What are Tantalum Capacitors?[All Explained]

What are Tantalum Capacitors?

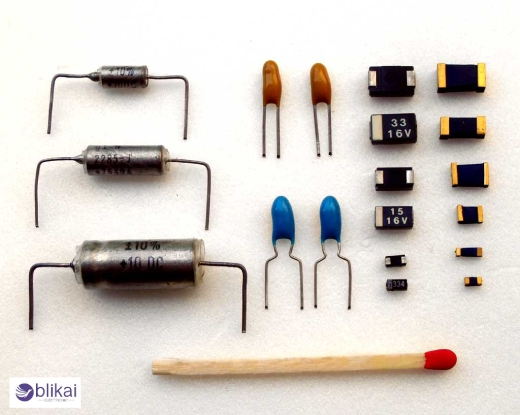

Tantalum capacitors belong to a group of unresistant electronic factors able to store and release electrical energy. Their construction consists of tantalum anodes, a thin tantalum pentoxide dielectric layer, and a conductive cathode. The utmost tantalum anodes are manufactured with sintered tantalum grease paint; they, thus, develop a previous structure, which directly increases capacitance due to the attendant high face area.

Advantages over other capacitor types

Tantalum capacitors have advantages over other capacitor types. They have a higher capacitance-to-volume ratio, allowing the downsizing of electronic equipment. Tantalum capacitors also retain excellent stability over time and temperature fluctuations, which must be channeled into their consistent action. Furthermore, their low equivalent series resistance makes them applicable to high-frequency areas and power supply filtering.

How Tantalum Capacitors Work

Electrical charge storage mechanism

In the case of tantalum capacitors, the charge storage process is relatively special and involves the use of a previous tantalum anode and a thin oxide layer. A similar voltage input leads to the accumulation of electrons on one side of the oxide layer and a consequent positive charge on the opposite side. Therefore, it's the charge separation that permits the capacitor to store electrical energy fluently.

Role of the dielectric layer

The presence of the dielectric layer within the tantalum capacitor is consummate to their functioning. This thin layer, an oxide of tantalum, serves as an insulator between the anode and the cathode. Its dielectric constant and stable parcels allow a tantalum capacitor to store a large quantum of charge in a small volume, exceptionally healthy for miniaturized electronic devices.

Importance of the electrolyte

A tantalum capacitor has an electrolyte as its cathode and makes contact with the dielectric layer. In solid tantalum capacitors, it usually is manganese dioxide: this has a self-healing capability and helps in the repair of the deteriorated dielectrics, leading to paramount improvement in reliability and longevity.

Polarity considerations

A tantalum capacitor is a polarized component with a defined positive and negative orientation. The tantalum anode directly connects to the positive terminal, and the electrolyte cathode directly connects to the negative terminal. Any failure to comply with the polarity will threaten the needs of the capacitor, often leading to destruction. A reverse voltage can break down the oxide layer and lead to catastrophic failure or damage.

Key Functions of Tantalum Capacitors

Coupling and decoupling in circuits

These capacitors are highly useful in coupling and decoupling applications. In coupling, they allow AC signals to pass from one circuit stage to another while blocking DC. In decoupling, tantalum capacitors form a low-impedance path to high-frequency noise to ground, allowing their removal, thus providing the most effective route for noise reduction among various parts of the circuit.

Timing and energy storage

High stability and acceptability make tantalum capacitors an efficient component in timing circuits. Their charging mechanism enables a steady charge in the time domains, following applications for real-time clocks. Since they can offer a potent ratio of capacitance-to-volume for short-term energy storage at various power bursts, they also find their way to short durations of applications requiring quick power bursts.

Noise reduction in audio applications

Tantalum capacitors are predominantly used for noise reduction in audio circuits to improve sound quality. By virtue of their low ESR and high stability, they allow distortion and unwanted interference control and, therefore, deliver cleaner audio signals. This has made them popular in high-fidelity audio equipment and professional sound systems.

Stabilizing voltage in mobile devices

Tantalum capacitors' small size and high availability make them some of the most effective components available for mobile devices. They stabilize voltage in smartphones, tablets, and other handheld electronics by facilitating consistently unearthing powers to several devices therein. They aesthetically charge and discharge at a rapid rate, thus delivering the requirements of changing power supply and drain in the applications.

Selecting the Right Tantalum Capacitor

Capacity and voltage ratings

When considering a tantalum capacitor, the candidates must present suitable capacity and voltage ratings. Capacity is a measure expressed in microfarads (μF) to show how much electrical charge a capacitor can store. High capacities are most suitable in applications where more significant sums of energy are stored. The voltage ratings assert and evaluate the maximum voltage that can be withstood by a capacitor under normal working conditions. To ensure reliability and longevity, it is generally good practice to have a tantalum capacitor whose voltage rating exceeds that of the operating voltage of the circuit itself.

