Need Actuator Valves? What You Should Know!

One tool for managing fluid flow is an actuator valve. Actuators are gases or liquids that act by blocking, opening, or shutting passages. Actuator valves are extensively employed in numerous automation and industrial applications.

Types of Actuator Valves

- Electric Actuator Valves: The electric actuator drives the valve with an electric motor. It's applicable for operations demanding accurate automatic valve positioning and offers perfection control.

- Pneumatic Actuator Valves: Compressed air is used by curvaceous actuators to operate the valve. They're well-liked in high-cycle operations like manufacturing because of their responsibility and quick functioning.

- Hydraulic Actuator Valves: The valve is moved by hydraulic actuators using hydraulic oil painting. high power and heavy duty operations, like in construction outfit.

- Manual Actuator Valves: The operation of a valve using a homemade actuator requires mortal labor. Easy and provident Ideal for uses where robotization isn't necessary.

- Solenoid Actuator Valves: An electromagnetic coil is used by the solenoid actuator to move the valve. Perfect for quick on/ off control in systems that need to reply snappily and with great trustability.

Key Features of Actuator Valves to Consider

- Precision: Precision is crucial for accurate control and operation. Actuators with high precision ensure consistent performance and are ideal for applications requiring detailed adjustments and exact positioning.

- Speed: The actuator's speed controls its reaction and movement rates. Faster actuators are needed for applications that need quick actuation, including robotic operations or high-speed automation.

- Force Capacity: The greatest load that an actuator can sustain is indicated by its force capacity. It is imperative that heavy-duty applications have a high load capacity. This guarantees dependable operation in challenging circumstances and with large loads.

- Durability: An actuator's adaptability to external influences and wear and tear is measured by its durability. Strong actuators, particularly by grueling or high- cycle situations, offer long- term responsibility and minimize conservation conditions.

- Energy Efficiency: The effectiveness of an actuator's energy application is measured by its energy effectiveness. Effective actuators lower functional costs and are better for systems where energy consumption is a critical concern.

How do actuator valves work?

Actuators are used in valves to regulate the position of the valve, which in turn regulates the inflow of a fluid(either gas or liquid) via the valve. Then is a step- by- step breakdown of how they operate:

1. Actuator Signal: When a control signal is given to the actuator, the procedure begins. The type of actuator being employed determines whether the signal is electric, curvaceous , or hydraulic.

2. Actuator Response: The signal is entered by the actuator, which also produces mechanical movement. The type of actuator determines the method of movement:

- Electric Actuators: A shaft can be rotated or moved by an electric motor.

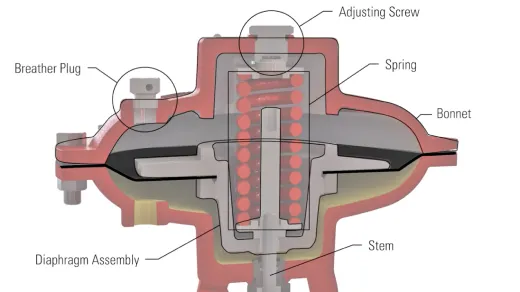

- Pneumatic Actuators: To move a diaphragm or piston, use compressed air.

- Hydraulic Actuators: To power pistons or other mechanical corridor, use hydraulic fluid.

3. Valve Movement: The actuator transfers its mechanical movement to the valve medium. This movement adjusts the valve's position, which could be:

- Open: Allowing fluid to flow through the valve.

- Closed: Blocking the flow of fluid.

- Partially Open: Regulating the flow to a specific level.

4. Flow Regulation: When a new position for the valve is reached. The valve offers accurate control over the system's operating characteristics by regulating the fluid's inflow rate and pressure as it passes through it.

5. Feedback Loop: Information about the position of the valves is transferred back to the control system by a feedback medium seen in numerous systems. This guarantees that the valve is in the proper position and permits any necessary changes.

6. Operation Completion: When the required position of the valve is reached. This is the position the valve will stay in until a fresh signal is received. In response to ongoing signals or modifications in the system's circumstances, the actuator keeps controlling the valve position.

Applications of Actuator Valves

- Industrial Automation: In industrial automation, valve actuators are crucial because they regulate fluid flow throughout manufacturing. It facilitates accurate material control. This makes it possible for automated systems to serve effectively and dependably, similar as robotic assembly lines and conveyor belts.

