What is an Electronic Fuse? All You Need to Know

Understanding Electronic Fuses

An electronic fuse, an e-fuse, is an advanced circuit protection device that shields electronic systems from overcurrents and overvoltage conditions. Unlike traditional fuses that can only be used once and are then consumed, electronic fuses can be reset and reused multiple times. In short, it acts as an eyesight to control current flow and voltage levels, thus interrupting the circuit in a fast case whenever a dangerous condition is found.

Key Components of an Electronic Fuse

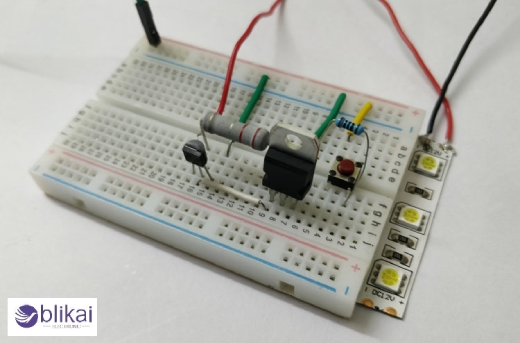

- Current sensing element: Monitors the current flowing through the circuit

- Control circuit: Processes input from the sensing element and triggers protective action

- Switching element: Usually a MOSFET or transistor that interrupts the circuit when activated

- Voltage regulator: Maintains stable voltage for the control circuit

- Reset mechanism: Allows the fuse to be reactivated after a fault condition is cleared

How Electronic Fuses Differ from Traditional Fuses

Electronic fuses offer significant advantages over traditional fuses:

- Reusability: Can be reset multiple times, unlike conventional fuses, which require replacement after each use

- Precision: Provide more accurate and consistent protection due to their electronic nature

- Programmability: Many e-fuses can be programmed for specific current and voltage thresholds

- Speed: React faster to fault conditions, potentially preventing damage to sensitive components

- Diagnostic capabilities: Some advanced e-fuses can provide information about fault events

Types of Electronic Fuses

Resettable fuses

Resettable fuses, or polymeric positive temperature coefficient (PPTC) devices, are a very common alternative to electronic fuses. They self-reset after clearing the fault condition, thus avoiding replacement. If overcurrent is present, the PPTC material heats up as it swells, and the resistance significantly increases, cutting down the current. When the electrical fault is cleared, the device cools down and returns to a low-resistance state.

Programmable fuses

Programmable fuses enhance circuit protection by allowing users to fine-tune their trip characteristics. These programmable fuses can respond to various current or voltage thresholds; some are responsive to ambient temperature, depending on user requirements. This flexibility allows them to offer ideal protection of complex systems where the requirement for protection may vary with operating conditions.

Smart fuses

Innovative fuses offer an added dimension to fuse characteristics. For instance, they integrate monitoring and communication features. They can provide real-time current flow, temperature, or fault condition information. Some innovative fuses also have remote control features, allowing users to reset or adjust the fuse remotely. This intelligence enables proactive maintenance and improved system reliability.

Solid-state fuses

Solid-state fuses use semiconductor technology for fast, clean, and accurate protection. They respond to overcurrent conditions in seconds or microseconds, which gives them a huge advantage in protecting sensitive electronic components. Many solid-state fuses also feature voltage clamping and EMI suppression and are often used in very high-performance applications.

Advantages of Electronic Fuses

A. Faster response time

In that sense, electronic fuses have an edge over mechanical fuses because of their speed of response. While conventional fuses work on the principle of a metal conductor melting, electronic fuses rely on sophisticated circuitry to spot an overcurrent and respond almost instantaneously. Such rapid actions help prevent damage to sensitive electronic components and equipment by disconnecting the power supply within microseconds of noticing a problem.

B. Improved accuracy and precision

The digital character of electronic fuses affords immense accuracy and precision in current sensing and comprehension. They may contain calibrations far stricter than many conventional types, performing consistently across widely varying operating conditions. The improved accuracy means better protection for your electrical systems and lowers the issue of nuisance tripping or false alarms.

C. Programmability and customization

Another potent quality of electronic fuses is their programmability and customization according to specific applications' requirements. One can customize and fine-tune trip points, response curves, and more in response to the overall requirements of the circuits. This flexibility allows for optimized protection in various scenarios and can be easily updated as the system needs to change over time.

D. Self-diagnostic capabilities

Most electronic fuses come with self-diagnosing features, allowing the fuse to monitor its health and performance constantly. This mechanism can detect issues like internal failures and degradation, thus sending alerts to the user before a shutdown warning. Such active maintenance measures will inhibit unanticipated downtimes and bolster overall system reliability.

E. Longer lifespan

Since electronic fuses are reusable, they can be reset repeatedly. Therefore, spending more money on electronic fuses could soon prove cheaper by lessening maintenance costs and cutting downtime. Due to their solid-state construction, electronic fuses are generally less affected by environmental factors, such as temperatures and vibration. This will also contribute to the extension of their lifespan.

