What Does a Tantalum Capacitor Do

Understanding Tantalum Capacitors

Tantalum capacitors are crucial electronic elements that accumulate and discharge electrical energy. These passive components consist of a tantalum anode, a dielectric layer composed of tantalum pentoxide, and a conductive cathode. Their primary function is to maintain a stable voltage supply in the electronic circuit that releases electrical energy if it is stored and when needed. This capacity makes it essential to filter the power supply in various electronic devices, deepening and smoothing them.

Unique properties of tantalum

Tantalum capacitors have primary materials and many unique properties that make them ideal for this application. Its high dielectric constant allows for more tuberculosis in a small package than other materials. Tantalum also exhibits excellent stability in a wide temperature range, ensuring frequent performance in diverse operating conditions. Additionally, its self-healing properties contribute to the long-term reliability of the tantalum capacitors, as minor defects in the dielectric layer can often repair themselves during the operation.

Comparison with other capacitor types

Tantalum capacitors offer various advantages over other capacitor varieties. In contrast to electrolytic capacitors, they possess a markedly low equivalent series resistance (ESR), which leads to improved high-frequency efficiency and reduced power loss. Tantalum capacitors also assert a more excellent support-to-volume ratio than ceramic capacitors, making them suitable for space-related applications. Nonetheless, they tend to be pricier than aluminum electrolytic capacitors and possess lower voltage ratings compared to certain other varieties.

Key Components of a Tantalum Capacitor

Tantalum anode

A tantalum capacitor is the origin of a tantalum anode. It has a highly porous structure made of sinful tantalum powder. This permeable nature enhances the surface area, which allows for high timber in a small package. Tantalum content is chosen for its excellent stability and the ability to create a thin, similar oxide layer.

Dielectric layer

The dielectric layer in a tantalum capacitor is a thin oxide film formed through an electrochemical process on the surface of the tantalum anode called anodization. The thickness of this layer determines the capacitor's voltage rating, while its thinness contributes to the high-spoiled values obtained in the tantalum capacitor.

Cathode material

The cathode in a tantalum capacitor is usually made of manganese dioxide or a conductive polymer. This material fills the pores of the tantalum anode, acting as the capacitor's negative terminal. The choice of cathode material affects the capacitor's electrical characteristics, including its ESR (equivalent chain resistance) and frequency reaction.

External casing

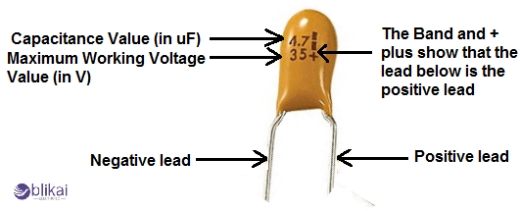

The outer cover protects the internal components and provides a means to connect the capacitor to a circuit. It is usually made of epoxy resin or metal with a lead or surface-mount pad for electrical connections. The casing also often includes markings for identification, polarity, and ratings.

How Tantalum Capacitors Work

Charge storage mechanism

Tantalum capacitors stool the electric charge through a unique process, which includes a dielectric layer of tantalum pentoxide. When a voltage is applied, the tantalum anode is positively charged, making electrons draw on its surface. These electrons then get stuck in the dielectric layer, forming a stored charge. The manganese dioxide acts as a return tract for the cathode electric current.

Voltage handling capabilities

Tantalum capacitors excel in handling high voltage due to their strong construction. The tantalum pentoxide dielectric layer can withstand significant electric fields, allowing these capacitors to work at higher voltage than many other types. This capability makes them ideal for applications requiring stable performance under varying voltage conditions.

Current flow process

When a tantalum capacitor is attached to a circuit, current flows from electrons to the anode from the cathode. During charging, electrons accumulate on the dielectric layer, forming an electric field. When discharging, the stored electrons are flown back through the circuit, and the stored energy is released. This process occurs rapidly, allowing tantalum capacitors to respond quickly to changes in voltage and current demands.

Advantages of Using Tantalum Capacitors

High capacitance in small sizes

Tantalum capacitors are famous for their ability to pack a significant amount of tuberculosis in a compact package. This high support-to-volume ratio makes them ideal for space-related applications in modern electronics. The unique properties of tantalum allow for the manufacture of a skinny dielectric layer, resulting in higher tidal values than other types of capacitors of the same size.

Excellent stability over time

A remarkable feature of tantalum capacitors is their exceptional stability. In contrast to various other capacitor types, tantalum capacitors retain their electrical properties for a long duration, guaranteeing consistent performance throughout the device's lifespan. This stability is crucial in fields where long-term dependability is vital, such as aerospace and medical devices.

Wide operating temperature range

Tantalum capacitors excel in environments with extreme temperature fluctuations. They can effectively work in a broader temperature spectrum, usually from -55 ° C to +125 ° C. This detailed operating range suits them for use in a rigid environment, including motor vehicle applications and industrial settings where temperature control can be challenging.

