What Mechanical Actuator is and How it works

In electrical machines, an actuator is a crucial component utilized to move and control a system or device. It employs an energy source along with a control device, typically a valve. When the control device receives a control signal, the actuator swiftly responds by converting the energy source into mechanical motion. There are various types of actuators, including soft, hydraulic, pneumatic, electric, thermal/magnetic, and mechanical actuators. This article focuses on one specific type: mechanical actuators, covering their operation and applications.

What is a Mechanical Actuator?

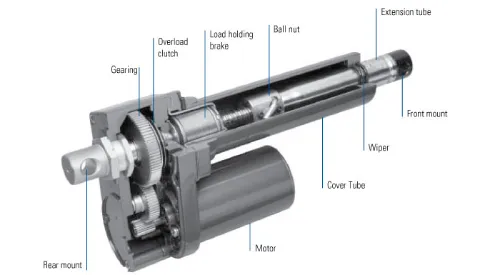

A mechanical actuator is a device that employs a power source to achieve physical movement. These actuators are vital and can be found in nearly every automated machine. The power sources used in mechanical actuators include electric current, pneumatic, and hydraulic systems, which can be manually operated or automated. The primary function of a mechanical actuator is to convert rotary motion into linear motion using gearing at different speeds. Mechanical actuators are classified into types such as lead screws, ball screws, rack and pinion, and belt-driven actuators. The diagram below illustrates a mechanical actuator.

Mechanical Actuator Working Principle

The working principle of a mechanical actuator involves converting rotary motion into linear motion to perform movement. The operation of a mechanical actuator primarily relies on combinations of structural components such as rails and gears, or chains and pulleys.

Mechanical Actuator Design

A mechanical actuator is designed using various components, with the key activating elements being the motor, gearing, screw assembly, and extension tube. These actuators typically function by transforming rotary motion into linear motion.

Motor

The motor used in this actuator is a DC motor, which generates all the actuator’s power.

Gearing

Gearing, made of either plastic or steel, is designed to modify the speed relationship between the driving mechanism and the driven parts. It connects directly to a power source such as the motor.

Screw

This actuator operates using a screw mechanism. Turning the nut of the actuator causes the screw shaft to move in a linear direction.

Extension Tube

The extension tube, also known as the inner tube, is typically made of stainless steel or aluminum. It connects to the threaded drive nut and extends or retracts as the nut turns along the rotary spindle.

When the actuator’s motor is powered, it rotates the gearing, which multiplies the torque and reduces the motor speed. This gearing rotation drives the screw, and the nut on the screw is connected to the extension tube, moving it in or out depending on the screw's direction.

Many actuators feature a wrap spring brake that holds the load when the motor is not running. This brake maintains the load in any direction, whether pushing or pulling, without requiring power. Actuators may use lead screws or ball screws.

Mechanical Actuator Types

There are three types of mechanical actuators available in the market: pneumatic or air pressure, hydraulic or fluid pressure, and electric actuators.

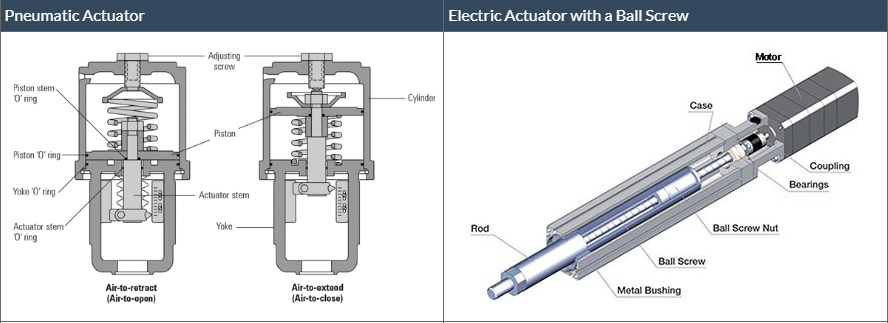

Pneumatic Actuators

A pneumatic actuator uses pressurized gas or compressed air to create controlled movement. These actuators are versatile and can be adapted for use in various projects. The main advantage of this actuator is its simplicity and safety compared to both hydraulic and electric actuators, as it does not require electricity or ignition to operate. However, a significant drawback is that a compressor must run continuously to maintain working pressure, whether the device is in use or not.