Applications of Electronic Fuses

A. Automotive industry

From a vehicle perspective, modern-day electronic fuses protect sensitive electronic components and systems from damage. They are mainly used in battery management systems, engine control units, and infotainment systems. Circuit breakers protect electrical circuits from further damage during overcurrent and short-circuit conditions.

B. Consumer electronics

Electronic fuses are used in consumer electronics to ensure the safe operation of laptops, mobile phones, and televisions from power surges and overloads. They ensure the longevity of the devices and safe use by the consumer. They are also highly useful in chargers and power adapters, as they can hold voltage fluctuations at a minimal level to avoid damage.

C. Industrial equipment

Electronic fuses serve a central role in protecting industrial equipment. They are generally found in control systems, motors, and automation equipment, all of which avert costly downtime and risks to safety. The fuses being used have to sustain extreme, harsh situational conditions in most environments across this engineering sector.

D. Power distribution systems

Electronic fuses are used primarily for grid stability and the imperative protection of high-value infrastructure in power distribution systems. They are used in substations, transformers, and switchgear to isolate faults, preventing widespread outages quickly. The rapid response time of electronic fuses is especially critical in such applications because even a minor power outage can have significant ramifications.

How Electronic Fuses Work

Current sensing mechanisms

Electronic fuses employ sophisticated current sensing mechanisms to detect overcurrent conditions. These mechanisms typically involve precision resistors or current transformers that continuously monitor the flow of electricity through the circuit. As current passes through these sensing elements, they generate a proportional voltage drop or magnetic field, which is then interpreted by the fuse's internal circuitry.

Triggering process

Current exceeding the preset threshold commences the trigger sequence of an electronic fuse. In other words, the process swiftly triggers a solid-state switch, like a MOSFET or thyristor, to break the circuit. The switch can open within a few microseconds, halting the current flow and safeguarding the connected apparatus from damage.

Reset functionality

One of the key advantages of electronic fuses is their reset functionality. Unlike traditional fuses that require replacement after failure, electronic fuses often allow for automatic or manual resetting. Automatic resetting can occur once the fault condition ceases and the current returns to normal. Some electronic fuses also have manual reset buttons, allowing users to reset them once the apparent fault condition has been eliminated. The convenience of resetting the fuse reduces downtime during product applications.

Selecting the Right Electronic Fuse

Current rating considerations

Generally, determining the fuse's current rating is an essential parameter in selecting an electronic fuse. Closely matching a fuse's current rating with the circuit is necessary to ensure adequate protection. Choosing a fuse rating slightly higher than the circuit's maximum operating current is generally practiced under normal conditions. This will allow brief current spikes without unnecessary tripping and sufficient protection against serious overcurrents.

Voltage requirements

Another significant consideration is the electronic fuse's voltage rating. The fuse must be able to withstand the maximum voltage that can appear on the circuit during normal operation and during fault conditions. Using a fuse with an insufficient voltage rating can cause it to arc over and fail to interrupt current flow during a fault. Such a failure can damage the equipment and pose safety hazards.

Environmental factors

Environmental conditions are decisive in selecting fuses: temperature, humidity, vibration, and exposure to corrosive materials, to name a few. Choose fuses with high-temperature ratings, as necessary. If subjected to vibration, use fuses built to withstand mechanical stress. Sealed or encapsulated fuses may be necessary in special applications requiring reliable operation and longevity.

Installation and Maintenance

Proper installation techniques

If electrofuses are installed in electrical circuits, ensure they are installed correctly and safely. Switch off the power first and disengage the circuit. The proper fuse is then inserted into its holders so that it is seated correctly and appropriately aligned. Verify the fuse rating against the electrical circuit. This ensures that the correct voltage and amperage ratings have been applied during that period.

Regular inspection procedures

Regular inspections are essential to keeping electrofuses functioning well. This should be done monthly and every six months to a year, depending on applications. Fuses should be visually inspected for discoloration, melting, or other physical damage during routine examinations. Make sure that the terminals are not loose or corroded. Using multimeters and catalogs to select fuses properly, one could establish the continuity and resistance values across the fuse terminals.

Troubleshooting common issues

In cases of fuse problems, check for the fundamental cause. The zapped fuse indicates that the circuit was overloaded or shorted. For instance, this can be excessive current draw or even defective components. So, in cases where fuses are blown quite often, use a higher-rated fuse or find the essential trouble in the affected circuit. Check for intermittent fuse function. Weak electrical connections or environmental changes such as humidity or temperature fluctuations can affect fuse function here.

Related Articles

Is a Fuse a Resistor? [Everything Explained]

How Does a Fuse Work? [Full Guide]

Impact of IRF3205 MOSFET on Power Electronics: Advancements and Applications

Top 10 Common Electronic Components Guide

Exploring Electronic Components: Innovations and Applications

Exploring Electronic Components(Guide)

What is an Electronic Speed Controller and How Does it Work?

The Ultimate Guide to CR1220 Battery

Motherboard: The Core of Computer Hardware

ATMega328P Microcontroller: A Powerful Microcontroller

2N3904 vs 2N2222:What You Need to know

Intelligent Sensors: Definition, Configurations, and Utilizations

TXB0104PWR Review: Overview, Features, and Applications