ESR (Equivalent Series Resistance) considerations

ESR is a critical parameter affecting performance. The lower the value of the ESR, the better the high-frequency response and the smaller the power loss. When considering the selection of tantalum capacitors, keep the ESR requirements for your application in mind. These are usually low-ESR tantalum capacitors suitable for high-frequency circuits and power supply decouplings.

Temperature and frequency performance

The stability of tantalum capacitors within wide-temperature ranges allows for their use in various environments. However, one must consider the specific temperature requirements of your application and select a capacitor to operate reliably within that temperature range. Also, take into consideration the frequency performance of the capacitor since certain types may not be able to fulfill requirements for better performance at elevated frequencies.

Installation and Best Practices

Proper handling to avoid damage

Proper handling while working with tantalum capacitors is critical to ensure that they aren't damaged and, therefore, perform at their stylish best. Always observe anti-static preventives similar to wearing an ESD wrist swatch or working on an anti-static mat. These capacitors must be handled with care, not regulated pressure or bending of leads. Also should be kept optionally in their original packaging precaution against moisture and contaminants.

Correct orientation and polarity

Tantalum capacitors are polarized, which means they need to be connected the right way up. There's generally a"+" marking on the positive terminal or a longer lead. Always double-check the opposition before soldering or mounting the capacitor to ensure it'll not be damaged or malfunctioning. Rear opposition can result in unforeseen disastrous failure and sometimes safety issues.

Voltage derating for reliability

The protection and reliability of tantalum capacitors need to operate at a voltage below their rating. The standard practice is to derate capacitors by a factor of 50%, i.e., choose a capacitor rated for double the circuit operating voltage. This alleviates the stress due to voltage spikes and increases the overall life of the capacitor.

Parallel and series configurations

When advanced capacitance or voltage conditions are required, tantalum capacitors can be combined in series or parallel. Connected in parallel, each capacitor adds its capacitance to the total; in series, the attendant voltage standing equals that of the capacitance with the loftiest standing. Care must be taken to ensure that the total voltage drop across all series capacitors is the same, or to connect a balancing resistor is often advised. When parallel-connected, capacitors with identical parameters would be preferable.

Troubleshooting and Maintenance

Common failure modes

While reliable, tantalum capacitors may induce several types of failure. The most common failure mode is the short circuit, resulting from either voltage transients, reverse polarity, or excess current. Another issue is the loss of capacitance over time due to temperature-induced issues. Leakage current and changes in ESR (Equivalent Series Resistance) might also pose problems that could affect circuit performance.

Testing tantalum capacitors

Tantalum capacitors should constantly be tested regularly so they can operate at peak performance. Measure capacitance with a capacitance meter and compare the reading with the rated value. Internal resistance changes can be detected by an ESR meter. To check for dielectric breakdown, raise the applied voltage gradually while monitoring the leakage current. Physical damage or leaking of electrolytes can usually be established during visual inspection.

Replacement guidelines

Always ensure that the voltage rating and capacitance of the capacitor being replaced are the same or higher than that of the original part. The ESR and ripple current ratings should also be considered. It is essential to take care of the polarity while making the replacement; otherwise, it can be catastrophic. Select a replacement of the same case type so the new part will fit into the circuit board that held the defective part.

Extending capacitor lifespan

To maximize the life of tantalum capacitors, run them within their upper limits for voltage and temperature. Adequate circuit protection should be applied to avoid voltage transients and reverse polarity. In high-reliability applications, consider derating to 20-30% of the rated value. Ensure the capacitors are in a heat-dissipative environment and not subjected to excessive vibration or mechanical shock.

Conclusion

Tantalum capacitors play a critical role in certain electronics today due to their uniquely favorable attributes of size, performance, and reliability. We profiled in an introductory manner how these components operate and their broad diversity in types and applications in electronic circuits. It's essential to know the criteria for selection, the techniques for installation, and the care of tantalum capacitors to derive all the benefits they can offer.

Related Articles

What is a Bypass Capacitor & Why Do You Need One?

Installing a Dual Run Capacitor: What You Need to Know

What is a Ceramic Capacitor and How Does it Work?

What is an Audio Capacitor and Why Does it Matter?

What is a C65R Capacitor? A Beginner's Guide

How to Test an Electrolytic Capacitor

CBB65 Capacitors: Key Features, Applications & Advantages

CBB60 Capacitor: Characteristics, Applications & Advantages

Capacitor Symbol: What Does It Really Mean?

What is Tantalum Capacitor: Design, Construction and Applications

Capacitor Tester: Types, Applications & Advantages

How to Test a Capacitor: Simple Steps and Tools

How to Test a Capacitor with a Multimeter [Guide]

Series Capacitor Calculator: Full Explained