What are Flat Flex Ribbon Jumpers(FFRJs)? All Explained

What are Flat Flex Ribbon Jumpers(FFRJs)?

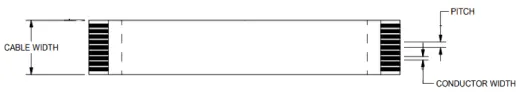

Specialized cables called flat ribbon jumpers (FFRJ) are used to link electrical parts in gadgets where flexibility and space are crucial. Its structure is flat and resembles a ribbon. It differs from traditional round wires in this way.

Components and Structure

Conductors:

Typically, a thin copper strip serves as the conductor in a Flat Flex Ribbon jumper. By doing this, the associated components' electrical conductivity is guaranteed. The precise application and design specifications may affect the quantity and width of conductors.

Insulation Material:

There are several uses for the insulating material that surrounds the conductor. In order to avoid short circuits, it offers electrical insulation. It has thermal stability to tolerate a broad operating temperature range and mechanical protection to survive bending and folding. Because of polyimide's superior resistance to heat and chemicals, it is frequently used under the trade name Kapton.

Connectors:

Ribbon jumpers that are flexible and flat typically include connectors on both ends. for the purpose of making connections to electrical circuit boards or electronic components simple and safe. The kind and configuration of these connectors can differ. offers options for through-hole or surface mount soldering. Depending on certain usage circumstances.

Types of Flat Flex Ribbon Jumpers

Single-sided vs. Double-sided

- Conductors are present on just one side of a single-sided FFRJ. Because of this, it can be used in applications requiring simpler connections. and sending signals only in one direction is adequate. When there is a shortage of space and minimal weight requirements, they are frequently utilized.

- Conductors are present on both sides of the strip in double-sided FFRJs. These jumpers can be utilized in applications that call for more intricate routing since they are more adaptable. or when a restricted area needs to be traversed by the signal path.

Shielded vs. Unshielded

- FFRJs with insulation provide an extra coating of defense. It encircles the conductor and is usually composed of metal. This shielding is appropriate for applications where signal integrity is crucial or electromagnetic interference is a concern since it lessens both electromagnetic interference (EMI) and radio frequency interference (RFI).

- Unshielded FFRJs lack this additional shielding layer, offering a more lightweight and flexible option. They are often chosen for applications where EMI/RFI protection is not a significant concern or where cost and weight savings are priorities.

Customizable Options

Flat Flex Ribbon Jumpers can be customized to meet specific design requirements. Customization options may include:

- - Length and Width: Modifying the ribbon's size to meet certain electrical device space requirements.

- - Connector Types: Choosing a connection that fits onto the circuit board or another component's matching connectors.

- - Specialized Materials: Choosing insulating materials with certain qualities in mind, such more flexibility. superior chemical resistance or enhanced heat resistance.

Advantages

Flexibility and Space-saving

The FFRJ's flat, strip-like construction is one of its primary advantages. This facilitates easy bending, folding, and maneuvering in confined areas. This adaptability enables electronic gadgets to use their available space more effectively. lowers the weight and size of the system as a whole. By minimizing the footprint of interconnects, FFRJs contribute to the compact design of modern electronics without compromising functionality.

High Reliability and Durability

FFRJs are designed to withstand repeated bending and flexing without compromising electrical performance or mechanical integrity. Utilizing sturdy components for conductors and insulation, such as premium copper and polyimide. Long-term use reliability is ensured by doing this. Because of its longevity, FFRJ is perfect for applications like portable gadgets where continuous movement or vibration is expected. aeronautical systems and automobile electronics.

Cost-effectiveness

In addition to their physical advantages, FFRJs offer cost benefits in both manufacturing and assembly. Their flat design simplifies automated assembly processes, reducing production time and labor costs. By decreasing material waste and enhancing supply chain logistics performance, the adoption of standardized parts and materials also raises cost effectiveness.

Ease of Installation and Maintenance

The FFRJ is made to be installed quickly. Its connectors make it possible to swiftly and safely connect it to a circuit board or other electronic component. Their flexible nature allows for straightforward routing and positioning during assembly, reducing the risk of installation errors and ensuring consistent electrical connections. Maintenance of FFRJs is also simplified due to their robust construction and minimal susceptibility to wear and tear, requiring less frequent replacement and servicing.

Common Applications

Consumer Electronics

In computers and laptops, FFRJs are employed for connecting components such as hard drives, optical drives, and display panels. Their flat, flexible structure allows them to be routed efficiently within the compact confines of these devices, optimizing space and ensuring reliable data transmission.

Mobile devices benefit from FFRJs in applications ranging from internal circuitry connections to display and camera modules. For devices like smartphones, tablets, and wearables where space is limited and durability is crucial, its lightweight and flexible design is perfect.

Automotive Industry

FFRJs are crucial for connecting electronic systems and parts in the automotive industry. utilized in systems like infotainment systems seen in cars. Show the Engine Control Unit (ECU) and Sensors on the dashboard Because of its resistance to vibration and temperature changes, FFRJ is perfect for the demanding conditions seen in vehicle electronics.

