What is an Actuator? All You Need to Know

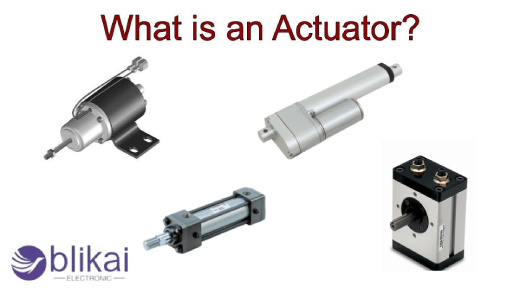

What is an Actuator?

A device that transforms energy into mechanical motion is called an actuator. It's a pivotal element of numerous bias and systems. It facilitates carrying out manual labor. Robots, industrial machinery, automobile systems, home automation systems, etc. all frequently employ actuators.

Specifications of Actuators

-Force/Torque Output: The highest force or necklace that can be generated by the selection.

-Speed: The rate of motion or rotation of the actuator.

-Stroke Length (for linear actuators): The furthest length of a straight line that a selector can go.

-Duty Cycle: The maximum frequency at which a selector may operate without breaking down or becoming too hot.

-Control Method: The type of signal or system (digital, analog, PWM, etc.) controlling the agitation of the selection.

Key Components of Actuators

-Power Source: The quantum of energy demanded to power the actuator(curvaceous , hydraulic, or electrical).

-Control Signal: The actuator's movement is controlled by signals from a controller(similar as a PLC or microcontroller).

-Mechanical Elements: Factors that transfigure energy into mechanical movement, similar as shafts, comportments, gears, and pistons.

-Feedback Mechanism: Certain systems use sensors(potentiometers, encoders, etc.) to give feedback to the control system for precise control and position.

Types of Actuators and How They Work

Types of Actuators:

- Electric Actuators

- Hydraulic Actuators

- Pneumatic Actuators

- Thermal or Magnetic Actuators

- Mechanical Actuators

How Actuators Work:

1. Electric Actuators

-Working Principle: Electrical energy is used by electric actuators to induce stir. Generally, a motor(a DC or AC motor, stepper motor, or servo motor) does this. A gyration is produced when electricity flows through the motor windings and creates a glamorous field that interacts with the endless attractions.

-Common Uses: Precision motion control operations including robotics, CNC machine tools, and machine systems(e.g., motorized windows, seats) bear electric actuators.

2. Hydraulic Actuators

-Working Principle: With hydraulic actuators, direct or rotary stir is produced by use of a pressurized fluid, generally oil painting. A fluid-filled tube transmits the pressure produced by a hydraulic pump to a piston housed inside a cylinder. The piston is forced to move by the pressured fluid, performing in mechanical stir.

-Common Uses: These actuators are employed in heavy-duty, high-force operations similar aeroplane wharf gear, hydraulic presses, and construction outfit( bulldozers, excavators).

3. Pneumatic Actuators

-Working Principle: Pneumatic actuators use compressed air to serve. Delivered to the chamber, compressed air pushes the piston or diaphragm to induce either direct or rotational stir. The force generated is proportional to the air pressure.

-Common Uses: Common applications for pneumatic actuators include valves, packing, material handling, and factory automation.

4. Thermal or Magnetic Actuators

-Working Principle: These actuators react to variations in magnetic fields or temperature by turning on. Magnetic actuators employ electromagnetic force to create motion, whereas thermal actuators use heat to expand or contract materials (e.g., to create memory alloys) (e.g., solenoids).

-Common Uses: These kinds find use in specific applications, such solenoid valves and thermal switches, which are precise devices utilized in the electronics sector.

5. Mechanical Actuators

-Working Principle: Mechanical actuators translate rotary motion into linear motion and vice versa by using manually driven or operated devices like gears, screws, or cams.

-Common Uses: Utilized in systems that need for straightforward movement, like those that place arms, screw jacks, and antennae.

Applications of Actuators

-Robotics: Robot arms and legs can move precisely thanks to actuators.

-Industrial Automation: For conveying systems, packing, and assembly equipment.

