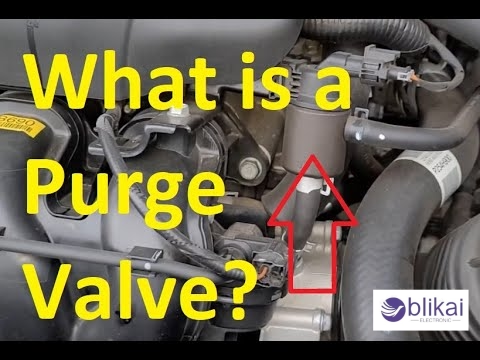

What Is a Purge Valve & How Does It Work?

Understanding the Purge Valve

In other words, it can be called the barrel purge valve or an EVAP purge valve is an intertwined and integral element of a vehicle's evaporative emigration control( EVAP) system. The primary function of this valve is to allow a controlled inflow of fuel vapors from the watercolor barrel into the machine. This is essential for controlling poisonous emigrations and enhancing fuel frugality by snooping with vapor escaping into the atmosphere.

Role in the emission control system

As such, the purge valve is part of the EVAP system, with roles being of utmost importance. It helps with the release of fuel vapor from the charcoal canister when optimum conditions exist in the engine intake system. This then gets combusted in the combustion chamber. Once combustion occurs, emissions are reduced, and no fuel is wasted. It will help keep the pressure in the fuel system and aid in the efficient running of the EVAP system. In this way, it manages vapor flow, allowing the vehicle to work optimally and stay within environmental compliance.

Components of a Purge Valve

Solenoid

The solenoid is the central part of the purge valve being a basic electromagnetic switch. It comprises a wire coil wrapped in a core of metal. Passage of an electrical current through the coil would induce a magnetic field capable of moving the metal core-or it does so, and this opens and closes the valve.

Valve mechanism

The valve mechanism itself is connected directly to the solenoid. Typically, this consists of a spring-loaded plunger or diaphragm that moves in response to the action of the solenoid. The valve allows vapor to either flow from the fuel or not, depending on whether or not the system is capturing or venting volatile emissions.

Electrical connections

Wires are also important for the purging valve's operation. ECM commands for opening or closing the purge valve are based on certain engine conditions or driving parameters on such connections.

Charcoal canister interface

In fact, the purge valve interfaces with the charcoal canister as part of the vehicle's evaporative emission control system. This connection generally consists of one or more hoses linking the valve to the canister. If the valve opens, vapor flows from the charcoal canister to the engine.

How a Purge Valve Operates

Closed position function

While in the closed position, the purge valve serves as an airtight seal that does not allow fuel vapors to escape from within the charcoal canister. This containing of vapors is quite important to the emission control system in order to keep it from polluting the air. The valve will be practically permanently closed in order to contain those harmful vapors from being emitted out into the atmosphere while driving.

Open position function

When the engine reaches the right temperature and driving conditions, vapor will flow from the charcoal canister into the engine's intake manifold through an opening in the purge valve. The opening is generally dependent on vacuum pressure or an electrical signal from the engine control module.

Purge cycle explanation

The purge cycle happens when the engine generates a negative pressure sufficient to enable vapors to be trapped underneath its surface before guiding the vapors through the purge valve and into the manifold. Due to the combustion, the vapors are subsequently incorporated with the reintroduction of fuel with fresh air to be consumed in the combustion process.

Interaction with the engine control module

The ECM plays a crucial role in operating the purge valve. It monitors the engine temperature, load, and speed and determines the best timing for the purge cycle. It uses the relevant electronic inputs and outputs signal to open the valve and subsequently closes it. The purging is ensured to run efficiently, resulting in no engine performance or emissions control compromise. All this interaction allows for precise control of the offending emissions system, promoting better fuel economy and reduced environmental impact.

Advantages of a Properly Functioning Purge Valve

Improved fuel efficiency

A working purge valve is essential for gaining better fuel economy out of your vehicle. It regulates the flow of fuel vapors from the charcoal canister to the engine; therefore, it controls what fuel vapors will expend in the combustion process and what will be wasted. It contributes to the improvement of fuel economy because fuel is being oversupplied with fuel vapors.

