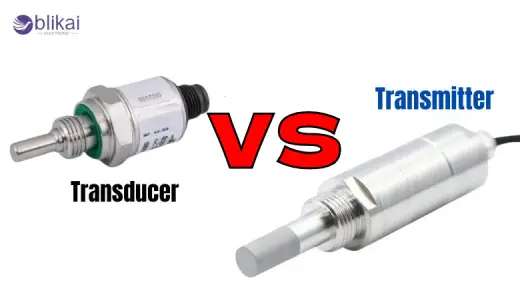

Transducer vs Transmitter: Key Differences, Functions & Applications

Introduction to Transducers and Transmitters

Sensors, transducers and transmitters are important characteristics of modern electronic systems and industrial automation. The terms transducer and the term transmitter are commonly encountered by engineers, technicians and students, and yet they are not equivalent. A transducer is in charge of transferring one type of energy to another, whereas a transmitter transforms this raw input signal to a universal form capable of being transported to controllers or alarm systems.

What is a Transducer?

An electronic device, which changes energy to and from, is called a transducer. In instrumentation, it tends to transmit a physical quantity (like temperature, pressure or light) into an electric signal.

Common Types of Transducers

Resistive Transducers: Are sensitive to changes in temperature, pressure or displacement.

Capacitive Transducers: Use capacitive changes due to movement or dielectric change.

Inductive Transducers: A mechanical displacement to an inductance change conversion.

Piezoelectric Transducers: Produce an electric charge when a piezoelectric material is under mechanical stress.

Optical Transducers: Convert optical signals into electrical signals (e.g., photodiodes, phototransistors).

Examples

- A thermocouple is used to transform heat into a voltage signal.

- The microphone converts sound into electric impulses.

- A strain gauge measures mechanical strain and gives a change in resistance.

Thus, transducers are the primary sensing elements in any measurement system.

What is a Transmitter?

A transmitter is usually an electronic system that operates to process the signal provided by a transducer or sensor and transforms that signal into a standardized output that can be transmitted a long distance or further. The most typical output signals are 420 mA current loops or 010 V voltage signals used in industrial automation.

Functions of a Transmitter

- Amplifies weak signals from the transducer.

- Conditions the signal to remove noise.

- Converts the signal into a standard output format.

- Ensures stable transmission over long cables.

Examples

- A pressure transmitter converts pressure measured by a sensor into a 4–20 mA signal.

- A temperature transmitter takes a thermocouple’s voltage and outputs a standardized signal.

- A flow transmitter processes data from a flow sensor for industrial monitoring.

Transmitters serve as the bridge in-between sensors and controllers.

Transducer vs Transmitter: Key Differences

Even though the two are related, transducers and transmitters are not interchangeable. Their distinctions can be described as functionality, signal processing and applications.

|

Aspect |

Transducer |

Transmitter |

|

Definition |

Converts physical quantity into an electrical signal. |

Converts raw sensor signal into a standardized, transmittable output. |

|

Signal Type |

Produces weak, raw, and often non-standardized signals. |

Produces strong, standardized signals (e.g., 4–20 mA, 0–10 V). |

|

Role |

Primary sensing element. |

Secondary device for signal conditioning and transmission. |

|

Complexity |

Simple device with basic conversion. |

More complex with amplification and processing circuits. |

|

Power Requirement |

Often passive (no power needed for operation). |

Requires external power for signal processing. |

|

Applications |

Sensors in medical, industrial, and consumer electronics. |

Industrial automation, remote monitoring, control systems. |

|

Example |

Thermocouple, microphone, strain gauge. |

Pressure transmitter, temperature transmitter. |

Functions of Transducers

Transducers form the foundation of sensing technology. Their key functions include:

- Signal Conversion – Converting physical energy into measurable electrical signals.

- Energy Transformation – For example, converting mechanical stress into electrical charge.

- Accuracy in Sensing – Giving the exact value of actual physical values.

- Versatility – Applied in the mechanical, thermal, optical and acoustic fields.

Without transducers, measurement systems cannot capture physical data.

Functions of Transmitters

Transmitters extend the usefulness of transducers by making signals reliable and standardized. Their main functions are:

- Signal Amplification – Amplifies weak signals to be processed.

- Noise Reduction – Reduces undesired interference.

- Standardization – Reduces raw signals into common industrial formats.

- Long-Distance Transmission: The system enables the monitoring and control over long distances.

- Integration – Does not have problems with interfaces with PLCs (Programmable Logic Controllers) and DCS (Distributed Control Systems).

Applications of Transducers

Transducers feature strongly in contemporary technology as they are an important connection between physical systems/electronic systems.

Industrial Automation: Elsewhere in manufacturing plants or factories, force sensors, torque measurement transducers, and vibration monitors are necessary transducers. They make machines safe to operate in limited conditions, identify wear on machines at an early stage and facilitate predictive maintenance programs.