-Automotive Systems: Such as computerized throttle control systems, automated chairs, and electrically adjustable mirrors.

-Aerospace and Defense: For tripods, weapon systems, and flight control systems.

-Consumer Electronics: For gadgets like hard drives (moving read/write heads) and printers (moving print heads).

Differentiation Between Actuators and Sensors

Although they are crucial parts of several systems, actuators and sensors have distinct functions:

1. Sensors:

-Function: Sensors track and measure changes in environmental parameters or physical characteristics including light, stir, pressure, and temperature. The sensor transforms these physical attributes similar as stir, pressure, and temperature—into electrical signals or data that other systems can understand.

-Examples: Pressure sensors, light sensors( photodiodes), stir sensors( accelerometers, gyroscopes), and temperature detectors( RTDs, thermostats).

2. Actuators:

-Function: An actuator is a tool used to restate control orders or electrical impulses into stir or exertion. Actuators are in charge of executing tasks including moving components, opening valves, and altering position in reaction to inputs.

-Examples: Piezoelectric actuators, motors( DC and stepper), servo systems, and solenoids.

Key Differences:

-Purpose: In real time, sensors gather environmental data, and the actuator uses that data to execute a task or take an action.

-Signal Flow: The actuator receives instructions from the system to carry out operations, while the sensor provides data to the system.

-Examples in a System: A thermostat system's temperature sensor measures the interior air temperature and sends that information to the control unit. The actuator, which may be an air conditioner or heating element, is also controlled by the controller using this information. As needed, the temperature is adjusted.

Advantages and Disadvantages of Different Actuators

Since it transforms energy into stir, the actuator is a pivotal element of any system. The benefits and drawbacks of each type of actuator are listed below:

Advantages:

1. Precision and Control: Actuators are perfect for operations that need precise changes because they give exact control over both stir and position.

2. Versatility: Actuators are available in several kinds( similar as electric, hydraulic, and curvaceous) and are used in a multitude of operations, ranging from automotive systems to robotic systems.

3. Automation: Actuators enable robotization in processes and ministry, perfecting effectiveness and reducing the need for homemade intervention.

4. Speed: Short movement and adjustment of several actuators is advantageous for systems that demand short reaction times.

5. Power-to-Weight Ratio: Certain actuators, particularly those that are motorized, have a high power-to-weight rate that makes them useful in operations with constrained space.

Disadvantages:

1. Cost: Actuators can be costly, particularly the more sophisticated varieties like hydraulic or electric ones, which can raise the system's total cost.

2. Complexity: Actuators can complicate system designs and call for complex control systems when they are integrated and controlled.

3. Maintenance: Certain actuators—particularly the pneumatic and hydraulic varieties. They are prone to wear and strain and require routine maintenance.

4. Power Consumption: Particularly electric actuators, are actuators. Its inordinate energy consumption may be problematic for operations that bear low power.

5. Size and Weight: Certain selectors are small and featherlight, but others—particularly those that are hydraulic or curvaceous—can be big and hefty. This makes it possible to use in spaces that are constrained.

Conclusion

An essential component of many systems are actuators. Control and robotization of a wide range of operations, from introductory home appliances to sophisticated artificial machines and sophisticated robots, are made possible by the demand for controlled stir or position through the conversion of different sources of energy as mechanical movement.

How do I choose the right actuator for my application?

Opting the applicable actuator is dependent upon the ensuing rudiments:

-Type of motion required: Linear or rotary.

-Load capacity: The force or torque needed.

-Control signal: Electrical, hydraulic, pneumatic, etc.

-Precision and speed: Precision and haste of the intended movement.

-Environmental conditions: Elements include humidity, temperature, and chemical exposure.

If you have specific requirements or need suggestions, welcome to leave a message at blikai.com! After reading this article, do you know about actuators? Then here is a question. Have you chosen the type of actuator you need?

Related Articles

What Mechanical Actuator is and How it works

Piezoelectric Actuator transducer : Principle & Its Applications

Need Actuator Valves? What You Should Know!