor's gyration into the necessary motion which may be either rotational or direct.

3. What are the Types of Electric Actuators?

There are two main types:

- Rotary Actuators: They're generally employed in valve robotization systems to induce rotary motion.

- Linear Actuators: They induce direct motion and are generally set up in manipulators, robotics, and other ministry.

4. What are the Applications of Electric Actuators?

Multitudinous operations need for motorized actuators, similar as:

- Industrial Automation: Conveyor belts, dampers, and control valves.

- Robotics: Moving robot arms or joints.

- Automotive: Windows, mirrors, and seats can be adjusted.

- Home Automation: Adjusting window coverings, curtains, or thermostats.

- Aerospace and Defense: Examining the wharf gear or maneuvering shells.

5. What are the Advantages of Electric Actuators?

- Precision and Control: Excellent perfection in controlling speed and position.

- Energy Efficiency: Only consume power when moving.

- Ease of Integration: Simple to integrate with electronic control systems.

- Low Maintenance: With fewer machine parts, wear and tear are decreased.

- Environmentally Friendly: It helps lower the possibility of leaks or tumbles because neither compressed air nor hydraulic oil painting are demanded.

6. What are the Disadvantages of Electric Actuators?

- Power Requirements: Perhaps a lot of electricity is demanded.

- Limited Force Output: Generally produce less force compared to hydraulic actuators.

- Environmental Limitations: May not work correctly in settings with high heat or explosives unless it is made expressly for such circumstances.

7. What Factors Should be Considered When Choosing an Electric Actuator?

- Load Requirements: Determine the necessary necklace or force.

- Speed and Precision: Consider the required speed and accuracy of the motion.

- Power Supply: Ensure compatibility with available power sources.

- Environment: Evaluate the environment (temperature, humidity, explosion risk, etc.).

- Duty Cycle: Take functional time and frequence into consideration.

8. How Do Electric Actuators Compare to Hydraulic and Pneumatic Actuators?

- Electric Actuators: Offer accurate, energy-saving management, but their power output is constrained.

- Hydraulic Actuators: Offer a strong actuation force, making it applicable for heavy- duty operations; nevertheless, it needs hydraulic fluid and ongoing keep.

- Pneumatic Actuators: It has a straightforward design, quick response times, but is less precise and might need nonstop air consumption.

9. What Maintenance is Required for Electric Actuators?

Electric actuators frequently do not need important conservation, but they should still be checked from time to time to look for signs of overheating or odd noise, as well as wear and tear and gash on the electrical connections and moving corridor.

10. Can Electric Actuators be Used in Hazardous Environments?

Yes, still in order to help sparks or explosions, they must be especially made for dangerous areas and pukka guards must be installed.

11. What is the Typical Lifespan of an Electric Actuator?

The operation, terrain, and frequence of use all affect how long an electric actuator lasts. Under typical circumstances, the service life may span five to twenty years or longer.

12. Can Electric Actuators be Controlled Remotely?

Indeed, control systems can incorporate electric actuators for remote operation and monitoring; these systems generally employ digital communication protocols like Ethernet, Profibus, or Modbus.

Related Articles

Piezoelectric Actuator transducer : Principle & Its Applications

Door Actuators: Types, Applications & Advantages

Need Actuator Valves? What You Should Know!

What Mechanical Actuator is and How it works

Varieties of Electrical Wires and Cables

Choose a Low Voltage Transformer: Comprehensive Guide

Current Transformers:Princeple,Types,Application and FAQ

SN6505BDBVR Transformer Driver: Features, Application and Datasheet

Transformer Core Faults: Hazards, Causes, Types, Testing, and Remediation

What are Audio Transformers for?

How Do Motion Sensors Work? Types & Applications

IMU: How Does It Enable Precise Motion Tracking?

How to Test a Hard Start Capacitor [Complete Guide]

A Primers on Circulator and Isolators