- Water Treatment: Actuators for valves control the inflow of water through different stages in water treatment shops, similar as filtration and sanctification. They're necessary to keep the pressure and inflow rate constant. This is essential for meeting legal conditions, guaranteeing effective water treatment, and maintaining quality control.

- HVAC Systems: Because they regulate the inflow of refrigerant and air in the HVAC system, valve actuators are pivotal factors. Keeping the right temperature and tailwind requires precise control. enhancing system effectiveness as a whole to guarantee a cozy interior climate in homes and businesses.

- Oil and Gas: In the oil and gas sector, actuator valves are crucial. They regulate the hydrocarbons' passage through processing machinery and pipelines. They must contend with elevated temperatures and pressures. ensuring effective and safe functioning in challenging circumstances. To keep production going and stop leaks, this is crucial.

- Pharmaceuticals: Actuator valves regulate the inflow of liquids and feasts throughout the manufacturing process in the pharmaceutical assiduity. Precise dosing and mixing are essential for conserving product quality and fulfilling strict assiduity conditions, which guarantees the pharmaceutical product's safety and effectiveness.

Choosing the Right Actuator Valve

- Understand the Application Requirements: Assessing the requirements of your particular operation is the first step towards choosing the applicable actuator valve. This covers the range of temperatures, pressure, and fluid type. Accurate understanding ensures the actuator valve will perform effectively and meet operational needs.

- Evaluate Valve Compatibility: Verify that the actuator valve is compatible with the parts of the current system. This includes determining the valve's size. Smooth integration into the system and the avoidance of installation issues are ensured by compatibility of connection type and material.

- Consider Actuator Type: The advantages of various actuator types—hydraulic, pneumatic, and electric—vary. Make your decision based on elements including surroundings, significant need, and response time. Selecting the appropriate type of actuator guarantees optimal efficacy and efficiency for your application.

- Assess Control Requirements: Ascertain the degree of control necessary for your particular application. Think about using positioners and sophisticated feedback valves for accurate automation and control. For simpler needs, basic on/off control may suffice, affecting both performance and cost.

- Review Maintenance and Durability: Examine the actuator valve's longevity and anticipated maintenance needs. Long-term operating expenses can be decreased and reliability increased by choosing a valve with a sturdy design and little maintenance needs; this is particularly true in difficult situations.

Installation and Maintenance Tips of Actuator Valves

- Proper Installation Procedures: Actuator valve installation needs adherence to the manufacturer's instructions. For optimal performance, make sure the valve is firmly placed and positioned to prevent leaks or misalignment. By taking these actions, you may support the system's optimal performance and long-term dependability.

- Check for Compatibility: Check that the actuator valve satisfies all system requirements, such as the fluid type, temperature limit, and pressure rating. Checking for compatibility will shield the valve from harm, improve its performance, lower the chance of failure, and prolong the life of the systems and valves.

- Regular Inspection and Testing: Conduct routine examinations and performance assessments of the actuator valve. Regular maintenance helps identify and address issues before they become more serious, which lowers the cost of repairs and guarantees continuous operational reliability. It does this by looking for early indicators of wear, damage, or failure.

- Clean and Lubricate: By maintaining the actuator valve clean and well oiled, you can maintain it. Premature wear and impaired valve function might result from dirt accumulation or inadequate lubrication. The valve's lifespan can be increased and correct performance can be maintained with routine cleaning and lubrication. particularly in arid or severe conditions.

- Monitor Performance: Keep an eye on the actuator valve's performance at all times to spot any irregularities, like strange noises or slow response times. This makes it possible to intervene promptly, guards against potential system failures, and guarantees that the actuator valve performs well for the purpose for which it was designed.

Advantages of Actuator Valves

- Remote Operation: Permits remote command Boost convenience and safety.

- Automation: Able to be automated by integration with control systems.

- Precision: Provides accurate control over fluid flow.

- Safety: Lessens the need for human intervention in dangerous situations.

What are the common issues with actuator valves?

- Leakage: Can occur due to worn seals or improper installation.

- Failure to Operate: May be brought on by a malfunctioning actuator or a control signal.

- Sticking: Lack of lubrication or grime can cause mechanical parts to cling.

- Inaccurate Control: May result from faulty actuators or control systems.

Related Articles

Piezoelectric Actuator transducer : Principle & Its Applications

What Mechanical Actuator is and How it works