Medical Equipment: Healthcare is an industry of precision. Examples of transducers can be found in ECG sensors used to measure the activity of the heart, ultrasound probes to map sound waves into images, or a patient monitoring system to measure vital signs in real-time. These devices are not only able to improve the accuracy of diagnostic procedures, but also guarantee a higher safety for the patient.

Consumer Electronics: Consumer devices are dependent on transducers. Smartphones have microphones that receive audio as an electrical signal, camera light beams work to regulate the light intensity so as to take clear pictures, and touch screens (capacitive) enable contact of a finger with the screen to translate into workable digital signals. They are necessary in order to interact with modern devices; otherwise, user interaction with them would not be possible.

Automotive and Aerospace: The use of transducers in the field of transportation is applied to provide safety and performance. Fuel level measurements give accurate information to maximize output, tire pressure sensors enhance the road safety conditions, and altitude sensors aid in navigation and control. These applications are very essential to reliability in vehicles, aircraft, and space cars.

Transducers also provide the raw information that today is required to operate the modern control systems in a smarter way, so that more intelligent decisions can be made.

Applications of Transmitters

In fields that need the accuracy and constant communication of data, transmitters are a vital requirement. Transmitters do not just convert physical signals, as do transducers, but process the information and feed it out over long distances to the monitoring systems and controls.

Process Industries: In chemical plants, food production lines, and water treatment facilities, transmitters measure and relay parameters such as pressure, flow, and temperature. This ensures production quality, process stability, and compliance with safety regulations.

Energy Sector: HVAC systems transmitters work in smart buildings, which have constant temperature, humidity, and air quality monitoring. This information allows energy-efficient climate control of the buildings, which creates cost savings without compromising comfortable indoor conditions.

Building Automation: HVAC systems transmitters work in smart buildings, which have constant temperature, humidity, and air quality monitoring. This information allows energy-efficient climate control of the buildings, which creates cost savings without compromising comfortable indoor conditions.

Remote Monitoring: Transmitters are the key smart monitoring solutions in the era of IoT. They push environmental information in weather stations, industrial machinery, or agricultural monitors to the cloud, where it is able to be productively examined remotely. Such a possibility enables large-scale monitoring to be more scalable, affordable, and trustworthy.

Transmitters optimize industrial automation, heighten safety, and help meet the ever-increasing needs of connected, smart systems by ensuring proper and prompter sensor detail communication.

Transducer + Transmitter Working Together

Trans into the real world transducers and transmitters operate in tandem./divNETTA-p beliecash gravity, and everything changes. The transducer picks up a physical energy, converts it, and it is then processed by the transmitter in a usable way.

For example:

- A pressure transducer placed in a pressure measurement system is a type of transducer that picks up a force generated and provides a small electrical output signal.

- A pressure transmitter then amplifies this, and a 4-20mA current loop is provided to a control system.

Such integration makes it precise, stable and able to work in industrial systems.

Conclusion

Transducers and transmitters are both critical components to the electronic measuring system but with different and separate usage. The part that causes the physical changes to be recorded is the transducer and the part that will ensure that the above data is processed reliably, amplified and transferred is the transmitter.

Selection of devices is strictly application dependent: transducers to be used in raw sensing, transmitters in standardized monitoring and control. They are collectively the mainstay of contemporary automation, medical equipment and electronic systems.

Frequently Asked Questions (FAQ)

What is the main difference between a transducer and a transmitter?

It is the transducer which converts physical energy to electric energy, and a transmitter which converts the raw signal to a standardised one which ought to be monitored.

Can a transducer work without a transmitter?

Yes, but it can be weak, noisy and not so good to be able to transmit it over a long distance.

Are all transmitters based on transducers?

Yes, transmitters are based on the transducers to come up with input signals and then carry them.

Where are transducers and transmitters commonly used?

Transducers are widely used in medical and consumer devices, while transmitters dominate in industrial and automation systems.

Which is more important, the transducer or the transmitter?

The two are equally critical as the transducer measures raw data, whereas the transmitter makes it usable to be used in control and monitoring.

Some images are sourced online. Please contact us for removal if any copyright concerns arise.

What Is CBB61 Capacitor - Function and Applications

Motherboard: The Core of Computer Hardware

What are Audio Transformers for?

Regulated vs Unregulated Power Supply: What's the difference?

Varieties of Electrical Wires and Cables

What is a Multiplexer and How Does it Work? [Explained]

LMC555CN Timer: Applications, Features, and Datasheet

What is a RF Modulator? Everything You Need to Know

MX25U12832FM2i02 IC Chip: Features, Applications and Datasheet

What is a High Pass Filter? Features, and Applications