What is a Piezoelectric Transducer?Features, Specification and Applications

In our daily lives, we encounter numerous scenarios requiring the measurement of physical quantities such as mechanical stress on metals, temperature, and pressure levels. In these situations, we rely on devices capable of quantifying these variables in units and scales familiar to us. The transducer is one of the most useful equipment for these kinds of jobs. A transducer is an electrical device that is capable of converting a variety of physical quantities into electrical signals that are proportionate, usually in the form of voltage or current. Out of all the transducers that are out there, this article focuses on explaining the fundamentals and uses of piezoelectric transducers.

A piezoelectric transducer: what is it?

An electrical device that can convert different physical quantities into electrical signals that may be measured is called a piezoelectric transducer. To be more precise, it works by using the special qualities of piezoelectric materials to translate mechanical impulses into equivalent electrical signals. For this reason, a transducer that uses the piezoelectric effect is called a piezoelectric transducer.

Piezoelectricity, the phenomenon where the application of mechanical stress or strain generates the development of an electric voltage commensurate to the applied stress, is demonstrated by piezoelectric materials. Voltage measuring tools can be used to quantify the resulting electric voltage, which will help determine the amount of stress or strain applied to the material.

Types of Piezoelectric Materials

Several types of piezoelectric materials exist:

Quartz, Rochelle salt, topaz, minerals in the tourmaline group, and some biological materials like silk, wood, enamel, bone, hair, rubber, and dentin are all found naturally.

Artificially manufactured materials include lead-free piezoelectric ceramics such as polyvinylidene difluoride (PVDF or PVF2), barium titanate, lead titanate, lead zirconate titanate (PZT), potassium niobate, lithium niobate, and lithium tantalate.

But not every piezoelectric substance can be used to create piezoelectric transducers. These materials need to fulfill certain requirements in order to be suitable for transducer applications. Materials used for measurement should be able to withstand severe humidity and temperature fluctuations, be highly output-level capable, and be able to take on a variety of shapes without losing any of their original characteristics.

Unfortunately, no single piezoelectric material possesses all of these desirable properties. Quartz, for instance, is a highly stable crystal readily available in nature, but it yields relatively low output levels. Rochelle salt, while providing the highest output values, is sensitive to environmental factors and cannot operate beyond 1150°F.

Function of a Piezoelectric Transducer

The fundamental idea of piezoelectricity underpins how a piezoelectric transducer works. Usually, a tiny layer of conductive material, like silver, is applied to the surfaces of the piezoelectric material, which is often quartz. Ions in the material move away from one conducting surface and towards the other when tension is applied. Consequently, this movement results in the generation of charge. This charge serves as a measure of the applied stress, with the polarity of the produced charge contingent upon the direction of the applied stress. Stress can manifest in two primary forms: compressive stress and tensile stress.

Piezoelectric Transducer Equation

The alignment of the crystal also impacts the voltage produced. The crystal within a transducer can be set up in either a longitudinal or transverse configuration.

Longitudinal versus Transverse Influence

In the longitudinal scenario, the generated charge is represented as

Q = F * d

Where F denotes the applied force, and d represents the piezoelectric constant of the crystal.

For quartz crystals, the piezoelectric constant d is approximately 2.3 * 10^-12 C/N.

In the transverse case, the generated charge is given by

Q = F * d * (b/a)

When the b/a ratio exceeds 1, the charge generated by the transverse alignment surpasses that of the longitudinal configuration.

Piezoelectric Transducer Configuration

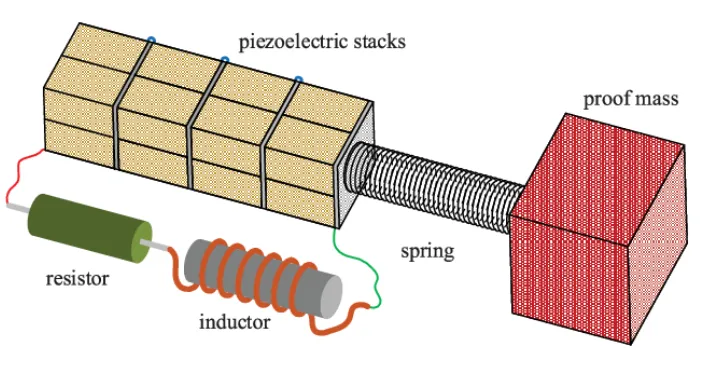

The following graphic will help you understand how a basic piezoelectric transducer works.

In this instance, a silver-coated quartz crystal acts as a sensor, producing a voltage when stress is applied. A charge amplifier is employed to gauge the produced charge with minimal dissipation. To maintain very low current draw, the resistance R1 is set to a high value. Additionally, the capacitance of the connecting lead wire between the transducer and piezoelectric sensor influences the calibration. Hence, the charge amplifier is typically positioned in close proximity to the sensor.

So, mechanical stress in a piezoelectric transducer generates an electric voltage in response, which is then amplified by a charge amplifier and used for stress calibration.

Ultrasonic Piezoelectric Transducer

The opposite piezoelectric effect is necessary for the operation of an ultrasonic piezoelectric transducer. In this phenomena, a piezoelectric material undergoes physical distortions proportionate to the applied charge when an electric current is supplied to it. Below is a schematic of the ultrasonic transducer.

A quartz crystal is positioned in this configuration between two metal plates, A and B, that are connected to the transformer's primary winding, L3. The electronic oscillator is inductively connected to the transformer's primary winding. The electronic oscillator is coupled to the coils L1 and L2, which make up the transformer's secondary winding.

The oscillator produces high-frequency alternating voltage pulses at a frequency represented by f=1÷(2π−L1C1) when the battery is turned on. As a result, L3 experiences the induction of an electromotive force (e.m.f.), which is subsequently transferred to the quartz crystal through plates A and B. The crystal experiences alternating contractions and expansions as a result of the opposite piezoelectric effect, which starts mechanical vibrations.

When the electronic oscillator's frequency coincides with the quartz's inherent frequency, resonance happens. At this juncture, the quartz crystal emits longitudinal ultrasonic waves characterized by significant amplitude.

Piezoelectric Transducer Utilizations

Due to the inability of piezoelectric materials to measure static values, their primary applications include the measurement of surface roughness, implementation in accelerometers, and usage as vibration sensors.

They find deployment in seismographs to detect vibrations in rocketry.

They are integrated into strain gauges to assess force, stress, and vibrations, among other factors.

In the automotive sector, they are employed to monitor engine detonations.

They are utilized in medical settings for ultrasonic imaging purposes.

Advantages and Disadvantages of Piezoelectric Sensors

The following is a summary of the benefits and limitations of piezoelectric transducers:

Advantages of Piezoelectric Sensors

These transducers are active, requiring no external power source for operation, thereby being self-sustaining.

Their high-frequency response renders them suitable for diverse applications.

Disadvantages of Piezoelectric Sensors

The behavior of the transducer can be influenced by temperature and environmental conditions.

Their capacity to solely measure changing pressure renders them ineffective in capturing static parameters.

In conclusion, the aforementioned content encapsulates insights into Piezoelectric Transducers, encompassing their operational principles, formulas, circuitry, advantages, limitations, and applications. Given the array of applications discussed, have you utilized piezoelectric transducers in any particular application? What was your experience?