Hydraulic Actuator

A hydraulic mechanical actuator uses liquid pressure to generate mechanical movement. These actuators are primarily used when a substantial amount of power is necessary for a system or machine to function. They are commonly found in heavy machinery, where hydraulic power is controlled by the amount of liquid within a cylinder. Increasing the fluid creates pressure, while decreasing the fluid reduces pressure. Although these actuators are very effective when high-powered energy is needed, they are complex and require highly trained mechanics to operate and maintain. For more information about Hydraulic Actuators.

Electric Actuator

An electric actuator converts energy from an electrical power source into mechanical motion. It is commonly used for valve operation, food and beverage manufacturing, material handling, and cutting equipment. Generally, electric actuators are easier to maintain than hydraulic actuators and offer a high degree of precision.

The main drawbacks of electric actuators include their unsuitability for all environments and the need for controls to manage overheating tendencies. They do not have a reliable position in the event of power loss and have a higher average failure rate compared to pneumatic actuators.

Here are 15 factors to consider when choosing between pneumatic actuators or electric actuators.

| Pneumatic Actuators | Electric Actuators | |

| Design | Simple | Complex |

| Force | Depends on air pressure | Depends on screw pitch/lead |

| Speed | High | Low |

| Accuracy | Low | High |

| Repeatability | Low | High |

| Motion Control Capability | Low | High |

| Efficiency | Low | High |

| Cost | Lower initial cost | Lower total cost of ownership |

| Data Collection | Still developing | Highly developed |

| Environment | Harsh, hazardous | Refer to IP rating |

| Temperature | Higher ambient temperature | Lower ambient temperature |

| Noise | High | Low |

| Maintenance | High | Minimal |

| Life | Estimated | Calculated |

| Ideal Application | End-to-end postioning | Multi-point positioning |

Design

Pneumatic actuators have a simpler design compared to electric actuators, which incorporate more complex components like ball screws and electric motors.

The straightforward design of pneumatic actuators also lends itself to greater compactness compared to electric actuators. However, when considering all the additional components required to maintain air pressure, the overall space occupied by pneumatic actuators can actually be larger. More details on this will follow.

Here we compare a standard pneumatic actuator with an electric cylinder featuring a ball screw.

Advantages and Disadvantages

Advantages of mechanical actuators include the following:

- These actuators are very easy to use.

- The precision level is high.

- These are cost-effective.

- These are versatile and customizable.

- These are very secure.

- Their performance is long-lasting.

- They offer extended reliability.

- Easy setup and installation.

- Motion control is more accurate.

- Less noise.

- Less maintenance.

- Energy consumption is less.

- No leaks and a complete range of sizes, options, and configurations.

Disadvantages of mechanical actuators include the following:

- Compared to pneumatic, the electrical actuator is less cost-effective.

- Severe working environment.

- If power is lost, there is no fail-safe position.

- In a pneumatic actuator, the compressor should run constantly.

- Hydraulic actuators have an unstable nature.

- Hydraulic actuators need extremely trained mechanics.

- These are very sensitive to vibration.

Applications

The applications of mechanical actuators include the following:

- Mechanical actuators convert rotational movement into linear movement.

- They are suitable for applications requiring linear movements such as elevation, translation, and linear positioning.

- These actuators function by transforming one type of motion into another using pulleys, gears, chains, etc.

- They convert electrical input signals into mechanical excitation forces. They are used in conjunction with separate radiators in distributed mode loudspeakers and for active control applications in vibration and noise cancellation.

- These devices offer limited and controlled movements, operated manually, electrically, or with various fluids such as hydraulic or pneumatic systems.

In summary, mechanical actuators operate by converting input power into motion, differing in internal mechanisms based on the desired output direction and the specific power source used. The output motion direction can be either rotary or linear. Generally robust, these actuators excel in high-torque applications compared to electromagnetic types.

Related Articles

What Arduino Nano Board is and how it works