Chassis Ground Explained: Preventing Faults in Electronics

Introduction to Chassis Ground

Grounding is an essential principle in electronics that offers functionality and safety. Out of all the available grounding methods, chassis ground is particularly important in equipment protection, reduction of electrical noises, and elimination of hazards. Chassis ground is something that every person involved with electronic or electrical equipment should understand, regardless of whether you design circuits, build systems, or debug faults.

What Is Chassis Ground?

Chassis ground is a grounding method whereby the metal case or frame (the chassis) of an electronic device is connected to the ground potential. This is necessary so that any stray voltages or fault currents are conducted safely away, away from sensitive components and users. Chassis ground is a reference point in the equipment itself, as opposed to earth ground, which is connected directly to the physical earth.

The chassis may or may not be connected to earth ground, but it typically serves as electrical hindrance shielding and as a safety conduit for fault currents. Chassis ground is important for numerous electronic systems, including computers, boxes, and artificial ministry, to operate steadily.

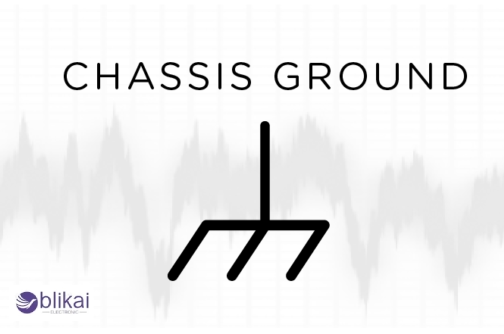

Chassis Ground Symbols in Circuit Diagrams

When reading circuit schematics, chassis ground symbols are vital for understanding how a system manages grounding:

- The most common symbol is a horizontal line with three descending lines below it, representing a grounded enclosure.

- The IEC standard typically uses a variation with horizontal bars.

- ANSI standards may depict chassis ground slightly differently but with similar intent.

Functions of Chassis Ground in Electronics

The functions of chassis ground extend far beyond simple safety:

1. Electromagnetic Interference (EMI) Reduction

The chassis ground acts as a shield that absorbs and redirects electromagnetic interference away from internal circuits, ensuring signal integrity.

2. Electrostatic Discharge (ESD) Protection

It offers a safe conduit through which static electricity can be discharged, preventing damage to sensitive electronic parts by ESD.

3. Electrical Safety

In the event of insulation failure or accidental contact with live parts, chassis ground offers a low-resistance path to prevent electric shock or equipment damage.

4. Signal Reference

In some systems, chassis ground serves as a stable reference voltage point, especially for analog and mixed-signal designs.

Chassis Ground vs. Earth Ground vs. Signal Ground

While these terms are sometimes confused, they serve different purposes:

- Chassis Ground: Connects the equipment’s metallic body to a ground reference.

- Earth Ground: Connects the system directly to the earth via grounding rods or conductors.

- Signal Ground: Serves as a reference point for low-level signals within a circuit, often isolated from safety grounds.

Common Applications of Chassis Ground

Chassis ground is a very common practice in many industries to provide safety, interference reduction and system stabilization. Some of its most important uses in various disciplines are given below:

Consumer Electronics

Chassis ground is important in consumer appliances such as notebook computers, desktop computers, televisions, video game consoles, and home theater systems to ensure that sensitive internal circuits are not affected by electromagnetic interference (EMI) or radio frequency interface (RFI). Grounding the metallic enclosure of the device allows the manufacturers to ensure that the noise generated externally does not couple within the signal paths and, therefore, assures signal integrity. Also, chassis grounding helps diminish the chance of electric shock to users by securely diverting any fault current that may flow toward accessible surfaces.

Industrial Control Systems

Chassis ground is also necessary in industrial settings where electrical noises are likely to be high. PLC panels, robotic automation lines, motor control centers and manufacturing equipment all use chassis ground to stabilize reference potentials and avoid spurious operation due to changes in voltage or transient noise. A good grounding system will ensure that sensitive control signals are not affected by large power surges or EMI found in industrial facilities, thus increasing operating reliability and decreasing downtime.

Communication Equipment

In the case of radios, transmitters, receivers, routers, and base stations, it is important to have a clear transmission of signals. Chassis ground also assists these systems in rejecting unwanted noise and reduces electromagnetic coupling between circuits, which can limit transmission quality. In high-frequency systems (RF and microwave systems), good chassis grounding practice will aid in keeping the signal purer and provide a better-controlled impedance, which is critical to optimum communication system performance.

Power Supply Units

Chassis ground serves an important safety purpose in power supplies ( desktop adapters to large industrial rectifiers ). This is achieved by bonding the enclosure to the earth's ground. Thus, any internal insulation fault or leakage current is harmlessly diverted before reaching the user. This is needed to comply with international safety standards (IEC and UL certifications, etc.) as well as to assure that power conversion circuits can be operated without adding hazardous voltages to the enclosure. Also, grounding minimizes the emissions of EMI, which makes power supplies achievable with the regulation of EMC (Electromagnetic Compatibility).