Reduced emissions

One benefit of well-maintained purge valves is the integral part they play in pollution control. At the same time, they curb the emissions attributable to the burning of vapors as they pass into the atmosphere, and therefore, your car meets emissions standards. Thus the burning of emission-restricted fuels causes less harmful pollutants to enter the atmosphere, hence accommodating easy passage for the vehicle through emissions tests.

Enhanced engine performance

A workable purge valve supports smoother engine operation. Though controlling fuel-vapor flow into the engine at a suitable time, it allows for the ideal air-fuel mixture to enhance combustion. This results in improved engine performance, efficient running, smooth acceleration, and less likelihood of engine misfire or hesitation while driving.

Compliance with environmental regulations

However, over the years, environmental regulations have become ever-stricter: the purge valve must function effectively to meet requirements. It makes sure that your engine is running with concerns of emissions, saving you from money-draining fines or penalties. Above all, it would be a great help against air pollution and climatological change.

Signs of a Faulty Purge Valve

Check engine light activation.

One of the first warning signs of a faulty purge valve is the illumination of the check engine light. This signal may be triggered by varying problems, including the purge valve. When the engine control unit identifies any abnormal readings or performance within the evaporative emissions system, it activates the check engine light exclusively to alert the driver.

Rough idling or stalling

Another important reason is that it causes the engine to stumble if not stall. It occurs due to leakage of rich combustible vapors into the intake manifold, as the valve might be stuck in the open position. If this happens, the mixture of air and fuel will not combust appropriately and idle rough or stuttering. In more extreme cases, the engine could stall entirely, especially if the vehicle has come to an idle or is in low gear.

Decreased fuel economy

Then again, your drop in fuel economy could be related to a failing purge valve. A malfunctioning control valve can allow too much vapor to enter the combustion chamber and provide a vibrant fuel-to-air mixture. This not only leads to a loss of miles per gallon but also places unwanted stress on the engine.

Failed emissions test

Failure of your vehicle emissions test might be attributed to a malfunctioning purge valve. The purge valve performs a central function in the evaporative emissions control system, which relates to staving off the release of fuel vapor in the atmosphere. In case the valve was to fail, it might result in heightened emissions, leading to your car failing to meet the standards set for permissible pollution values during testing.

Unusual fuel odors

When you smell gasoline wafting around your vehicle, have it repaired immediately. Or else, when it's parked or idling, this could mean the purge valve has failed. Being stuck in the open position can cause lots of fuel vapor to escape the fuel system and a lot of smells. This doesn't only mean that the purge valve has a problem but also that it is a significant fire hazard because these vapors are flammable.

Maintenance and Replacement

Regular inspection intervals

Being stuck in the open position can cause lots of fuel vapor to escape the fuel system and a lot of smells. This doesn't only mean that the purge valve has a problem but also that it is a significant fire hazard because these vapors are flammable.

Cleaning procedures

If you see a bit of build-up or deposits on the purge valve, cleaning can often restore this to an operative condition. Carburetor cleaner or other specifically designed cleaning agents for the EVAP system will remove any carbon figure-up or pollutants that inhibit operation. Apply it directly, let it sit for many twinkles, and wipe clean with a clean cloth.

When to replace the purge valve

Replacement is necessary when the purge valve shows signs of extreme wear, crack, or malfunctions. If you get habitual check machine lights related to the EVAP system. The utmost purified faucets last 50,000 to 80,000 long hauls, depending on the condition of driving and conservation habits.

Related Articles

DC Machine : Construction & Its Principle

What a Human Machine Interface system is and How it works

Human-Machine Interface(HMI) Technology [Explained]

0603USB-251MLC TRI Component: Features, Applications, and Datasheet

TCA9535PWR Component: Applications, Features and Datasheet

Exploring Electronic Components - Their Varieties, Roles, and Future Directions

Multimeter Not Reading DC Voltage: How to Fix it?

Polyester vs Polypropylene Capacitors: Explained

Unveiling Polypropylene Capacitors: Principles, Applications, and Future Trends

Motherboard: The Core of Computer Hardware

The Automotive PCB Market Seizes Fresh Opportunities

The Interconnection Between Semiconductors and Cybersecurity

Exploring Varied Types of Inverters