Low equivalent series resistance (ESR)

The low ESR of tantalum capacitors is a significant advantage for many electronic circuits. A low ESR resulted in improved power shortage and improved efficiency, causing tantalum capacitors, which are especially useful in power supply circuits and existing applications. This characteristic also contributes to better noise filtering and smoother voltage regulation.

Long lifespan

Tantalum capacitors are known for their extraordinary longevity. When adequately used within their specified ratings, these capacitors can exclude several other components in a circuit. Their long lifetime is attributed to the stability of tantalum oxide and the strong construction of the capacitor. This durability makes them an excellent choice for applications where frequent maintenance or replacement is impractical or expensive.

Common Applications of Tantalum Capacitors

Consumer electronics

Tantalum capacitors are essential in the electronics industry because of their exceptional performance and small size. These capacitors are generally set up in smartphones, tablets, laptops, and gaming devices. Their capability to store and release energy makes them perfect for enhancing colorful functions in these devices, including touchscreen, processor, and memory module. Additionally, tantalum capacitors help in noise and signal filtering, which ensures the smooth operation of audio and video components in high-end sound systems and televisions.

Automotive systems

The automotive sector relies significantly on tantalum capacitors due to their responsibility and consistency in harsh surroundings. These capacitors are pivotal rudiments in machine control units, airbags, and advanced driver backing technologies(ADAS). They also have an essential function in the infotainment system, which guarantees the nonstop functioning of navigation, audio, and connectivity features. With the rising fashionability of electric vehicles, tantalum capacitors are snappily being employed in battery operation systems and power inverters, enhancing both effectiveness and performance.

Aerospace and military equipment

Tantalum capacitors hold significant significance in service and aerospace operations because of their precious characteristics and capability to endure extreme temperatures. They're employed in satellite communication systems, radar devices, and avionics technology. In military tackle, this capacitor companion is essential for systems, communication outfits, and electronic war outfits. Their long continuance and trustability make them ideal for use in charge-lovemaking systems where failure isn't an option.

Medical devices

In healthcare, tantalum capacitors are critical components in a range of life-saving equipment. They are utilized in implantable medical devices like pacemakers and defibrillators, where their compact size and extended stability are crucial. Tantalum capacitors are used in medical equipment like MRI machines and CT scanners, contributing to precise and dependable performance. Their low leakage current and high reliability make them suitable for use in portable medical devices and monitoring devices, which contributes to the patient's care and mobility.

Considerations When Using Tantalum Capacitors

Voltage derating

Voltage derivatives are essential when using tantalum capacitors. To ensure reliability and longevity, these capacitors are recommended to operate much less than their rated voltage. Typically, a derivative factor of 50–60% is applied, which means a 10V rated capacitor should be used in circuits, with the operating voltage not exceeding 5–6V. This practice helps prevent voltage spikes and reduces the risk of capacitor failure or even frightening breakdowns.

Polarity awareness

Tantalum capacitors are polarized components, which means they have a specific positive and negative orientation. Installing them incorrectly can cause immediate failure or explosion. Always check the polarity marks on the capacitor and ensure proper orientation in the circuit. In designs where reverse voltage might occur, consider using non-polarized alternatives or implementing protective circuitry.

Cost factors

While tantalum capacitors provide excellent performance, they are more expensive than other capacitor types. This premium is due to the lack of tantalum and complex manufacturing processes. When designing circuits, balance the need for high performance against budget constraints. In some cases, alternative capacitor types provide adequate performance at a lower cost.

Environmental concerns

The production and disposal of tantalum capacitors enhance environmental and moral concerns. Tantalum mining is associated with conflict in some areas, which inspires the need for responsible sourcing. Additionally, these capacitors contain materials that can be harmful if not adequately dealt with. When selecting components, consider the manufacturers who prefer moral sources and provide guidance on proper disposal or recycling.

Conclusion

Tantalum capacitors play an essential role in modern electronics, providing unique benefits that make them indispensable in various applications. From their compact sizes and large -cordial size and their excellent stability and reliability, these components have proved their qualifications in industries from consumer electronics to aerospace technology. Whether you are an engineer, hobbyist, or only eager to electronics, understanding the functions and benefits of tantalum capacitors can provide valuable insight into the complex world of electronic components.

Related Articles

What is a Bypass Capacitor & Why Do You Need One?

Installing a Dual Run Capacitor: What You Need to Know

What is a Ceramic Capacitor and How Does it Work?

What is an Audio Capacitor and Why Does it Matter?

How to Test an Electrolytic Capacitor

CBB65 Capacitors: Key Features, Applications & Advantages

CBB60 Capacitor: Characteristics, Applications & Advantages

Capacitor Symbol: What Does It Really Mean?

What is Tantalum Capacitor: Design, Construction and Applications

Capacitor Tester: Types, Applications & Advantages

How to Test a Capacitor: Simple Steps and Tools

How to Test a Capacitor with a Multimeter [Guide]

Series Capacitor Calculator: Full Explained

Capacitors in Series Calculator: Everything Explained