Automotive Electronics

Contemporary automobiles rely heavily on chassis ground by using the metallic body of the car as a common return pathway of electrical systems. This architecture eases the wiring efforts, less copper is required, and circuit reliability is guaranteed over a large number of subsystems, including lighting, infotainment, engine control, and safety systems like airbags and ABS. Grounding in automotive chassis also serves to stabilize voltages across the car and suppress noise coupling into the car ignition systems or other external noise sources.

How to Properly Connect Chassis Ground

Proper grounding techniques are crucial for both safety and performance:

PCB Layout Recommendations

Route ground planes carefully to minimize noise.

Connect chassis ground near cable entry points to shield against EMI.

Single-Point vs. Multi-Point Grounding

Single-Point Grounding: Ideal for low-frequency, sensitive circuits.

Multi-Point Grounding: Better for high-frequency systems to reduce impedance at different frequencies.

Contact Resistance

Ensure secure, clean connections with low-resistance bonding to avoid floating grounds.

Verification and Testing

Use multimeters and ground testers to confirm proper connections and continuity across the chassis ground network.

Chassis Ground Safety Considerations

Safety standards are critical when implementing chassis ground:

Compliance with Standards

Follow relevant regulations such as:

UL (Underwriters Laboratories)

IEC (International Electrotechnical Commission)

CE Marking (Conformité Européenne)

Leakage Current Management

Use proper insulation and grounding design to control leakage currents and ensure user protection.

Insulation and Fault Protection

Ensure that chassis ground connections are robust and properly bonded to protect against insulation failures.

Common Mistakes and Troubleshooting Chassis Ground Issues

Despite its importance, improper chassis ground implementation can cause serious issues:

Ground Loops

Multiple ground paths can create loops that induce noise and hum in sensitive circuits.

Solution: Use proper grounding topology and isolation techniques.

Noise Coupling

Poor shielding or improper ground bonding can lead to unwanted signal interference.

Solution: Improve shielding, use differential signaling, and ensure tight bonding.

Real-World Case Studies

Audio systems Ground loops can result in a 60Hz hum that is usually easy to hear.

Poor chassis grounding in industrial systems may result in communication failures in PLC.

Conclusion

The chassis ground is a foundation block of safe and good electronic design. It offers highly necessary paths to fault currents, protects delicate circuits against noise, and makes sure that safety standards are acceptable. If you design consumer electronic products, industrial systems, or communication equipment, a good grasp of the concepts of chassis ground will lead to a more robust and reliable design. With some careful planning and execution, engineers and technicians may eliminate the possibility of these common failures and help the equipment operate longer with less downtime due to chassis ground connection issues.

Frequently Asked Questions (FAQ)

1. What is the main purpose of chassis ground in electronics?

Chassis ground prevents faults in electronic circuits, EMI, static discharge and electromechanical safety.

2. How is chassis ground different from earth ground?

Chassis ground connects to the device’s frame or enclosure, while earth ground connects directly to the physical earth for safety.

3. What problems can improper chassis grounding cause?

Poor chassis grounding can lead to electrical noise, ground loops, equipment malfunctions, safety risks, and even electric shocks.

4. How can I test if the chassis ground is properly connected?

With a multimeter, test to see that there is continuity between chassis and ground point; good grounding exhibits very low resistance.

5. In which devices or industries is chassis ground commonly used?

Chassis ground is very common in consumer electronics, industrial equipment, vehicles, medical equipment, power supplies and aerospace systems.

6. What symbol is used for chassis ground in circuit diagrams?

Chassis ground is usually shown as a horizontal line with multiple descending lines, following IEC or ANSI standards.

7. How does chassis ground help reduce electromagnetic interference (EMI)?

Chassis ground shielding is commonly used for sensitive components, absorbing unwanted electromagnetic energy and reradiating it by the chassis ground without passing through the sensitive circuits.

8. How does chassis ground protect against electrostatic discharge (ESD)?

It safely directs static electricity away from sensitive components, preventing ESD damage during operation or handling.

Related Articles

Why Ground Fault Circuit Interrupter Keeps Tripping [Fix Guide]

Arc Fault vs Ground Fault Circuit Interrupter: Key Differences

How to Reset Ground Fault Circuit Interrupter (GFCI) Safely

How to Read Ground Circuit Symbols in Circuit Diagrams [Guide]

STM8S005K6T6C Microcontroller: Features, Apps & Datasheet Insights

Transformer Core Faults: Hazards, Causes, Types, Testing, and Remediation

Arduino vs. Raspberry Pi: An In-Depth Contrast

Comparing FPGA vs Microcontroller: Optimal for Your Needs?

TXB0104PWR Review: Overview, Features, and Applications

W25Q80DVSNIG Review: Features, Applications and Datasheet

STM32F030F4P6 Microcontroller: Overview, Applications, and Datasheet

Exploring Testing Methods: Types, Pros and Cons

Different Types of Electric Motors All Explained

What’s the Difference Between LR44 and 357 ?