Medical Devices

FFRJs are essential components in medical devices where reliability and precision are paramount. They are used in equipment such as diagnostic devices, patient monitoring systems, and surgical instruments. The flexibility and durability of FFRJs ensure consistent performance in critical medical applications, contributing to patient safety and device efficiency.

Industrial Machinery

FFRJs are used to connect actuators, sensors, control panels, and other electronic parts in industrial machinery. the capacity to endure challenging operating circumstances, such as exposure to dust, humidity, and temperature fluctuations. It is therefore perfect for factory machines, robots, and industrial automation. FFRJs' reliability helps maintain uninterrupted operation and enhances overall system performance in industrial environments.

How to Select the Right Flat Flex Ribbon Jumper

Key Factors to Consider

- Electrical Requirements:

Assess the electrical properties, including voltage ratings, that are necessary for your application first. criteria for signal integrity and matching of impedance The FFRJ's conductor count and kind must match the electrical specifications of the circuit to which it is connected.

- Environmental Conditions:

Examine the temperature range and other environmental elements to which the FFRJ will be exposed. Humidity level and chemical or pollutant exposure For jumper insulation and protection, choose materials that are resistant to deterioration in these circumstances. This guarantees enduring dependability.

- Mechanical Specifications:

Consider the mechanical aspects such as the required flexibility, bending radius, and durability. Depending on the application, you may need FFRJs that can withstand frequent flexing or harsh mechanical stress without compromising electrical performance.

Manufacturer Considerations

- Quality Standards:

Choose FFRJs manufactured by reputable suppliers who adhere to industry standards for quality and reliability. Look for certifications such as ISO standards or specific industry certifications relevant to your application (e.g., automotive or medical standards). Quality assurance processes ensure consistency and reliability in FFRJ production.

- Customization Capabilities:

Opt for a manufacturer that offers customization options to tailor the FFRJ to your specific needs. This includes selecting the length, width, and type of connectors suitable for your application. Customized FFRJs that satisfy specific design requirements can be supplied by manufacturers with a wide range of customization options. fit in with your electronic systems without any trouble.

Installation and Maintenance Tips

In order to maximize the performance and durability of flat ribbon jumpers (FFRJ) in electronic applications, proper installation and maintenance procedures are essential.

Proper Handling and Storage

It's crucial to handle FFRJs carefully to prevent harming insulation and delicate conductors. FFRJs should be kept in a dry, clean atmosphere. Avoid exposure to high temperatures, high humidity, and direct sunshine. Steer clear of abrupt bends or wrinkles that can weaken the jumper or interfere with its electrical functionality. Properly coiling or looping FFRJs during storage can help prevent tangling and reduce strain on the conductors.

Installation Guidelines

During installation, follow these guidelines to ensure optimal performance and reliability of FFRJs:

- - Avoiding Bends and Twists:

FFRJs should be routed with gentle curves and bends that meet the manufacturer's recommended bending radius. Sharp bends or twists can stress the conductors and insulation, potentially leading to signal degradation or physical damage. Use cable management techniques to secure and guide FFRJs along their intended path without excessive strain.

- - Ensuring Secure Connections:

When connecting FFRJs to circuit boards or other components, ensure that connectors are securely attached and aligned correctly. Proper soldering techniques or connector crimping should be employed to establish reliable electrical connections. Inspect connections visually to verify proper alignment and contact.

Maintenance Practices

Regular maintenance helps prolong the lifespan and reliability of FFRJs in electronic systems:

- - Regular Inspections:

Check the FFRJ on a regular basis for indications of wear, corrosion, or degradation. Look for any obvious breaks, cracks, or discoloration on the connectors or insulation. Conduct electrical testing as required to ensure signal integrity and continuity.

- - Cleaning and Care:

To keep your FFRJ clean, simply wipe away any dust or grime with a gentle, dry cloth. Steer clear of strong chemicals or solvents that could harm conductors or insulation. If cleaning is required, apply a solution of mild detergent. Additionally, before reinstalling, make sure everything is totally dry.

Conclusion

In conclusion, the development of flexible ribbon jumpers is crucial to the progress of electrical technology. They make it easier and trouble-free to integrate components into industrial machines, automobile systems, medical devices, and electrical gadgets. Their ongoing advancement and use highlight how crucial they are as an essential part of the electronics sector. promoting creativity and making it possible to produce cutting-edge electronic goods for a variety of uses.

Related Articles

What is Firewire Cables? All Explained

Modular Cables: Types, Advantages & Applications

D-Sub Cables: Types, Applications & Advantages

Capacitor vs Resistor: What's the Differences?

ATMega328P Microcontroller: A Powerful Microcontroller

2N3904 vs 2N2222:What You Need to know

Cross Sectional Area of Wire: Everything You Need to Know

How does the Oscilloscope's X-Y Display Work ?

Exploring Varied Types of Inverters

What are Proximity Sensors ?